Oil ash content

Content

Oil ash content characterized by two concepts: base oil ash content and sulfate ash content. In short, the usual ash content indicates how well the base base was cleaned, on which the final oil will be made in the future (that is, the presence of various salts and non-combustible, including metallic, impurities in it). As for the sulfate ash content, it characterizes the finished oil, which contains a certain amount of additives, and it indicates precisely their quantity and composition (namely, the presence of sodium, potassium, phosphorus, sulfur and other elements in it).

If the sulfate ash content is high, then this will lead to the formation of an abrasive layer on the walls of the internal combustion engine, and, accordingly, the rapid wear of the motor, that is, a decrease in its resource. The low level of conventional ash content ensures that the exhaust aftertreatment system is protected from contamination. In general, ash content indicators are a rather complicated concept, but interesting, so we will try to put everything in order.

What is ash content and what does it affect

Ash content is an indicator of the amount of non-combustible impurities. In any internal combustion engine, a certain amount of filled oil goes "for waste", that is, it evaporates at high temperature when it enters the cylinders. As a result, combustion products, or simply ash, containing various chemical elements, form on their walls. And it is from the composition of the ash and its quantity that one can judge the notorious ash content of the oil. this indicator affects the ability of carbon deposits to form on internal combustion engine parts, as well as the performance of particulate filters (after all, fireproof soot clogs honeycombs). Therefore, it cannot exceed 2%. Since there are two ash contents, we will consider them in turn.

Base oil ash content

Let's start with the concept of ordinary ash content, as a simpler one. In accordance with the official definition, ash content is a measure of the amount of inorganic impurities remaining from the combustion of a sample of oil, which is expressed as a percentage of the mass of the oil being tested. This concept is usually used to characterize oils without additives (including base oils), as well as various lubricating fluids that are not used in internal combustion engines or in machine technology in general. usually, the value of the total ash content is in the range from 0,002% to 0,4%. Accordingly, the lower this indicator, the cleaner the tested oil.

What influences ash content? Normal (or basic) ash content affects the quality of oil purification, which also does not contain additives. And since they are currently present in almost all used motor oils, the concept of ordinary ash content is not widely used, but instead the concept of sulfate ash content is used in a broad sense. let's move on to it.

Sulphated ash

Impurities in oil

So, sulfate ash content (another name for the level or indicator of sulfate slags) is an indicator for determining additives that include organic metal compounds (namely, their constituent salts of zinc, potassium, magnesium, calcium, barium, sodium and other elements ). When oil with such additives is burned, ash is formed. Naturally, the more of them there are in the oil, the more ash there will be. It, in turn, mixes with resinous deposits in the internal combustion engine (this is especially true if the internal combustion engine is old and / or the oil has not been changed in it for a long time), as a result of which an abrasive layer is formed on rubbing parts. During operation, they scratch and wear out the surface, thereby reducing the resource of the internal combustion engine.

Sulphated ash content is also expressed as a percentage of the oil weight. However, to determine it, it is necessary to carry out a special procedure with burning and calcining the test mass. And the percentage is taken from the solid balance. At the same time, sulfuric acid is used in the work in order to isolate sulfates from the mass. This is where the name sulfate ash comes from.. We will consider the exact algorithm for performing measurements according to GOST below.

Effect of sulfate ash content

Now let's move on to the question of what does sulfate ash affect. But before that, it must be clarified that its concept is directly related to the concept of the base number of engine oil. This value allows you to set the amount of carbon deposits in the combustion chamber. Usually oil gets there through the piston rings, flowing down the walls of the cylinders. The amount of said ash directly affects the functioning of the ignition system, as well as the start of the internal combustion engine in the cold season.

The dependence of the base number on time

So, sulfate ash content is directly proportional to the initial value of the base number of also unused (or only filled) oil. At the same time, it must be understood that the base number is not an absolute indicator of the neutralizing ability of a lubricating fluid, and over time it falls. This is due to the presence of sulfur and other harmful components in the fuel. And the poorer the fuel (the more sulfur in it), the faster the base number falls.

