Rear axle VAZ 2107: features of operation and maintenance

Content

The rear axle is a fairly reliable unit of the VAZ 2107 car, but, despite its massive appearance, the mechanism requires regular maintenance, without which it can fail prematurely. This unit can serve for a long time if it is operated correctly and carefully, if possible avoiding the extreme driving modes of the vehicle. Calm and careful driving without sharp pressure on the gas and brake pedals, hard clutch engagement and similar overloads will contribute to the serviceability and durability of the rear axle.

Rear axle functions VAZ 2107

The seventh VAZ model completes the line of rear-wheel drive cars produced by the Volga Automobile Plant: all subsequent models, starting with the VAZ 2108, were equipped with front or all-wheel drive. Thus, the torque from the engine of the "seven" through other elements of the transmission is transmitted to the rear wheels. The rear axle is one of the components of the transmission, including the differential and final drive. The differential is used to distribute torque between the axle shafts of the rear wheels when the car turns or moves on rough roads. The main gear amplifies the torque, which is transmitted to the axle shaft through the clutch, gearbox and cardan shafts. If the resulting torque is taken as 1, then the differential can distribute it between the axle shafts in a ratio of 0,5 to 0,5 or in any other, for example, 0,6 to 0,4 or 0,7 to 0,3. When this ratio is 1 to 0, one wheel does not rotate (for example, it fell into a hole), and the second wheel slips (on ice or wet grass).

Technical specifications

The rear axle of the "seven" has the following parameters:

- length - 1400 mm;

- differential diameter - 220 mm;

- stocking diameter - 100 mm;

- the gear ratio is 4,1, that is, the ratio of the teeth of the driven and driving gears is 41 to 10;

- weight - 52 kg.

What does the rear axle consist of?

The design of the rear axle "seven" includes a fairly large number of elements, including:

- Brake drum mounting bolts.

- Guide pins.

- Semi-shaft bearing oil baffle.

- Brake drum.

- Drum ring.

- Rear brake cylinder.

- Connection for bleeding the brakes.

- Axle bearing.

- Bearing circlip.

- Bridge girder flange.

- Stuffing box.

- Spring support cup.

- Bridge beam.

- Suspension bracket.

- Axle guide.

- Differential bearing nut.

- Differential bearing.

- Differential bearing cover.

- Breather.

- Satellite.

- Final drive pinion.

- Left semi-axis.

- Axle gear.

- Reducer housing.

- Drive gear adjusting ring.

- Spacer sleeve.

- Pinion bearing.

- Stuffing box.

- Dirt reflector.

- Universal joint yoke flange.

- Nut.

- Oil deflector.

- Final drive pinion.

- The axis of the satellites.

- Semi-axle gear support washer.

- Differential box.

- Right semi-axis.

- Axle brackets.

- Axle bearing thrust plate.

- Rear brake shield.

- Rear brake shoe.

- Friction pad.

- Axle flange.

- Stop plate.

- Bearing cover retaining bolts.

Chassis

All working mechanisms of the rear axle are located in the beam, as well as in the gearbox housing. The beam is made of two casings connected by longitudinal welding. The bearings and seals of the axle shafts are located in the flanges at the ends of the beam. In addition, suspension fasteners are welded to the beam body. In the middle, the beam is expanded and has an opening in which the gearbox housing is fixed. A breather is installed in its upper part, through which the connection of the bridge cavity with the atmosphere is maintained, due to which the pressure in the cavity does not rise above the permissible level and dirt does not get inside the part.

Reducer

The main gear consists of driving and driven gears with hypoid gearing, i.e., the gear axes do not intersect, but cross. Due to the specific shape of the teeth, the simultaneous engagement of several of them at once is ensured and, as a result, the load on the teeth is reduced and their durability is increased.. A two-satellite bevel differential, in addition to satellites located on a common axis, includes a box and two gears, while the satellites are in constant engagement with the gears.

