All information about Dsg gearbox

Content

On the cars of the Volkswagen concern, a robotic DSG box is used, but not all owners understand what it is and how to handle the assembly. Before buying a car, a car enthusiast needs to familiarize himself with the design of a preselective transmission, which replaces classic mechanical units. The reliability of the "robot" DSG directly depends on the operating modes.

What is DSG

The abbreviation DSG stands for Direkt Schalt Getriebe, or Direct Shift Gearbox. The design of the unit uses 2 shafts, providing rows of even and odd speeds. For smooth and fast gear shifting, 2 independent friction clutches are used. The design supports the dynamic acceleration of the machine while improving driving comfort. The increase in steps in the gearbox allows you to optimally use the capabilities of the internal combustion engine while reducing fuel consumption.

History of creation

The idea of creating gearboxes with a preliminary stage selection appeared at the beginning of the last century, Adolf Kegress became the author of the design. In 1940, a 4-speed gearbox developed by engineer Rudolf Frank appeared, which used a double clutch. The design of the unit made it possible to switch stages without breaking the power flow, which was in demand on the commercial equipment market. The designer received a patent for his invention, prototypes were made for testing.

At the end of the 70s. a similar design was proposed by Porsche, which developed the 962C racing car project. At the same time, the same box with a dry double clutch was used on Audi rally cars. But the further introduction of units was hampered by the lack of electronics capable of controlling the operation of clutches and gear shifting.

The advent of compact controllers has led to the development of a dual clutch transmission for mid-range machines. The first version of the classic DSG box with 2 clutches was launched into mass production at the end of 2002. Borg Warner and Temic, which supplied the clutch, hydraulics and control electronics, took part in the creation of the assembly. The units provided 6 forward speeds and were equipped with a wet clutch. The product received the factory index DQ250 and allowed the transfer of torque up to 350 N.m.

Later, a 7-speed dry type DQ200 appeared, designed for engines with a torque of up to 250 N.m. By reducing the capacity of the oil sump and the use of compact drives, the size and weight of the transmission have been reduced. In 2009, an improved wet type DQ500 gearbox was launched, adapted for use on machines with front or all-wheel drive.

How it works

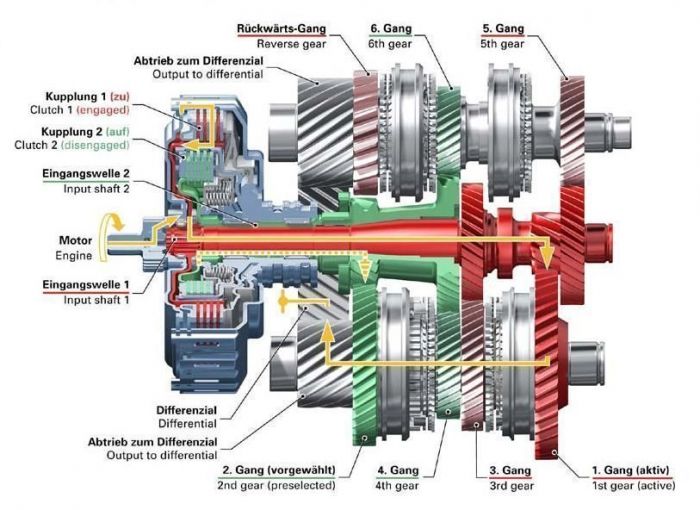

The DSG box consists of a mechanical part and a separate mechatronics unit that provides a choice of speeds. The principle of operation of the transmission is based on the use of 2 clutches, which allows you to smoothly shift up or down. At the moment of switching, the first clutch is disengaged and at the same time the second clutch unit is closed, which eliminates shock loading.

In the design of the mechanical module, there are 2 blocks that ensure the operation of an even and odd number of speeds. At the moment of start, the box includes the first 2 steps, but the overdrive clutch is open.

The electronic controller receives information from the rotation sensors, and then switches the speeds (according to a given program). For this, standard couplings with synchronizers are used, the forks are driven by hydraulic cylinders located in the mechatronics unit.

The crankshaft of the motor is connected to a dual-mass flywheel, which transmits torque through a spline connection to the hub. The hub is rigidly mated to the dual clutch drive disc, which distributes torque between the clutches.

The same gears are used to ensure the operation of the first forward and reverse gears, as well as 4 and 6 forward gears. Due to this design feature, it was possible to reduce the length of the shafts and the assembly assembly.

Types of DSG

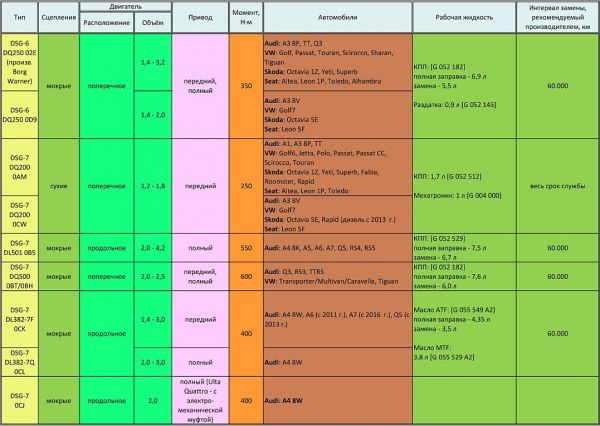

VAG uses 3 types of boxes on cars:

- 6-speed wet type (internal code DQ250);

- 7-speed wet type (manufacturer code DQ500 and DL501, designed for transverse and longitudinal mounting, respectively);

- 7-speed dry type (code DQ200).

