Volkswagen BUD engine

Content

VAG engineers designed and put into production a power unit that replaced the well-known BCA. The motor has replenished the line of VAG engines EA111-1,4, including AEX, AKQ, AXP, BBY, BCA, CGGB and CGGA.

Description

The VW BUD engine was developed for popular Volkswagen Golf, Polo, Caddy, Skoda Octavia and Fabia models.

Released since June 2006. In 2010, it was discontinued and replaced by a more modern CGGA power unit.

The Volkswagen BUD engine is a 1,4-liter gasoline in-line four-cylinder aspirated engine with a capacity of 80 hp. with and a torque of 132 Nm.

Installed on cars:

- Volkswagen Golf 5 /1K1/ (2006-2008);

- Golf 6 Variant /AJ5/;

- Pole 4 (2006-2009);

- Golf Plus /5M1/ (2006-2010);

- Caddy III /2KB/ (2006-2010);

- Skoda Fabia I (2006-2007);

- Octavia II /A5/ (2006-2010).

The cylinder block is made of high strength aluminum alloy.

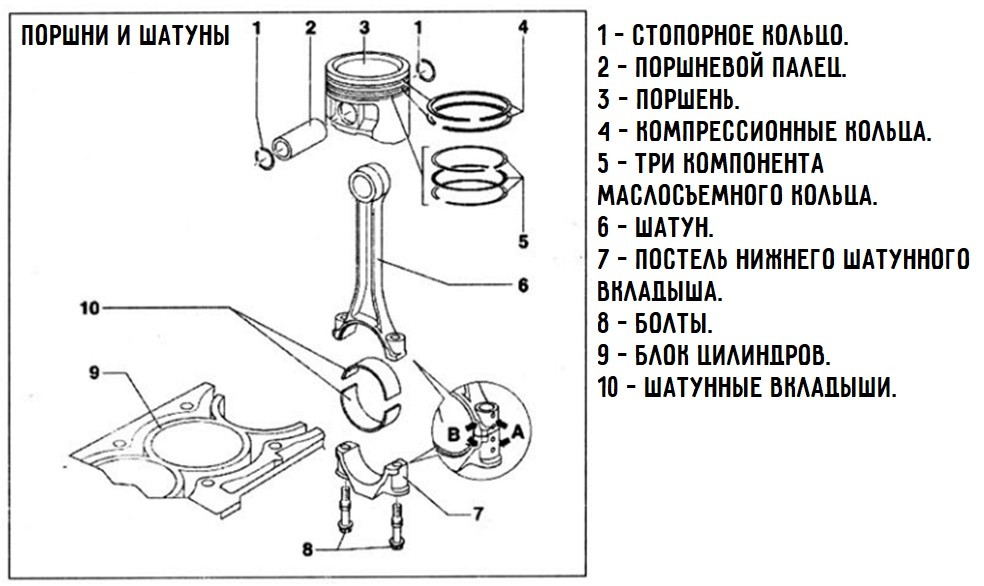

Aluminum pistons, made according to the standard scheme - with three rings. The top two are compression, the bottom is oil scraper. Piston pin of floating type, from axial displacement is fixed by retaining rings. A feature of the design of the oil scraper rings is that they are three-component.

The crankshaft is located on five bearings, it has an unpleasant feature for car owners. When repairing the motor, the crankshaft must not be removed, since deformation of the beds of the main bearings of the cylinder block occurs.

Thus, it is impossible to replace even the main liners, including in a car service. By the way, car owners on the forums focus on the fact that the root bearings are not for sale. If necessary, the shaft is changed in assembly with the cylinder block.

Aluminum cylinder head. On top are two camshafts and 16 valves (DOHC). The need to adjust their thermal gap manually has disappeared, it is automatically adjusted by hydraulic compensators.

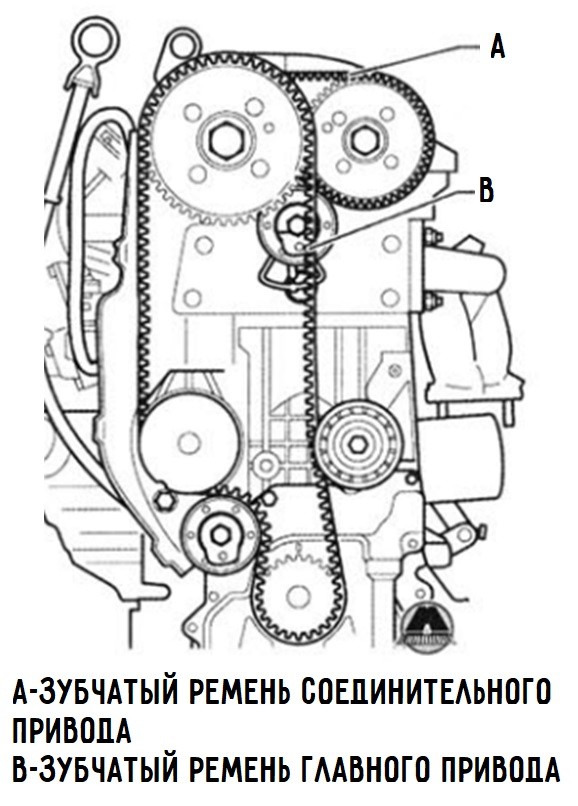

The timing drive consists of two belts.

The main (large) transmits rotation to the intake camshaft. Further, the auxiliary (small) rotates the exhaust shaft. Car owners note a short service life of belts.

The manufacturer recommends replacing them after 90 thousand kilometers, then carefully inspect them every 30 thousand kilometers.

But the experience of using an internal combustion engine with a two-belt timing drive shows that the auxiliary belt rarely withstands 30 thousand km, so it has to be replaced at the recommended time in advance.