Half-shafts

The "Seven" is equipped with the so-called semi-unloaded axle shafts of the rear axle, which take on bending forces both in the horizontal and vertical planes. The axle shaft, in fact, is a shaft made of 40X steel, on the inner end of which there are splines, on the outer end there is a flange. The inner end of the axle shaft is connected to the differential gear, the outer end is located in the flange of the beam, to which the brake drum and wheel are attached. The thrust plate of the bearing, which is also fixed to the beam, allows the axle shaft to be held in place.

Symptoms of a malfunction

As soon as the driver noticed any changes in the operation of the rear axle (for example, there were extraneous sounds that were not there before), he must react to these changes as quickly as possible so as not to aggravate the possible malfunction. The most common symptom of these problems may be increased noise levels:

- coming from the rear wheels;

- during the operation of the rear axle;

- when accelerating the car;

- when braking by a motor;

- when accelerating and braking by the motor;

- while the vehicle is turning.

In addition, a knock at the start of a car's movement and oil leakage may indicate a malfunction of the rear axle.

Grinding sound when moving

The reasons for the grinding noise from the rear axle when the vehicle is moving can be:

- wear or destruction of semi-axle or differential bearings;

- deformation of the beam or semiaxes;

- improper adjustment, damage or wear of gears or bearings of the gearbox and differential;

- wear of splined connection with half-axle gears;

- incorrect adjustment of the meshing of the teeth of the gears of the main drive;

- insufficient amount of oil.

The cardan is spinning, but the car does not go

If the propeller shaft rotates, and the machine is at the same time standing still, the cause may be a failure of the spline connection of the semi-axle or wear of the teeth of the gears of the differential or main drive. In any case, if the cardan is spinning and the car does not drive, this indicates a rather serious breakdown and, most likely, replacement of the bearing axle shafts or gears will be required.

Oil leakage from the body and from the shank side

The most likely causes of oil leakage from the rear axle housing are:

- wear or damage to the drive gear oil seal;

- axle shaft oil seal wear, determined by oiling of brake shields, drums and pads;

- loosening of the bolts of the rear axle gearbox housing;

- damage to gaskets;

- axial backlash of the shank;

- seizure of the breather.

Wheels are jammed and do not rotate

If the rear wheels are jammed, but the drum and pads are in order, the cause of such a malfunction may be the failure of the bearings or the axle shaft itself. Most likely, in this case, the bearings are crumbled or the semi-axis is deformed (for example, due to impact) and the parts need to be replaced.

A little leaked oil from the bridge through the axle shaft oil seal + dust from the pads = good "glue". Bottom line: shoot the drum and watch. If all the springs are in place, the block has not broken off, then take the sandpaper and clean the drum and pads. Pre-flush them with a carburetor cleaner or similar liquid. Sold in cylinders.

Rear axle repair

Any repair of the rear axle, as a rule, is quite complicated and expensive, so before proceeding with it, you should conduct a thorough diagnosis and make sure that the cause of the vehicle's malfunction lies precisely here. If during the movement of the vehicle there are extraneous noises that were not there before, you should try to determine at what point they appear. If the rear axle makes a hum both under load (when driving with the gearbox engaged) and without it (at neutral speed), then most likely it is not the case. But when the noise is heard only under load, you need to deal with the rear axle.

To repair various components of the rear axle, you will need:

- a set of open-end and spanner wrenches;

- chisel and punch;

- puller for bearings;

- a hammer;

- center punch or simple pencil;

- torque wrench;

- set of probes;

- calipers;

- container for draining the oil.

Shank bearing

The bearing used in the gearbox shank has:

- marking 7807;

- inner diameter — 35mm;

- outer diameter - 73mm;

- width — 27 mm;

- weight - 0,54 kg.

To replace the gearbox shank bearing:

- Prepare a hammer, a flat screwdriver, a chisel, a puller and keys for 17 and 10.

To replace the shank bearing, you will need a hammer, a flat screwdriver, a chisel, wrenches for 17 and 10

To replace the shank bearing, you will need a hammer, a flat screwdriver, a chisel, wrenches for 17 and 10 - Loosen the fixing bracket nut.

To get to the bearing, it is necessary to unscrew the nut of the fixing bracket

To get to the bearing, it is necessary to unscrew the nut of the fixing bracket - Unscrew the fixing bolts of the bearing cover.

