Types and types of car suspensions

Content

Pneumatic suspensions are used in modern cars of the brands Audi, Mercedes-Benz, BMW and Porsche. The pneumocylinder represents a special insert from polyurethane. The element is inside the spring. The main function is to enhance the properties of the spring while adjusting the stiffness. The control lever in this assembly is an artificial increase or decrease in pressure inside the air spring.

The suspension of a car or truck is the connecting link between the body of the car and the road. And it represents one or another type of suspension system. Depending on this, the types of car suspensions are also distinguished.

Car with what type of suspension to choose

When choosing a suspension, they are guided by the tasks of ensuring the comfort of driving. The functions of the node are aimed at this:

- decrease in tilt when cornering;

- ensuring smooth movement;

- support for the clarity of angles when installing wheels;

- effective and quick damping of body vibrations when the car drives through pits or bumps.

At the same time, with a stiff suspension, you will feel every road bump or pothole. What affects wear: shock absorbers responsible for damping vibrations need to be replaced every 60-000 km.

Soft suspensions have their advantages. The load on the driver's spine while driving is much less, the structure does not wear out so quickly. However, if you drive a car where the weight of passengers and luggage is concentrated on the side, then the body will roll more during the turn. Which can lead to loss of control.

The disadvantages of both systems are eliminated by adjusting the alignment. But the ideal balance is usually not achieved immediately.

Existing suspension types

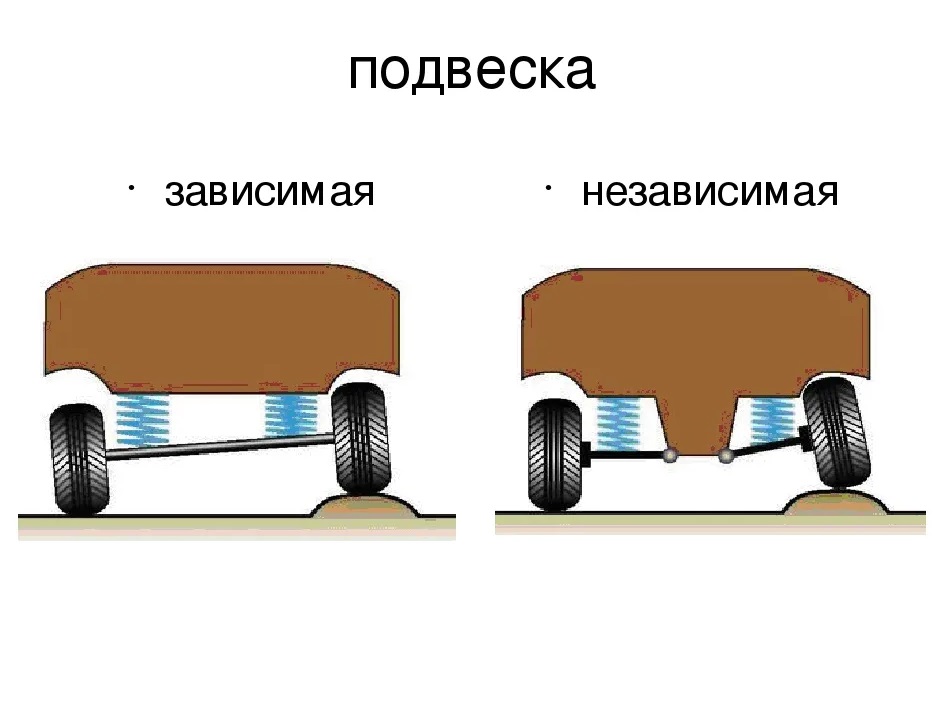

Separation of car suspensions soft and hard types - incomplete classification. Structures can be dependent or independent. In addition, in modern production, they prefer to use various suspension systems for the front and rear wheels.

Dependent suspensions

A suspension system is called dependent when both wheels are located on the same axis and are interconnected using a rigid beam.

Dependent suspensions

But when driving on smooth roads, dependent suspension has the advantage of providing even and consistent traction. In modern automotive production, this design is most often used on the rear wheels.