Fuel supply system of injection type, injection and ignition - Magneti Marelli 4HV. ECU with self-diagnosis function. Applied gasoline AI-95. High voltage coils are individual for each cylinder. Spark plugs VAG 101 905 617 C or 101 905 601 F.

Combined type lubrication system. The oil pump is gear-driven, driven by the toe of the crankshaft. The recommended oil is synthetics with a tolerance of 502 00/505 00 with a viscosity of 5W30, 5W40 or 0W30.

According to the majority of car owners, the BUD engine turned out to be successful.

The advantage of the considered internal combustion engine lies in its simple design and high efficiency.

Technical specifications

| Manufacturer | car concern VAG |

| Release year | 2006 |

| Volume, cm³ | 1390 |

| Power, hp from | 80 |

| Torque, Nm | 132 |

| Compression ratio | 10.5 |

| Cylinder block | aluminum |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 76.5 |

| The piston stroke, mm | 75.6 |

| Timing drive | belt |

| Number of valves per cylinder | 4 (DOHC) |

| Turbocharging | no |

| Hydraulic compensators | Yes |

| Camshaft adjuster | no |

| Lubrication system capacity, l | 3.2 |

| Applied oil | 5W-30 |

| Oil consumption, l/1000 km | 0.5 |

| Fuel system | injector, port injection |

| Fuel | gasoline AI-95 |

| Environmental standards | Euro 4 |

| Resource, outside. km | 250 |

| Location | transverse |

| Tuning (potential), l. With | 115* |

*without resource reduction up to 100 l. With

Reliability, weaknesses, maintainability

Reliability

The main factors determining the reliability of the engine are its resource and safety margin.

The manufacturer determined the mileage before overhaul at 250 thousand km. In practice, with proper maintenance and reasonable operation, the capabilities of the unit increase significantly.

Igor 1 spoke lucidly on this topic: “... the engine, if desired, can also be killed, somehow: on a cold start from 4-5 thousand revolutions ... and if the car is not treated as scrap metal, then it will not become one. And the capital, I think, will not come before 500 thousand km».

Car service workers note that they had to meet cars with a mileage of more than 400 thousand km. At the same time, the CPG did not have excessive wear.

It was not possible to find specific figures on the margin of safety. The fact is that both the manufacturer and car owners who have tried to tune the internal combustion engine to increase power do not recommend doing this.

A simple flashing of the ECU without mechanical intervention will give an increase in power by 15-20 hp. With. Further forcing the motor does not bring noticeable changes.

Additionally, tuning enthusiasts need to remember that any intervention in the design of the motor causes a decrease in the resource and changes the characteristics of the unit in the direction of their deterioration. For example, the degree of exhaust purification will decrease, at best, to Euro 2 standards.

Weak spots

Despite the fact that, in general, BUD is considered quite reliable, designers could not avoid weaknesses.

The timing drive is considered more dangerous than weak. The problem is that when the belt breaks or jumps, bending of the valves is inevitable.

Along the way, the piston is destroyed, cracks may appear not only in the cylinder head, but also in the cylinder block itself. In any case, the unit will have to be overhauled or replaced.

The next engineering miscalculation is the unfinished design of the oil receiver. He often clogs up. As a result, engine oil starvation may occur.

The throttle assembly and the USR valve are also prone to rapid contamination. In this case, the problem leads to floating motor speed. The culprits of the malfunction are poor-quality fuel and lubricants and not timely maintenance of the internal combustion engine. Flushing fixes the problem.

At specialized forums, motorists raise the issue of failure of ignition coils. The only way out of this situation is to replace them.

The rest of the malfunctions are not typical, they do not occur in every engine.

Maintainability

The VW BUD engine has a high maintainability. This is facilitated by the simplicity of the design and the absence of problems with finding the necessary spare parts for restoration.

The only trouble for car owners is the aluminum cylinder block, which is considered to be disposable.

At the same time, some malfunctions in the unit can be eliminated. For example, weld an external crack, or, if necessary, cut a new thread.

To restore the motor, original components and parts are used. Their counterparts do not always meet the quality requirements. Some motorists use parts purchased on the secondary market (dismantling) for repairs. It is not worth doing this, since the residual resource of such spare parts cannot be determined.

Experienced car owners repair the unit in a garage. Subject to the technology of restoration work and a thorough knowledge of the motor structure, this practice is justified. Those who decide to take on serious repairs for the first time on their own need to be prepared for a lot of nuances.

For example, due to the dense arrangement of assemblies and lines during repairs, it is necessary to ensure that during assembly all wires, hoses and pipelines are laid strictly in the place where they were previously placed.

At the same time, attention should be paid to the absence of their contact with moving and heating mechanisms and parts. Failure to comply with these parameters will result in the impossibility of assembling the engine.

Watch this video on YouTube

It is important to observe the tightening torques of all threaded connections. Failure to comply with the manufacturer's requirements in this matter, in the worst case, will lead to failure of the mating parts due to an elementary thread break, at best, to the appearance of a leak at the junction.

During the operation of the internal combustion engine, such deviations are not permissible.

It seems that everything is simple, but for many, the violation of these simple technological conditions ends with the next repair, only at a car service. Naturally, with additional material costs.

Based on the complexity of the repair, it is sometimes advisable to consider the option of purchasing a contract engine. Often, such a solution to the issue will be cheaper than carrying out a major overhaul in full.

A contract ICE will cost 40-60 thousand rubles, while a complete overhaul will not cost less than 70 thousand rubles.

The Volkswagen BUD engine is reliable and durable with timely and high-quality service. At the same time, it is considered quite economical in its class.