Engine air intake: how does it work?

Content

To cause combustion in a heat engine, two key elements are needed: fuel and an oxidizer. Here we will focus on observing how the oxidant enters the engine, namely the oxygen present in the air.

An example of air intake from a modern engine

Air supply: what path does the oxidizer take?

The air that is directed into the combustion chamber must pass through a circuit, which has several defining elements, let's now see them.

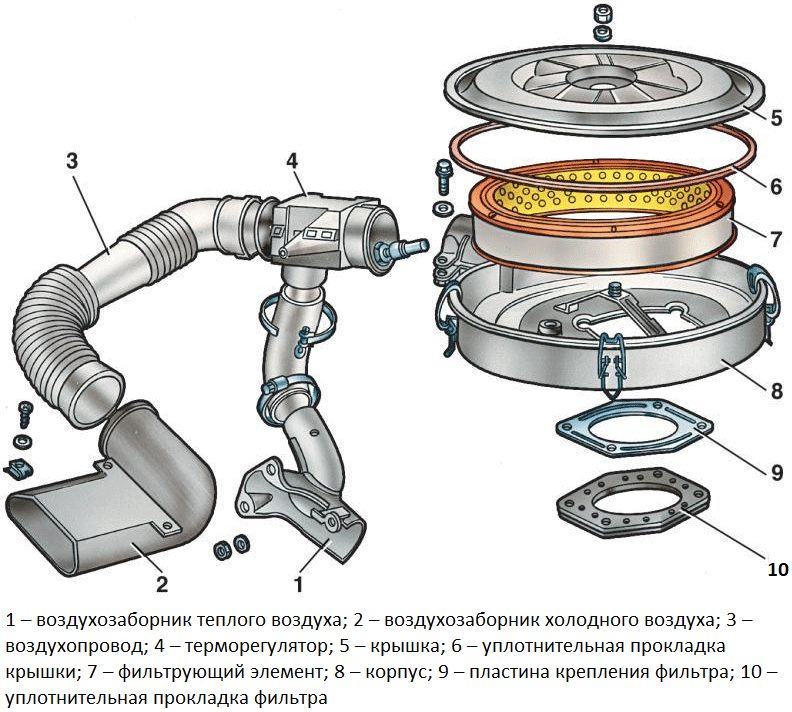

1) Air filter

The first thing that oxidizer enters the engine is the air filter. The latter is responsible for capturing and holding as many particles as possible so that they do not damage the internals of the engine (combustion chamber). However, there are several air filter settings/calibers. The more particles the filter traps, the more difficult it is for the air to pass through: this will slightly reduce the power of the engine (which will then become a little less breathable), but improve the quality of the air that will enter the engine. (less parasitic particles). Conversely, a filter that passes a lot of air (high flow rate) will improve performance but allow more particles to enter.

It needs to be changed regularly because it gets clogged.

2) Air mass meter

In modern engines, this sensor is used to indicate in the engine ECU the mass of air entering the engine, as well as its temperature. With these parameters in your pocket, the computer will know how to control the injection and throttle (petrol) so that combustion is perfectly controlled (air / fuel mixture saturation).

When it gets clogged, it no longer sends correct data to the computer: power off in the dongle.

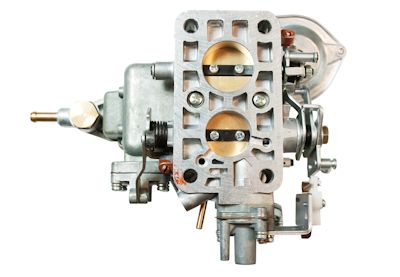

3) Carburetor (old gasoline engine)

Older gasoline engines (before the 90s) have a carburetor that combines two functions: mixing fuel with air and regulating the flow of air to the engine (acceleration). Adjusting it can sometimes be tedious ... Today, the computer itself doses the air / fuel mixture (so your engine now adapts to changes in atmospheric conditions: mountains, plains, etc.).

4) Turbocharger (optional)

Designed to increase engine performance by allowing more air to flow into the engine. Rather than being limited by the engine's natural intake (piston movement), we are adding a system that will also "blow" a lot of air inward. In this way, we can also increase the amount of fuel and therefore the combustion (more intensive combustion = more power). The turbo works well at high revs because it is powered by the exhaust gases (more importantly at high revs). The compressor (supercharger) is identical to the turbo, except that it is driven by the power of the engine (it suddenly starts spinning slower, but runs earlier at RPM: the torque is better at low RPM).

There are static turbines and variable geometry turbines.

5) Heat exchanger / intercooler (optional)

In the case of a turbo engine, we necessarily cool the air supplied by the compressor (hence the turbo), because the latter was slightly heated during compression (the compressed gas heats up naturally). But above all, cooling the air allows you to put more in the combustion chamber (cold gas takes up less space than hot gas). Thus, it is a heat exchanger: the air to be cooled passes through a compartment adhered to the colder compartment (which itself is cooled by fresh outside air [air / air] or water [air / water]).

6) Throttle valve (gasoline without carburetor)

Gasoline engines work by very precise mixing of air and fuel, so a butterfly damper is required to regulate the air entering the engine. A diesel engine operating with excess air does not need it (modern diesel engines have it, but for other, almost anecdotal reasons).

