Railway wisdom: how to make sure that diesel does not fail even at minus 50

Half of the length of Russian railways does not involve the use of electric trains. Our wagons are still pulled by a diesel locomotive - a locomotive, which is the direct successor of a steam locomotive, and is equipped with a similar diesel engine that is put on cars. Just a few more. How do Russian Railways workers fight frost, and what size battery should be in order to start a train?

Winter is a tough time not only for cars and their owners. The main roads of the Big Country are still by no means highways, but railways. Eighty-five thousand kilometers, along which hundreds of freight and passenger trains run every day. More than half of this route has not yet been electrified: diesel locomotives serve on such routes, which are often located in areas with difficult weather and climatic conditions. In other words, diesel traction.

The problems of railway engines running on "heavy" fuel are exactly the same as those of ordinary motorists: diesel fuel and oil thicken in the cold, filters become clogged with paraffin. By the way, trains still have a mandatory procedure for changing grease from summer to winter: traction motors, bearings, gearboxes and much more undergo seasonal maintenance. Insulate hoses and pipes of the heating system. They also put special heat mats on the shafts with cooling radiators - this is a separate hello to those who laugh at the cardboard in the radiator grill.

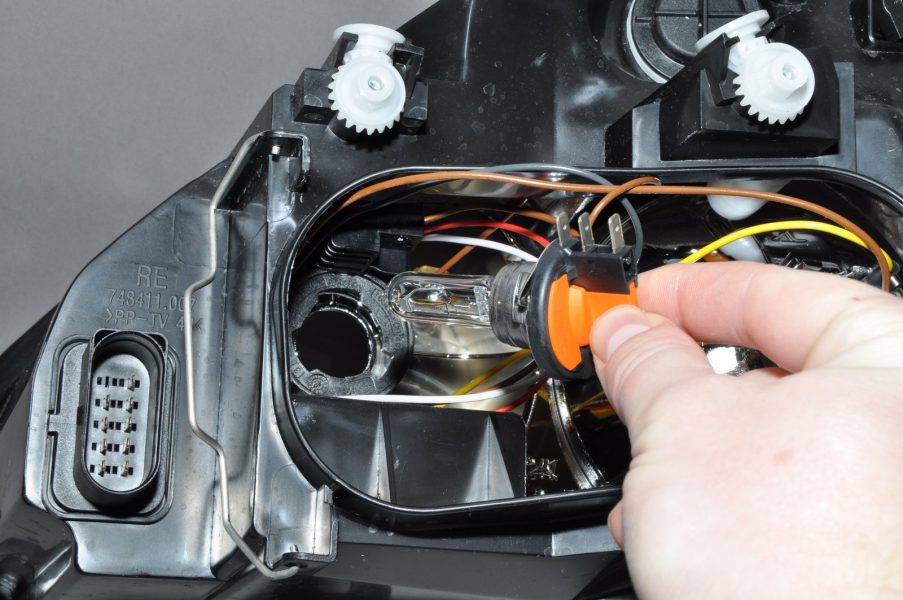

Batteries are not only checked for electrolyte density, but also insulated, which, by the way, can be an interesting solution for motorists in northern latitudes. The battery itself is a lead-acid "battery" with a capacity of 450-550 A / h and weighing about 70 kg!

"Fiery engine", for example, a 16-cylinder V-shaped "diesel", service and prepare for the cold separately. In order for the train to be always ready for the route, despite the frost and cold, in October, a thorough preparation of the trains for the winter begins. When the average daily temperature drops to +15 degrees, heating of the fuel lines is turned on on diesel locomotives, and when the thermometer drops to the average daily mark of +5 degrees, the “hot” time comes.

After all, according to the regulations, the temperature of the oil in the engine should not be lower than 15-20 degrees, depending on the model of the diesel locomotive. The lower the temperature outside, the more often the engine warms up. When the thermometer reaches a scale of -15 degrees, the engine is no longer turned off.

The hosts of “heavy fuel” flying into the pipe do not frighten anyone, because in the cooling system of a diesel locomotive there is not antifreeze or antifreeze, but the most ordinary water. Even in the north, even in winter. Why is that? Yes, because at least a thousand liters of coolant must be poured into a diesel locomotive, but the tightness of all pipes and connections is never at a high level.

Thus, it is possible to calculate the economic component and come to the difficult and expensive idea that it is better not to jam at all. And what quality should antifreeze be in order not to freeze one day, for example, at “minus 46” somewhere at a half-station in Siberia? It’s cheaper, indeed, not to turn off, because the procedure for cooling down the engine is not at all fast and, alas, does not always end in success. And the train must adhere to a strict schedule, despite the cataclysms.