After that, unscrew the fixing bolts of the bearing cover

After that, unscrew the fixing bolts of the bearing cover - Remove the cover.

After unscrewing the bolts, you need to remove the bearing cover

After unscrewing the bolts, you need to remove the bearing cover - Remove the adjusting nut.

The next step is to remove the adjusting nut.

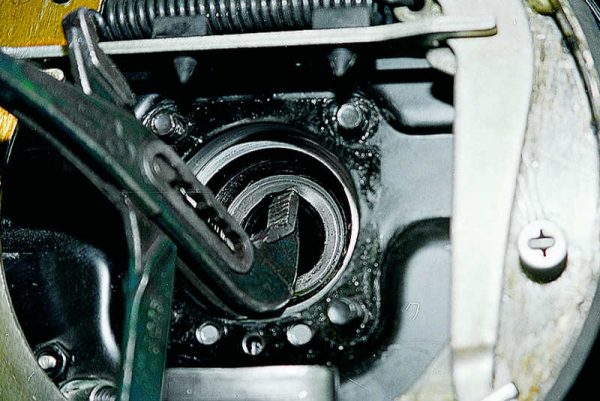

The next step is to remove the adjusting nut. - Carefully tap the bearing from the inside with an impact screwdriver and hammer.

Then you need to carefully knock down the bearing from the inside with an impact screwdriver and a hammer

Then you need to carefully knock down the bearing from the inside with an impact screwdriver and a hammer - Remove the bearing using a puller or a chisel with a hammer.

You can remove the bearing using a puller or a chisel with a hammer.

You can remove the bearing using a puller or a chisel with a hammer.

Installation of a new bearing is carried out in reverse order.

Axle bearing

On the axle shafts of the rear axle VAZ 2107, the bearing 6306 2RS FLT 6306 RS is used, the parameters of which are:

- inner diameter — 30 mm;

- outer diameter - 72 mm;

- width - 19 mm;

- weight - 0,346 kg.

When starting to replace the axle shaft bearing, you should additionally prepare:

- jack;

- supports (for example, logs or bricks);

- wheel stops;

- balloon wrench;

- reverse hammer;

- keys on 8 and 12;

- socket wrench for 17;

- slotted screwdriver;

- the Bulgarian;

- wooden block;

- grease, rags.

To replace a bearing you will need:

- Dismantle the wheel, fixing the machine with wheel stops, loosening the fixing bolts with a wheelbarrow wrench, lifting the body with a jack and substituting supports under it.

You will need to remove the wheel to replace the axle bearing.

You will need to remove the wheel to replace the axle bearing. - Unscrew the guides on the drum with a key of 8 or 12 and remove the drum, applying light blows to it from the inside through a wooden block.

The drum should be knocked down through a wooden block

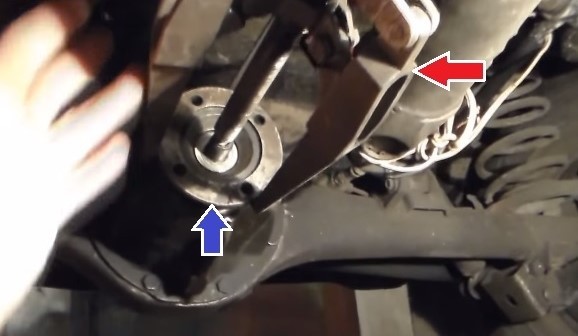

The drum should be knocked down through a wooden block - Unscrew the four fixing bolts of the axle shaft with a 17 socket wrench through the special holes in the flange, while retaining the spring nuts located under the bolts.

The fixing bolts of the axle shaft are unscrewed with a socket wrench by 17

The fixing bolts of the axle shaft are unscrewed with a socket wrench by 17 - Remove the axle shaft with a reverse hammer, which is attached to the flange with wheel bolts.

The axle shaft is removed with a reverse hammer

The axle shaft is removed with a reverse hammer - Remove the O-ring located between the flange and brake shield.

After that, remove the sealing ring between the flange and the brake shield

After that, remove the sealing ring between the flange and the brake shield - Fix the axle shaft (for example, in a vice) and make an incision on the locking ring with a grinder.