Please note that sulfate ash content directly affects the flash point of engine oil, namely, over time, as the additives in its composition burn out, the value of the mentioned temperature decreases. It also reduces the performance of the oil itself, no matter how high quality it is.

The use of low-ash oils has "two sides of the coin". On the one hand, their use is justified, since such compounds are designed to prevent rapid pollution of exhaust systems (namely, equipped with catalysts, particulate filters, EGR systems). On the other hand, low-ash oils do not provide (reduce) the required level of protection for internal combustion engine parts. And here, when choosing an oil, you need to make a choice of the “golden mean” and be guided by the recommendations of the car manufacturer. That is, look at the value of ash content and alkaline number!

The role of sulfur in the formation of ash

Please note that the normal ash content of motor oils has nothing to do with the level of sulfur in them. That is, low-ash oils will not necessarily be low-sulfur, and this issue needs to be clarified separately. It is worth adding that sulfate ash content also affects pollution and the operation of the particulate filter (the possibility of regeneration). Phosphorus, on the other hand, gradually disables the catalyst for afterburning carbon monoxide, as well as unburned hydrocarbons.

As for sulfur, it disrupts the operation of the nitrogen oxide neutralizer. Unfortunately, the quality of fuel in Europe and in the post-Soviet space is very different, not to our advantage. namely, there is a lot of sulfur in our fuel, which is very harmful for internal combustion engines because, when mixed with water at high temperatures, it forms harmful acids (mainly sulfuric), which corrode the internal combustion engine parts. Therefore, it is better for the Russian market to choose an oil with a high base number. And as mentioned above, in oils where there is a high alkaline number, there is a high ash content. At the same time, it must be understood that there is no universal oil, and it must be selected in accordance with the fuel used and the features of the internal combustion engine. First of all, you need to build on the recommendations of the car manufacturer (namely, its internal combustion engine).

What is the requirement for the ash content of oil

Ash from oil burnout

The low ash content of modern oils is dictated by the environmental requirements of Euro-4, Euro-5 (obsolete) and Euro-6, which are valid in Europe. In accordance with them, modern oils should not greatly clog particulate filters and car catalysts, and release a minimum of harmful substances into the environment. they are also designed to minimize soot deposits on valves and cylinders. However, in reality, this approach sharply reduces the resource of modern internal combustion engines, but it is also beneficial for car manufacturers, as it directly leads to frequent replacement of a car by car owners in Europe (consumer demand).

As for domestic motorists (although this applies more to domestic fuel), in most cases, low-ash oils will adversely affect liners, fingers, and also contribute to scuffing skirts in the internal combustion engine. However, with a low ash content of oils, the amount of deposits on the piston rings will be less.

Interestingly, the level of sulfate ash content in American oils (standards) is lower than in European ones. This is due to the use of high-quality base oils belonging to group 3 and / or 4 (made on the basis of polyalphaolefins or using hydrocracking technology).

Catalyst cells clogged with soot

A few words about the internal combustion engines of new models, in which the cylinder blocks are made of aluminum with an additional coating (many modern cars from the VAG concern and some “Japanese”). On the Internet, they write a lot about the fact that such motors are afraid of sulfur, and this is true. However, in engine oil, the amount of this element is much less than in fuel. Therefore, first of all, it is recommended to use gasoline standard Euro-4 and higherand also use low-sulphur oils. But, remember that low-sulfur oil is not always low-ash oil! So always check the ash content in a separate documentation that describes the typical characteristics of a particular engine oil.

Production of low-ash oils

the need for the manufacture of low-ash oils arose largely due to environmental requirements (the notorious Euro-x standards). In the manufacture of motor oils, they contain (in different quantities, depending on many things) sulfur, phosphorus and ash (it becomes sulfate later). So, the use of the following chemical compounds leads to the appearance of the mentioned elements in the composition of oils:

- zinc dialkyldithiophosphate (the so-called multifunctional additive with antioxidant, antiwear and extreme pressure properties);

- calcium sulfonate is a detergent, that is, a detergent additive.