Independent suspensions

Independent suspensions are more common. The essence of the mechanism explains the name. The wheels move independently of each other.

The main advantages:

- The operation of suspensions on different sides of the axle does not depend on each other.

- The vehicle weight indicator is reduced due to the absence of heavy tie beams.

- There is a variety of design variations.

- The stability of the car's behavior is increased while improving its handling.

The combination of these advantages significantly increases the overall comfort rate during trips.

Types of independent suspensions

A variety of designs of independent suspension systems has led to the formation of a detailed classification. Types of car suspensions of an independent type are divided into lever and alternative.

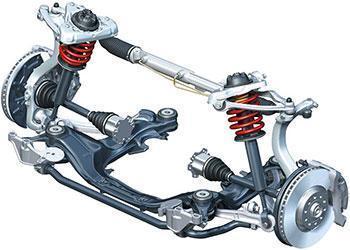

Double wishbone front suspension

The shock absorber with a spring in the design is mounted separately.

The upper arm with a ball joint is screwed to the steering knuckle. Since the ball joints are installed at the ends of the levers, the rotation of the wheel is carried out using the steering rod.

The design does not have a support bearing, which eliminates the rotation of the elements when the wheel turns. Design features allow you to evenly distribute static and dynamic loads on each of the elements. Due to this, the operational life of the part is increased.

Double wishbone front suspension

A double wishbone suspension is installed on SUVs or premium cars.

Air suspension

This is a system where the function of uniform distribution of loads is performed by special pneumocylinders made of rubberized material. The main advantage is the smoothness of the car. Most often, air suspensions are installed on premium cars or heavy vehicles.

hydraulic suspension

Hydraulic suspension is a system where hydraulic struts or hydraulic lifts are used instead of shock absorbers.

When the engine starts, a hydraulic pump supplies fluid to the control box. As a result, it allows you to maintain a given height of the car at the same level. For the first time, hydraulic suspension was used in the production of Citroen cars.

Types of car suspensions

For passenger cars, combinations of several schemes are used. The best option is to install a dependent system on the rear wheels and a movable structure in front.

Spring

This is a mechanical suspension with elastic elements - leaf springs. The advantage of the scheme is considered to be resistance to overloads and poor road surfaces.

There is no need to install additional elements and complex devices. But there is one significant drawback - this is the fragility of such a design. With the constant transportation of goods or the use of trailers, the springs sag. Then while driving you will hear a creaking or rattling.

With guide levers

Demanded type of suspension. The levers set the direction of the drive axle during movement. In order for the suspension system to work well, the upper links are set at an angle. This technique increases the stability of the car during turns.

With support pipe or drawbar

In this scheme, the load is assumed by a part of the pipe protecting the universal joint. In order for the structure to work without failures, the cardan passing through the gearbox is rigidly fixed to the front of the bridge beam. The result of using this scheme is a smooth ride and ride comfort.

De Dion

This system belongs to dependent suspended structures. The wheels are connected by a beam, and the main gear reducer is fixed to the body. To improve the handling of the wheels, they are mounted at a slight angle.

Torsion

The second name of this system is the core system. Working elements - rods or torsion bars having different sections. For the manufacture of the latter, spring steel is also used. This design enhances the grip properties of the wheels with the road surface.

With swinging axle shafts

The scheme for assembling a system with oscillating semi-axes involves installation at the ends. The role of the elastic element is performed by springs or autosprings. The advantage of the system is the stabilization of the position of the wheel relative to the axle shaft.

On trailing arms

This is an alternative design, where the wheels are attached to a lever located along the longitudinal axis of the vehicle. The system is patented by Porsche. However, at present, it is almost never used as a basis.

Spring

Scheme for both independent and dependent suspensions. Springs of a conic form soften the course of the car. Driving safety directly depends on the quality of the installed springs.

Dubois

The design consists of springs, shock absorbers, as well as a cylindrical casing. The main advantage of the system is smooth and hassle-free braking.

On double trailing arms

The design feature is that the rods are installed on the sides of the machine. This scheme is suitable for vehicles with aft engine.

On slanting levers

This is a modification of the design described above. The change affected the location of the rods. Placed at a predetermined angle relative to the axis, they help to minimize the amount of roll when turning.