When accelerating with a gasoline engine, both air and fuel must be dosed: a stoichiometric mixture with a ratio of 1 / 14.7 (fuel / air). Therefore, at low revs, when little fuel is needed (because we need a trickle of gas), we must filter the incoming air so that there is no excess of it. On the other hand, when you accelerate on a diesel, only the fuel injection into the combustion chambers changes (on turbocharged versions, the boost also starts sending more air into the cylinders).

7) intake manifold

The intake manifold is one of the last steps in the intake air path. Here we are talking about the distribution of air that enters each cylinder: the path is then divided into several paths (depending on the number of cylinders in the engine). The pressure and temperature sensor allows the computer to control the engine more precisely. Manifold pressure is low on petrols with low load (throttle not fully open, poor acceleration), while on diesels it is always positive (> 1 bar). To understand, see more information in the article below.

On gasoline with indirect injection, the injectors are located on the manifold to vaporize the fuel. There are also single-point (older) and multi-point versions: see here.

Some elements are connected to the intake manifold:

- Exhaust Gas Recirculation Valve: On modern engines there is an EGR valve, which allows some of the gases to be recirculated. to intake manifold so that they pass in the cylinders again (reduces pollution: NOx by cooling the combustion. Less oxygen).

- Breather: Oil vapor escaping from the crankcase returns to the intake port.

8) Inlet valve

In the last step, air enters the engine through a small door called an intake valve that opens and closes continuously (in accordance with a 4-stroke cycle).

How does the calculator confuse correctly?

The engine ECU allows for accurate metering of all "ingredients" thanks to the information provided by various sensors / probes. The flow meter shows the incoming air mass and its temperature. The intake manifold pressure sensor allows you to find out the boost pressure (turbo) by adjusting the latter with a wastegate. The lambda probe in the exhaust makes it possible to see the result of the mixture by studying the power of the exhaust gases.

Topologies / Assembly Types

Here are some assemblies by fuel (gasoline / diesel) and age (more or less old engines).

Old engine сущность atmospheric à

carburetor

Here's a pretty old naturally aspirated gasoline engine (80s / 90s). Air flows through the filter and the air / fuel mixture is carried away by the carburetor.

Old engine сущность turbo à carburetor

engine сущность modern atmospheric injection indirect

Here the carburetor is replaced with a throttle valve and injectors. Modernism means that the engine is electronically controlled. Therefore, there are sensors to keep the computer up to date.

engine сущность modern atmospheric injection guide

The injection is direct here because the injectors are directed directly into the combustion chambers.

engine сущность modern turbo injection guide

On a recent gasoline engine

engine diesel injection guide et indirect

In a diesel engine, the injectors are directly or indirectly placed in the combustion chamber (indirectly there is a prechamber connected to the main chamber, but there is no injection into the inlet, as on gasoline with indirect injection). See here for more explanations. Here, the diagram is more likely to refer to older versions with indirect injection.

engine diesel injection guide

Modern diesels typically have direct injection and superchargers. Added a whole bunch of items for cleaning (EGR valve) and electronically controlling the engine (computer and sensors)

Petrol engine: intake vacuum

As you probably already know, the intake manifold of a gasoline engine is under low pressure most of the time, that is, the pressure is between 0 and 1 bar. 1 bar is (roughly) the atmospheric pressure on our planet at ground level, so this is the pressure we live in. Also note that there is no negative pressure, the threshold is zero: absolute vacuum. In the case of a gasoline engine, it is necessary to limit the air supply at low speeds so that the oxidizer / fuel ratio (stoichiometric mixture) is maintained. However, be careful, then the pressure becomes equal to the pressure in our lower atmosphere (1 bar) when we are fully loaded (throttle full: throttle open to maximum). It will even exceed the bar and reach 2 bar if there is boost (a turbo that blows air out and eventually pressurizes the intake port).

School enrollment DIESEL

On a diesel engine, the pressure is at least 1 bar, since the air flows as it wants at the inlet. Therefore, it should be understood that the flow rate changes (depending on the speed), but the pressure remains unchanged.

School enrollment ESSENCE

(Low load)

When you accelerate a little, the throttle body doesn't open very much to restrict airflow. This causes a kind of traffic jam. The engine draws in air from one side (right), while the throttle valve restricts the flow (left): a vacuum is created at the inlet, and then the pressure is between 0 and 1 bar.

At full load (full throttle), the throttle valve opens to maximum and there is no clogging effect. If there is turbocharging, the pressure will even reach 2 bar (this is approximately the pressure that is in your tires).

All comments and reactions

Dernier comment posted:

Author (Date: 2021 08:15:07)

definition of radiator outlet

Il I. 1 reaction (s) to this comment:

- Administrator SITE ADMINISTRATOR (2021-08-19 11:19:36): Are there zombies on the site?

(Your post will be visible under the comment after verification)

Write a comment

Which French brand can compete with German luxury?

One comment

Erol Aliyev

defacto with gas injection installed if it sucks air from somewhere there will not be a good mixture and good combustion and there will be a difficult initial start