Based on this, manufacturers have found several solutions to reduce the ash content of oils. So, the following are currently in use:

- the introduction of detergent additives not into the oil, but into the fuel;

- use of ashless high-temperature antioxidants;

- the use of ashless dialkyldithiophosphates;

- the use of low-ash magnesium sulfonates (however, in limited quantities, since this also contributes to the formation of deposits in the internal combustion engine), as well as detergent alkylphenol additives;

- the use of synthetic components in the composition of oils (for example, esters and thickening additives resistant to degradation, necessary to ensure the desired viscosity-temperature characteristics and low volatility, namely, base oils from 4 or 5 groups).

Modern chemical technologies make it possible to easily obtain oil with any ash content. You just need to choose the composition that is best suited for a particular car.

Ash level standards

The next important question is to determine ash content standards. It is worth mentioning right away that they will depend not only on the type of internal combustion engine (for gasoline, diesel internal combustion engines, as well as internal combustion engines with gas-balloon equipment (GBO), these indicators will differ), but also on the current environmental standards (Euro-4, Euro-5 and Euro-6). In most base oils (that is, before the introduction of special additives into their composition), the ash content is insignificant, and is approximately 0,005%. And after the addition of additives, that is, the manufacture of ready-made motor oil, this value can reach the rook 2% that GOST allows.

The ash content standards for motor oils are clearly stated in the standards of the European Association of Auto Manufacturers ACEA, and deviations from them are unacceptable, therefore all modern (licensed) motor oil manufacturers are always guided by these documents. We present the data in the form of a table for the currently widespread environmental standard Euro-5, which combines the values of chemical additives and individual existing standards.

| API Requirements | SL | SM | SN-RC/ILSAC GF-5 | CJ-4 |

|---|---|---|---|---|

| The phosphorus content,% | 0,1 max | 0,06-0,08 | 0,06-0,08 | 0,12 max |

| Sulfur content, % | - | 0,5-0,7 | 0,5-0,6 | 0,4 max |

| Sulphated ash, % | - | - | - | 1 max |

| ACEA requirements for gasoline engines | C1-10 | C2-10 | C3-10 | C4-10 |

| - | LowSAPS | MidSAPS | MidSAPS | LowSAPS |

| The phosphorus content,% | 0,05 max | 0,09 max | 0,07-0,09max | 0,09 max |

| Sulfur content, % | 0,2 max | 0,3 max | 0,3 max | 0,2 max |

| Sulphated ash, % | 0,5 max | 0,8 max | 0,8 max | 0,5 max |

| Base number, mg KOH/g | - | - | 6 min | 6 min |

| ACEA requirements for commercial diesel engines | E4-08 | E6-08 | E7-08 | E9-08 |

| The phosphorus content,% | - | 0,08 max | - | 0,12 max |

| Sulfur content, % | - | 0,3 max | - | 0,4 max |

| Sulphated ash, % | 2 max | 1 max | 1 max | 2 max |

| Base number, mg KOH/g | 12 min | 7 min | 9 min | 7 min |

As can be seen from the table above, it is difficult to judge ash content according to the American API standard, and this is due to the fact that ash content is not so scrupulous in the New World. namely, they simply indicate which oils are in canisters - full, medium ash (MidSAPS). As such, they do not have low-ash. Therefore, when choosing one or another oil, you need to focus primarily on the ACEA marking.

For example, based on the information provided in accordance with the Euro-5 standard, which is valid and relevant in 2018 on the territory of the Russian Federation, for a modern gasoline car it is allowed to fill in C3 oil according to ACEA (usually SN according to API) - the content of sulfate ash is no more than 0,8% (medium ash). If we talk about diesel engines operating in difficult conditions, then for example, the ACEA E4 standard does not allow exceeding 2% of the sulphated ash content in the fuel.

Ash content requirements for LPG vehicles

As for cars with gas-cylinder equipment, it is better for them to use low ash oils. This is due to the chemical composition of gasoline and gas (no matter methane, propane or butane). There are more solid particles and harmful elements in gasoline, and in order not to spoil the entire system, special low-ash oils must be used. Lubricant manufacturers specifically offer consumers so-called “gas” oils designed for the corresponding ICE.

However, their significant drawback is their high cost, and in order to save money, you can simply look at the characteristics and tolerances of conventional “gasoline” oils and select the appropriate low-ash composition. And remember that you need to change such oils according to the specified regulations, despite the fact that the transparency of mining will be much higher than that of traditional oils!