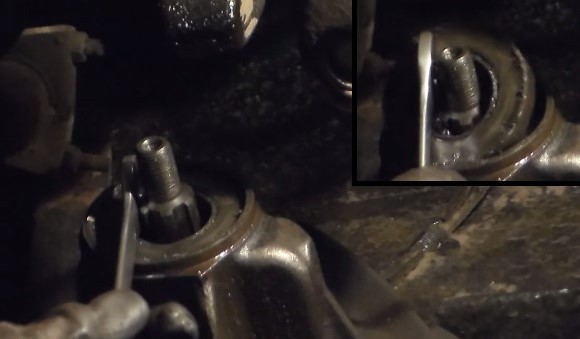

An incision on the locking ring can be made using a grinder

An incision on the locking ring can be made using a grinder - Use a chisel and hammer to knock down the locking ring and bearing. Make sure that the axle shaft is not damaged.

After removing the bearing, make sure that the axle shaft is not damaged.

After removing the bearing, make sure that the axle shaft is not damaged.

After that it is necessary:

- Prepare a new bearing for installation by lubricating it with grease or lithol. Lubrication should also be applied to the axle shaft. Install the bearing in place with a hammer and a piece of pipe.

The new bearing is mounted on the axle shaft with a hammer and a piece of pipe.

The new bearing is mounted on the axle shaft with a hammer and a piece of pipe. - Heat the locking ring with a blowtorch (until a white coating appears) and install it in place with the help of pliers.

- Replace axle shaft seal. To do this, you need to remove the old oil seal from the seat with a screwdriver, remove the old grease from the seat, apply a new one and, using a 32 head, press in a new oil seal (with the spring towards the beam).

A new oil seal can be pressed in with a 32" socket.

A new oil seal can be pressed in with a 32" socket.

Mounting of the axle shaft is carried out in the reverse order. After installing the axle shaft in place, rotate the wheel and make sure that there is no play and extraneous noise during rotation.

Shank gland leak

If an oil leak appears on the gearbox shank, the oil seal will most likely have to be changed. To replace the shank seal, you must:

- Detach the cardan shaft from the shank and take it to the side.

To replace the oil seal, you will need to disconnect the cardan shaft from the gearbox shank

To replace the oil seal, you will need to disconnect the cardan shaft from the gearbox shank - Determine the moment of resistance of the drive gear using a dynamometer or torque wrench.

Drive gear torque can be determined using a dynamometer or torque wrench

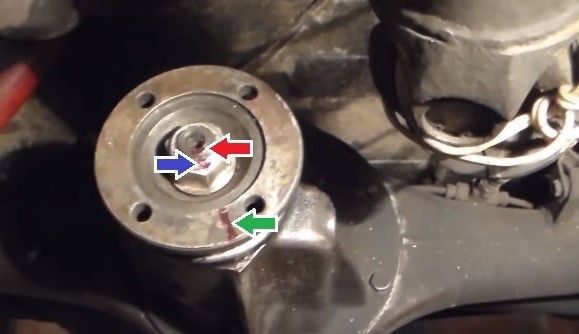

Drive gear torque can be determined using a dynamometer or torque wrench - If there is no dynamometer, marks should be made on the flange and nut with a marker, which should match after assembly.

If there is no dynamometer, marks should be made on the flange and nut with a marker, which must match after assembly

If there is no dynamometer, marks should be made on the flange and nut with a marker, which must match after assembly - Unscrew the central flange fastening nut using a cap head, locking the flange with a special wrench.

The central flange fastening nut is unscrewed using a cap head, locking the flange with a special key

The central flange fastening nut is unscrewed using a cap head, locking the flange with a special key - Using a special puller, remove the flange.

The flange is removed with a special puller

The flange is removed with a special puller - Pry the gland with a screwdriver and remove it from the seat.

Remove the old seal with a screwdriver

Remove the old seal with a screwdriver - Clean the seat of old grease.

The seat should be cleaned of old grease

The seat should be cleaned of old grease - Before installing a new oil seal, lubricate its working surface with lithol.