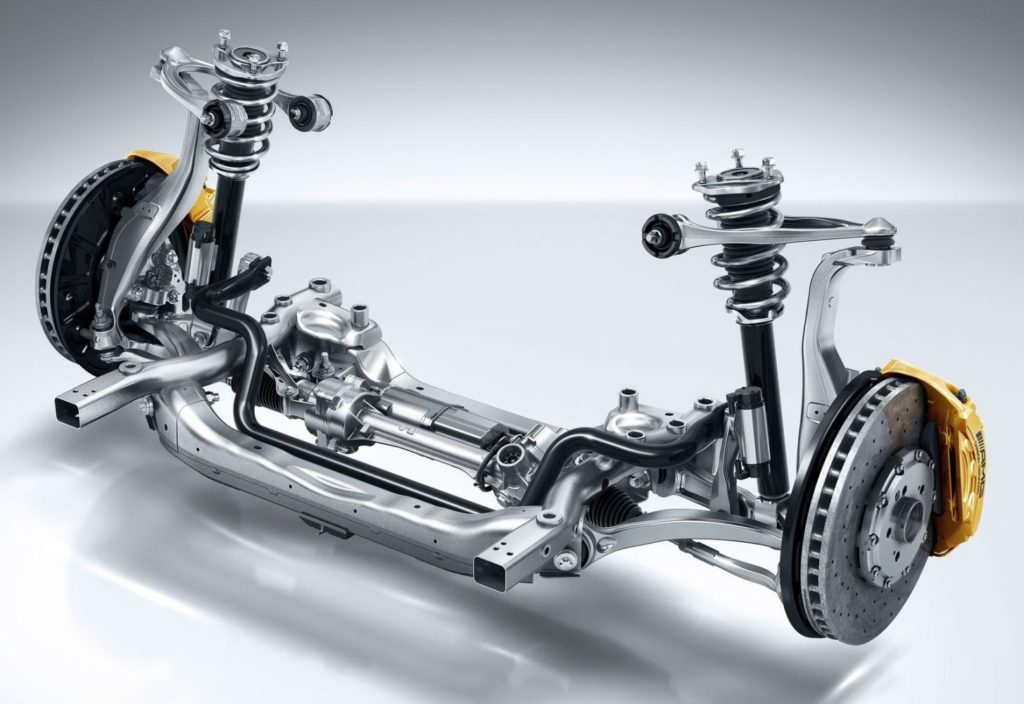

Wishbone suspension

On double wishbones

The ends of the transverse rods installed along the sides of the machine are movably mounted on the frame. This suspension can be mounted front or rear.

On rubber elastic elements

The coil springs in this scheme are replaced by blocks made of durable rubber. Despite the stability, the suspension has a low wear resistance.

Hydropneumatic and pneumatic

The elastic elements in these structures are pneumocylinders or hydropneumatic elements. United by one control mechanism, they simultaneously maintain the size of the lumen.

Multi-link

The multi-link system is most often used on rear-wheel drive vehicles. Assembly involves the use of double transverse rods. This method of fastening effectively changes the geometry while the car is moving.

Candle

An autospring acts as an elastic element in this scheme. It is installed across the axis. This fastening of the guide allows the steering knuckle with the spring to move vertically, which contributes to smooth cornering. The system is reliable and compact in size. If the wheel encounters an obstacle, it moves up. The assembly scheme is complex, so it is used infrequently.

Pneumatic suspensions

Pneumatic suspensions are used in modern cars of the brands Audi, Mercedes-Benz, BMW and Porsche. The pneumocylinder represents a special insert from polyurethane. The element is inside the spring. The main function is to enhance the properties of the spring while adjusting the stiffness. The control lever in this assembly is an artificial increase or decrease in pressure inside the air spring.

