Replacing the wheel bearing Kia Rio 3

Content

- What is the hub bearing responsible for and where is it located?

- How to determine that the hub bearing Kia Rio is defective

- The device and location of the bearing in different generations of Kia Rio

- Choosing a wheel bearing on a Kia Rio

- Instructions for removing the wheel bearing from the Kia Rio

- Installing a new wheel bearing

- How to extend the life of a wheel bearing

Drivers must listen to the operation of the engine. Knocking, buzzing, unusual sounds under the bottom are a sign of possible problems. Often the hub bearing of the Kia Rio 3 causes irritation.

What is the hub bearing responsible for and where is it located?

The wheels are connected to the engine through the axle, they receive torque from it, create the movement of the car. The wheel is attached to the axle with a hub. It also connects the elements: axle and tire. One side is attached to the axle (stud), the other is connected to the wheel. Another disc is connected to the hub - the brake disc. Therefore, it also takes a direct part in braking.

In this connection mechanism, the hub bearing of the Kia Rio 3 is a key element; the operation of cars and safe driving depend on it. If the wheel bearing fails on the Kia Rio 3, the car loses control.

How to determine that the hub bearing Kia Rio is defective

The bearing ensures the rotation of the wheels. There is no replacement program. Masters believe that the Kia Rio 3 wheel bearing can last 100 thousand kilometers. On Russian roads it is impossible. Impacts on the wheels in the wells and shocks are transmitted to the unit; mechanism wears out.

The condition of the bearings is diagnosed when replacing wheels and brake pads or repairing the suspension. Handling is the same whether it's front or rear wheel bearing Kia Rio 3.

The failure of the element is determined by the rumble in the cabin. The higher the speed, the louder the sound. The noise may disappear when the vehicle is turned. If the noise stops during the left maneuver, then the right element has blown away. Vice versa. This is explained by the fact that during any maneuver one side of the car is loaded, the bearing of the other side receives less effort and stops making noise.

The buzzing part is immediately replaced by a new one.

If the Kia Rio 3 wheel bearing jams, an accident is inevitable.

Another problem is that all the parts that connect the wheel to the axle get hot. This is the hub, rim and steering knuckle. A disc brake will follow.

It is easy to verify that the low frequency sound is coming from the bearing. They put the car on a jack, spin a suspicious wheel, wag in horizontal and vertical planes. Squeaking and play between the wheel and axle will indicate a weak link.

The following symptoms indicate a node malfunction:

- A strange noise comes from below.

- Vibrates steering wheel or brake pedal.

- The hub overheats and loses fat.

- Grinding and cleaning of the suspended grinding wheel.

- An unusual sound is made when turning.

- The ABS warning light is on.

- The car is driving sideways.

If you cannot find the source of the strange noise, contact the mechanics of the service station.

Reasons why a knot wears out and breaks:

- Useful life of the vehicle.

- Dirt got into the bearing - the clip is destroyed.

- Worn raceways or balls.

- There is little or no lubrication in the mechanism.

- Extreme driving style.

- Unskilled maintenance of the unit.

- The seal collapsed.

- Worn tie rod end.

- Loose wheel nuts or wheel bolts.

These reasons influence each other. The front wheel bearing of Kia Rio 3 wears out faster in cars.

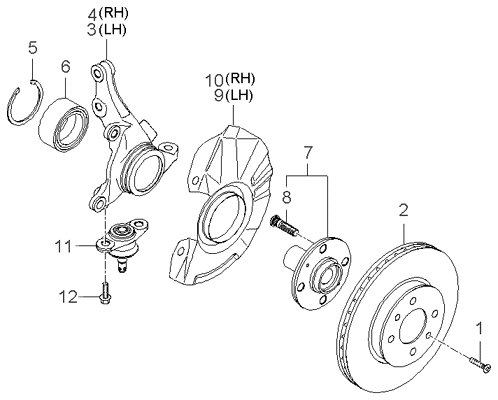

The device and location of the bearing in different generations of Kia Rio

The ball bearing is manufactured using complex technology. It consists of an outer ring and an inner ring. Among them bodies of revolution are balls. The spacer keeps them at the same distance from each other. In annular bodies, the grooves run along the entire diameter. Rollers/balls roll over them.

Bearings cannot be repaired. In case of failure, it is replaced.

In Korean Kia cars after 2012, ball bearings are pressed into the steering knuckle.

When disassembling the mechanism to replace a worn part, the alignment of the wheels is disturbed.

In the first generation, the spacer does not have a rotating part, but two corner roller elements. In this design, you can not do without a sleeve between them.

Choosing a wheel bearing on a Kia Rio

Spare parts are purchased from trusted manufacturers. The low cost is worrisome. Based on the feedback from the owners, a list of manufacturers producing good products for the automotive market has been compiled:

- SNR France. For the second generation cue: a set with a bearing, a retaining ring, a key.