DSG 6

The design of the DSG 02E box uses clutches with working discs rotating in an oil bath. The fluid provides a reduction in friction lining wear with a simultaneous decrease in temperature. The use of oil has a positive effect on the resource of the unit, but the presence of liquid in the crankcase reduces the efficiency of the transmission and leads to an increase in fuel consumption. The oil reserve is about 7 liters, the lower part of the gearbox housing is used for storage (the design is similar to mechanical transmissions).

Additional features implemented in the dry type box:

- sports mode;

- manual switching;

- Hillholder mode, which allows you to stop the car by increasing the pressure in the clutch circuit;

- support for movement at low speed without driver intervention;

- maintaining vehicle mobility during emergency operation.

DSG 7

The difference between the DQ200 and previous versions of the box was the use of dry-type friction clutches and 2 separated oil systems designed to lubricate the mechanical section of the transmission and to operate the hydraulic mechatronic circuits. Fluid is supplied to the mechatronic actuators by means of a separate electrically driven pump, which pumps oil into the supply tank. The separation of lubrication and hydraulic systems made it possible to neutralize the negative effect of wear products on solenoids.

The control sensors are integrated into the control controller, which made it possible to avoid the installation of additional wiring. The box supports all modes implemented in the units of the previous generation. Hydraulics is divided into 2 sections serving even and odd gears.

The DQ500 unit differs from the DQ250 in the appearance of an additional forward gear. The box device uses a flywheel of a modified design, as well as clutches designed for increased torque. The use of advanced mechatronics made it possible to speed up the process of switching speeds.

What cars can be found

DSG transmissions can be found in Volkswagen, Skoda, Seat or Audi cars. An early version of the DQ250 box was used on Volkswagen cars manufactured after 2003. The DQ200 version was used on cars such as the Golf or Polo. You can determine the presence of a DSG box by the emblem located on the shift handle.

But since 2015, the Volkswagen concern has abandoned such markings on the levers, the type of transmission is determined by the appearance of the box (on the side of the crankcase there is a mechatronics unit with a protruding filter cover).

Typical problems

The weak link in the design of the boxes is the mechatronics, which changes entirely. The failed unit is restored in specialized workshops or in the factory. In early versions of the wet-type gearbox, wear products of the friction linings get into the liquid.

The filter provided in the design becomes clogged with dirt particles; during long-term operation, the unit does not provide oil purification. Fine dust is drawn into the shift control unit, causing abrasive wear to the cylinders and solenoids.

The wet clutch life is affected by the torque of the motor. The service life of the clutch is up to 100 thousand km, but if a reprogrammed engine control unit is used, then the mileage before replacement drops by 2-3 times. Dry friction clutches in the DSG7 serve an average of 80-90 thousand km, but increasing power and torque by flashing the motor controller reduces the resource by 50%. The complexity of replacing worn-out elements is the same, for repair it is required to remove the gearbox from the car.

In DQ500 boxes, there is a problem with oil ejection through the vent hole. To eliminate the defect, an extension hose is put on the breather, which is attached to a small volume container (for example, to a reservoir from a clutch cylinder from VAZ cars). The manufacturer does not consider the defect critical.

What breaks in the DSG box

Common breakdowns of DSG gearboxes:

- In DQ200 units, the electronic control unit may fail. The defect is observed on boxes of early series due to the unsuccessful design of printed circuit boards on which the tracks depart. On DQ250 models, a failure of the controller leads to the activation of the emergency mode at the time of starting the motor, after turning off and restarting the defect disappears.

- Used in a dry box, an electric pump operates on signals from pressure sensors. If the tightness is lost, the circuit does not hold pressure, which provokes the constant operation of the pump. Long-term operation of the engine causes overheating of the windings or rupture of the storage tank.

- To shift gears, the DQ200 used forks with a ball joint, which collapses during operation. In 2013, the box was modernized, finalizing the design of the forks. To extend the life of old-style forks, it is recommended to change the gear oil in the mechanical section every 50 thousand kilometers.

- In DQ250 units, wear of the bearings in the mechanical block is possible. If the parts are damaged, a hum appears when the car is moving, which varies in tone depending on the speed. A damaged differential begins to make noise when turning the car, as well as during acceleration or braking. Wear products enter the mechatronics cavity and disable the assembly.

- The appearance of a clang at the time of starting the engine or during idle mode indicates the destruction of the structure of the dual-mass flywheel. The assembly cannot be repaired and is replaced with the original part.

https://www.youtube.com/watch?time_continue=2&v=5QruA-7UeXI&feature=emb_logo

Advantages and disadvantages

Advantages of DSG transmission:

- ensuring accelerated acceleration due to the short time of switching speeds;

- reduced fuel consumption regardless of the driving mode;

- smooth gear shifting;

- possibility of manual control;

- maintenance of additional modes of operation.

The disadvantages of cars with DSG include an increased cost compared to analogues equipped with a manual transmission. The mechatronics installed on the boxes fails due to temperature changes; in order to restore the box's performance, you will need to install a new unit. On dry-type units, jerks are noted when switching the first 2 speeds, which cannot be eliminated.

The DSG transmission is not designed for aggressive driving because shock loads destroy the dual mass flywheel and friction clutches.

Is it worth taking a car with DSG

If the buyer needs a car without a run, you can safely choose a model with a DSG box. When buying a used car, you need to check the technical condition of the unit. A feature of DSG boxes is the ability to conduct computer diagnostics, which will determine the condition of the node. The check is performed using a cord that is attached to the diagnostic block of the machine. To display information, the software "VASYA-Diagnost" is used.