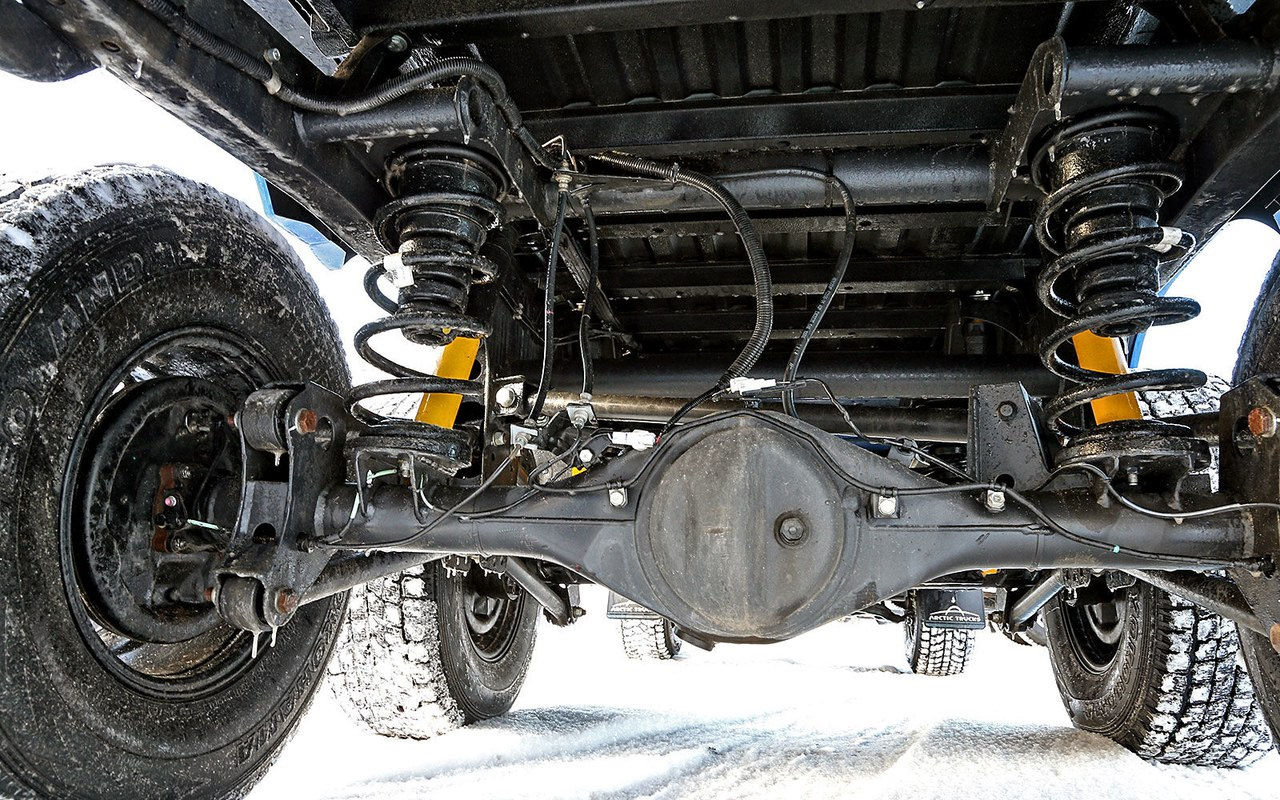

Suspensions for pickups and SUVs

Most often for jeeps use a whole range of suspension systems.

Suspensions for pickups and SUVs

The following options are popular:

- rear dependent and front independent systems;

- more dependent suspension;

- independent suspension front and rear.

Usually, the rear axle of jeeps is equipped with spring or spring suspensions. These are reliable and unpretentious designs that can withstand different loads. The front axle is fixed with torsion or dependent springs. Equipping pickups and SUVs with only rigid dependent bridges today is a rarity.

Truck suspensions

For trucks, dependent suspension systems are used, as well as hydraulic shock absorbers of the assembly type. These are the simplest node options.

When assembling a suspended structure for trucks, the main role of the regulator is assigned to the springs connecting the axle and wheels, and also acting as the main guide element.

Suspensions on sports cars

It is believed that a rigid suspension makes the movement of the car safe and maneuverable. Because of this, sports cars are equipped with only such a suspension system.

Thus, the types of car suspensions are conventionally divided into 2 types: dependent or independent assembly. Each group has its own classifications according to the type of elements, functionality or design features.