- FAG Germany. For Rio prior to 2011 release Locknut added to kit.

- SCF Sweden. For vehicles after 2012, the lock nut must be purchased separately.

- ROOUVILLE Germany. Complete kit for replacing the wheel bearing Kia Rio 3.

- SNR France. The third generation kit does not include a cotter pin.

Checking a new part. You need to start: if the movement is free, without shocks and noise, then the role is taken.

Counterfeit or low-quality construction poses a threat to the car. Therefore, pay attention to the points:

- Package. Qualitatively, with a good impression, there are QR codes - they buy goods.

- Metal processing. The case is smooth, without scratches and stains - the product will last a long time.

- Price. Too cheap - fake.

- Traces of fat. The manufacturing technology of rotating parts is automated. The amount of lubricant is dosed. Exceeding it in detail is proof of forgery.

The bearing can fall apart and block the wheel at the wrong time, so car owners are left with a spare part.

Instructions for removing the wheel bearing from the Kia Rio

The process is carried out at the service station. But many drivers do it themselves. Replacing the front hub bearing Kia Rio is done in three ways:

- Use an extractor. The hinge with the installed ball bearing is non-removable. In this case, the attenuation of the similarity is not violated. The bad news is that getting to the bearing is difficult.

- The punch is disassembled, the part is changed on the workbench. Use a puller and vise. The advantage of this method is that it is convenient to work with. Minus: the rope broke.

- The rack is completely removed, the knot is replaced by a vise. Long disassembly is a disadvantage of the method, and the advantage is the quality of work.

Tools: a bunch of wrenches, a ratchet, a hammer. You can’t do without a special wheel bearing puller and a 27 head. Instead of a head, a spindle is suitable. In the work you will also need a Phillips screwdriver, a torque wrench. Requires a vise on a workbench. They store engine oil, VD-40 liquid, and rags.

The most commonly practiced second method is to replace the wheel bearing. The work is done in the following order:

- The car is fixed in a stationary state (“handbrake”, the wheels stop).

- The wheel mounts are released, the discs are removed, the brake pedal is pressed (an assistant is required), the hub nut is unscrewed.

- The collar is pulled out and unscrewed from the cuff - fasteners on the back. The released element is tied up, otherwise it will interfere with work.

- Remove the brake disc.

- Make two marks. The first is to look at the offset of the adjusting bolt relative to the rack. The second sign will show how the fist should be placed in relation to the position. So, when assembling, it is necessary to combine signs.

- We unscrew the first support, disconnect it from the rack and the lower ball joint. To do this, unscrew two more bolts.

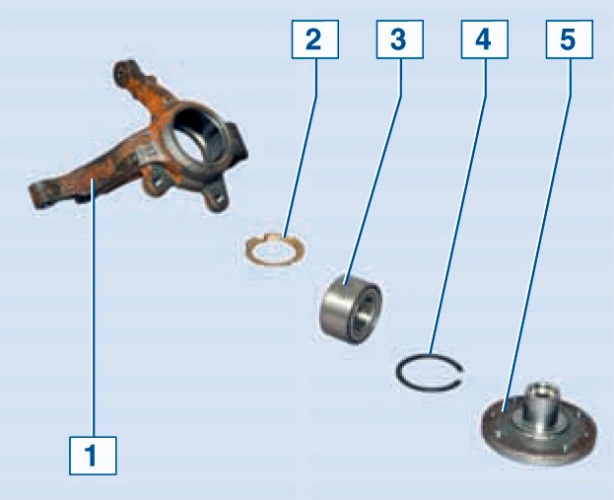

- Remove the ball bearing hub using an appropriately sized adapter. Then the protective ring is turned off.

Now work continues on the workbench.

Installing a new wheel bearing

The moment when the used component is removed and another one is installed is very important. It is important not to deform the parts. Work sequence:

- The extractor is fixed with a vice, the old part is removed.

- The place of the new ball joint on the steering knuckle is cleaned of dirt and lubricated.

- New insert. Use one of two methods: hammerless with a puller or with a chuck.

When you click on a part, all the work is done in reverse order. Replacing the wheel bearing Kia Rio 2 occurs according to the same algorithm.

How to extend the life of a wheel bearing

On the stands, laboratory tests, rotating parts prove 200 km of useful resource. In practice, the mileage is shorter.

This is due to bad roads. City cars that overcome potholes, jump over curbs and arrive at a car service faster. The high-speed guide accelerates the wear of the workpiece. When the parking brake often locks the rear axle, the component is under enormous stress.

Larger discs than those recommended by the manufacturers may cause part wear.

The work of calipers in the brake system is important. When they smoothly stop the rotation of the wheel, the ball joints suffer less.

To prolong the life of the unit, it is necessary to diagnose it more often, drive more carefully, without the need to update the car.