4JM hydrogen engine

Content

In search of new, cheaper sources of energy for transportation, human thought came up with the idea of using hydrogen as a fuel for refueling wheeled vehicles. Despite the fact that the idea is not new (the first hydrogen internal combustion engine was created in 1806 by the Frenchman Francois De Rivas), engineers came to the industrial use of the lightest gas in fuel cells, internal combustion engines and gas turbine engines only at the beginning of the new, XXI century.

How a hydrogen engine works

The main reason for the search for a new source of energy for car engines was the urgent need to reduce harmful emissions. Modern technologies for cleaning spent fuel can reduce emissions to hundreds of grams per kilometer. But the situation is aggravated by the uncontrolled growth in the number of cars on the roads: the swelling car flow levels the quality of modern technologies for removing the oxygen-carbon mixture.

The most promising direction in the development of hydrogen technology is the use of fuel cells. They are able to produce electricity, located directly on board the vehicle. Among others, engineers of the Japanese automobile corporation Toyota Motor Corporation are developing a hybrid hydrogen engine. In 2014, under this appeared the world's first mass-produced hydrogen car - Mirai (translated from Japanese - "future").

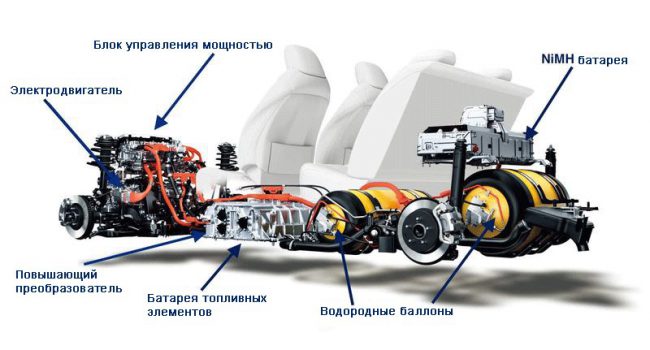

The Toyota Mirai power plant is hybrid, it includes three components:

- fuel cell stack TFCS;

- high pressure hydrogen cylinders;

- boost converter.

The battery is capable of producing 114 kW of power, which is DIN equivalent to 155 hp. The specific power of the TFCS battery (3,1 kW / l) is more than 2 times higher than the first option developed by Toyota engineers - FCHV-advantage.

4JM is the best hydrogen engine in the world

It should be noted that the chemical reaction to generate electrical energy occurs without combustion, thereby increasing the environmental friendliness of an already absolutely “clean” electric motor. The energy conversion in the 4JM motor is 83% efficient. The engine is equipped with a secondary nickel-cadmium battery in the form of a 21 kW battery.

4JM is a synchronous AC motor. During regenerative braking, the battery stores the electricity returned to the grid, which is generated by the traction motor in generator mode.

With the help of a converter, the voltage obtained on the elements is increased to 650 V. This is necessary in order to reduce the geometric parameters of the electric motor and the number of fuel cells, to compactly fit the components of the system inside the car. Direct current is converted to alternating current by an inverter. In the process of refueling, hydrogen is pumped into the tank through a coal filtration system. When moving through the air intakes, air from the atmosphere enters the battery.

A chemical reaction with hydrogen begins, the result of which is the production of electrical energy. When you press the accelerator, it is supplied from the battery to the motor. Chemistry experts will immediately determine that the only by-product in this chain is water formed as a result of a chemical reaction. Its removal is carried out through the exhaust pipe.

The location of the battery and high-pressure hydrogen cylinders in the center of the machine, coupled with the optimal settings of the electric motor, provide optimal power management. The result is a machine that is more responsive to driver input at any speed, delivering more torque and smoother acceleration. In the reverse order, the braking procedure takes place.

The geometry of the machine is designed in such a way as to provide the lowest possible center of gravity, optimal weight distribution of the front and rear parts of the body and the overall maximum rigidity of the structure.