Before installing a new oil seal, lubricate its working surface with lithol

Before installing a new oil seal, lubricate its working surface with lithol - Using a special cylindrical frame, hammer a new oil seal into place, deepening it by 1,7–2 mm from the end face of the gearbox.

Using a special cylindrical frame, you need to hammer a new oil seal into place, deepening it by 1,7–2 mm from the end of the gearbox

Using a special cylindrical frame, you need to hammer a new oil seal into place, deepening it by 1,7–2 mm from the end of the gearbox - Lubricate the working surface of the stuffing box with new grease.

The working surface of the installed oil seal must be lubricated with new grease.

The working surface of the installed oil seal must be lubricated with new grease. - Reinstall all dismantled parts in reverse order.

Shank play

To measure shank play:

- Go down into the inspection hole and turn the cardan shaft clockwise (or counterclockwise) until it stops.

- In this position, make marks on the flange and on the shaft.

- Turn the shaft all the way in the opposite direction and also make marks. The distance between the first and second marks is the backlash of the shank.

A backlash of 2–3 mm is considered normal.. If the play size approaches 10 mm, measures should be taken to eliminate it. The reason for the increased backlash is the wear of the gear teeth of the main gear and differential, as well as the defect of the bearings, therefore, the side play is eliminated, as a rule, by replacing worn or damaged parts.

In addition to the radial, there may be a longitudinal backlash of the shank, which is also the cause of the hum when the car is moving. If oil has appeared on the neck of the gearbox, this may be the first sign of increased longitudinal (or axial) play. This type of backlash appears, as a rule, due to:

- "Sagging" of the spacer sleeve when tightening the central nut, as a result of which the gear engagement is disrupted, the contact patch is displaced and a hum occurs when the machine moves;

- deformation of the oil flinger ring, made of too soft material.

Underpressed or damaged bearings and worn gears are also causes of end play.

If there are cracks, breaks and other defects on the teeth (or even on one of them) of the main gear gears, this pair must be changed. The main pair is also subject to rejection, upon examination of which one can notice the unevenness of the tooth top band or its narrowing in the middle part. Replacement of the differential box is required in case of "sagging" of its neck, when the bearings enter and exit by hand.

After repair with the replacement of worn and damaged parts, it is important to accurately select the adjusting rings when assembling the shank: at the factory, such rings are installed using a special machine until a minimum noise level is reached. The spacer sleeve is also recommended to be changed every time the gearbox is disassembled. It should be remembered that adjusting the rear axle gearbox requires certain skills, and if this is done for the first time, it is better to have a consultant on hand in the face of an experienced car mechanic.

Video: independently measure the backlash of the shank

We control the oil in the gearbox

For the gearbox of the rear axle of the “seven”, semi-synthetics with viscosity parameters 75W-90 are suitable, for example:

- CASTROL Syntrans Transaxle 75W-90 API GL-4;

- "Lukoil 80W90 GL-5", etc.

1,35 liters of oil is poured through a special filler hole on the gearbox housing. If you need to drain the used oil, a drain hole is provided at the bottom of the gearbox. Before draining the old oil, it is recommended to warm up the car, install it on a flat surface and raise the right side of the car with a jack. If there is metal shavings in the mining, the gearbox tank should be washed with a special liquid or spindle oil.

It is convenient to fill in new oil using a special syringe that can be bought at a car dealership. Both plugs (drain and filler) should be tightened securely, and then check the condition of the breather, which should move freely. If the breather becomes stuck, the container will not contact the atmosphere, which will lead to an increase in internal pressure, damage to the seals and oil leakage. The oil level in the rear axle gearbox is considered normal when the liquid reaches the lower edge of the filler hole.

Video: change the oil in the gearbox yourself

Watch this video on YouTube

Repair and adjustment of the most critical components of the rear axle, as a rule, requires some practice, so it is best to do it under the guidance of an experienced specialist. If extraneous sounds are heard from the side of the rear axle while driving, the cause of their appearance should be established without delay. By ignoring such noises, you can "start" the breakdown and subsequently face a complex and costly repair. Compliance with simple rules for the operation and maintenance of the rear axle will extend the life of the car for many years.