Method for determining the ash content

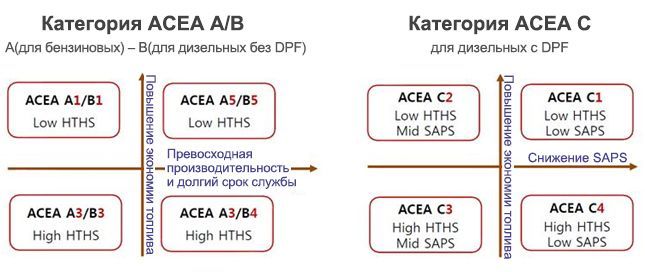

But how is the ash content of engine oil determined and how to understand with what ash content the oil in the canister? It is easiest for the consumer to determine the ash content of engine oil simply by the designations on the container label. On them, the ash content is usually indicated according to the ACEA standard (European standard for car manufacturers). In accordance with it, all currently sold oils are divided into:

- full ash. They have a complete package of additives. In English, they have the designation - Full SAPS. According to the ACEA standard, they are designated by the following letters - A1 / B1, A3 / B3, A3 / B4, A5 / B5. Ash impurities here are about 1 ... 1,1% of the total mass of the lubricating fluid.

- medium ash. They have a reduced package of additives. Referred to as Middle SAPS or Mid SAPS. According to ACEA they are designated C2, C3. Similarly, in medium ash oils, the ash mass will be about 0,6 ... 0,9%.

- Low Ash. The minimum content of metal-containing additives. Designated Low SAPS. According to ACEA they are designated C1, C4. For low-ash, the corresponding value will be less than 0,5%.

Please note that in some cases, oils with ACEA designations from C1 to C5 are combined into one group called “low ash”. namely, such information can be found in Wikipedia. However, this is not entirely correct, since such an approach simply indicates that all these lubricants are compatible with catalytic converters, and nothing more! In fact, the correct gradation of oils by ash content is given above.

.

Ash standards

Testing different oil samples

There is a Russian interstate standard GOST 12417-94 “Petroleum products. Method for determining sulfate ash, according to which anyone can measure the sulfate ash content of the oil being tested, since this does not require complex equipment and reagents. There are also other, including international, standards for determining the ash content, namely, ISO 3987-80, ISO 6245, ASTM D482, DIN 51 575.

First of all, it should be pointed out that GOST 12417-94 defines sulfate ash content as a residue after carbonization of a sample, treated with sulfuric acid and calcined to constant weight. The essence of the verification method is quite simple. At its first stage, a certain mass of the tested oil is taken and burned to a carbonaceous residue. then you need to wait for the resulting residue to cool, and treat it with concentrated sulfuric acid. further ignite at a temperature of +775 degrees Celsius (a deviation of 25 degrees in one direction and the other is allowed) until the carbon is completely oxidized. The resulting ash is given some time to cool down. After that, it is treated with dilute (in equal volumes with water) sulfuric acid and calcined at the same temperature until its mass value becomes constant.

Under the influence of sulfuric acid, the resulting ash will be sulfate, from where, in fact, its definition came from. then compare the mass of the resulting ash and the initial mass of the tested oil (the mass of ash is divided by the mass of the burnt oil). The mass ratio is expressed as a percentage (that is, the resulting quotient is multiplied by 100). This will be the desired value of sulfate ash content.

As for the usual (basic) ash content, there is also a state standard GOST 1461-75 for it called “Oil and oil products. Method for determining the ash content”, in accordance with which the test oil is checked for the presence of various harmful impurities in it. Due to the fact that it involves complex procedures, and even more so for various applications, we will not present its essence in this material. If desired, this GOST can be easily found on the Internet.

There is also one Russian GOST 12337-84 "Motor oils for diesel engines" (last edition of 21.05.2018/XNUMX/XNUMX). It clearly spells out the values of various parameters for motor oils, including domestic ones used in diesel ICEs of various capacities. It indicates the allowable values of various chemical components, including the amount of allowable soot deposits.