The number of hydrogen tanks is 2 (60 and 62,4 liters, respectively). The gas is stored in them under pressure of 70 MPa. The maximum mass of hydrogen pumped into the tank for 3 minutes is 5 kg. This allows you to drive up to 650 kilometers on one gas station, developing a maximum speed of 175 km / h.

Is everything so cloudless in hydrogen technology

The service life of one fuel cell operating on hydrogen is up to 10 years. There are no noises and vibrations characteristic of internal combustion engines in the operation of the engine. Motors are absolutely clean from an environmental point of view. However, criticism of hydrogen-fuelled transport research is extensive. Apologists for traditional energy sources for wheeled vehicles and developers of conventional electric motors are pushing hydrogen, pointing to a number of intractable issues in the field of infrastructure and technology.

Critics of hydrogen transport point to the lack of standards in the production, storage, movement and use of hydrogen. A significant volume of fuel tanks for long trips reduces the capacity of the passenger compartment and trunk. There are purely technological factors associated with the danger of improper handling of hydrogen storage and injection equipment. It is extremely volatile: the slightest gap in the design of tanks and systems for supplying hydrogen to the place of a chemical reaction can lead to closed filling of the car interior and ignition.

In short, there are enough problems to be solved on the way to the safe and economical mass use of hydrogen for refueling vehicles. The main question is whether the owners of auto corporations are ready to invest heavily in the development of new infrastructure, further theoretical research and practical development. Indeed, today refueling vehicles on the road (that is, without visiting special gas stations) is impossible.

Money is the basis of everything

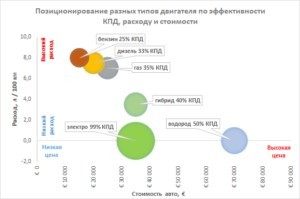

The main “minus” is the complexity of the process of producing such a huge amount of hydrogen, which will be needed during the mass transfer of cars to new fuel. Today it is expensive to produce hydrogen, both from natural gas and by electrolysis. Thus, the cost of mileage on a car with a hydrogen engine is much more expensive than on gasoline or diesel fuel.

At the moment, refueling 120 liters of hydrogen in a pair of high-pressure tanks, car owners have to shell out 960 euros. It is very expensive compared to gasoline or diesel fuel. Not every average resident of the developed countries of Europe, Asia or America can afford to afford to buy such a car and constantly move around on it, winding up considerable “ends”. So far, Toyota Mirai is an expensive copy for a car collection, or a vehicle for moneybags who are not used to counting money.

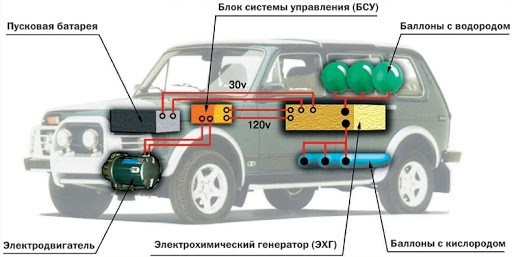

A partial solution to the issue could be a hybrid engine, in which the second fuel is traditional gasoline or diesel fuel. To carry out such tuning manually, you need to install a starting battery, BSU, hydrogen and oxygen cylinders. Electrical part of tuning:

- electrochemical generator (ECG);

- electric motor;

- starting battery.

The raw material for producing hydrogen is drinking water poured into a tank for electrolysis. The source of energy is a generator. The gas is produced in a small amount, then sent to the intake manifold of the internal combustion engine. There, hydrogen is mixed with gasoline and then burned. However, the energy consumption for hydrogen production on the way, and its quantity do not allow us to talk about the efficiency of such installations.

Despite the fact that cars with hybrid installations on hydrogen fuel and electric motors are closest in design, philosophy of use and technology to conventional electric vehicles, the apologists of the latter are the main critics of the new energy source. Apparently, in the future, the costs of solving all issues will be negligible compared to the income from sales of hydrogen cars. If, of course, all obstacles can be overcome.