Volkswagen BWK engine

Content

The next 1,4 TSI engine designed by VAG engineers cannot be called successful. A number of engine performance parameters turned out to be slightly lower than expected.

Description

The power unit with the BWK code has been assembled at the Volkswagen plant since September 2007. Its main purpose was to equip new Tiguan models, on which it was installed until July 2018.

The saturation of the engine with advanced technologies did not leave without attention not only ordinary motorists, but also technical experts of various levels.

Unfortunately, operating experience has revealed a number of significant shortcomings, due to which the motor has not received wide recognition, especially in the Russian Federation.

The unit turned out to be very demanding on the rules of operation, the quality of fuels and lubricants, consumables, qualified maintenance and the timing of its implementation. It is clear that such requirements for our car owner in full for a number of reasons are not feasible.

Structurally, the engine is a modified version of BMY with increased power.

BWK is an in-line four-cylinder petrol unit with dual supercharging. Its volume is 1,4 liters, the power is 150 liters. s and a torque of 240 Nm.

Cast iron cylinder block. The sleeves are bored out in the body of the block.

Pistons are standard, made of aluminum, with three rings. Two upper compression, lower oil scraper.

Crankshaft steel, forged, conical shape. Mounted on five pillars.

Aluminum cylinder head. On the upper surface is a bed with two camshafts. Inside - 16 valves (DOHC), equipped with hydraulic lifters. The intake camshaft has a camshaft adjuster.

Timing chain drive. It differs in that it has a number of design flaws (see Chap. Weaknesses).

Fuel supply system - injector, direct injection. A distinctive feature is demanding on the quality of gasoline. Poor quality fuel causes detonation, which destroys the pistons. In parallel, there is the formation of soot on the valves and spray nozzles. The phenomena of loss of compression and burnout of the pistons become inevitable.

injection/ignition. The unit is controlled by the Motronic MED 17 (-J623-) control unit with self-diagnosis function. Ignition coils are individual for each cylinder.

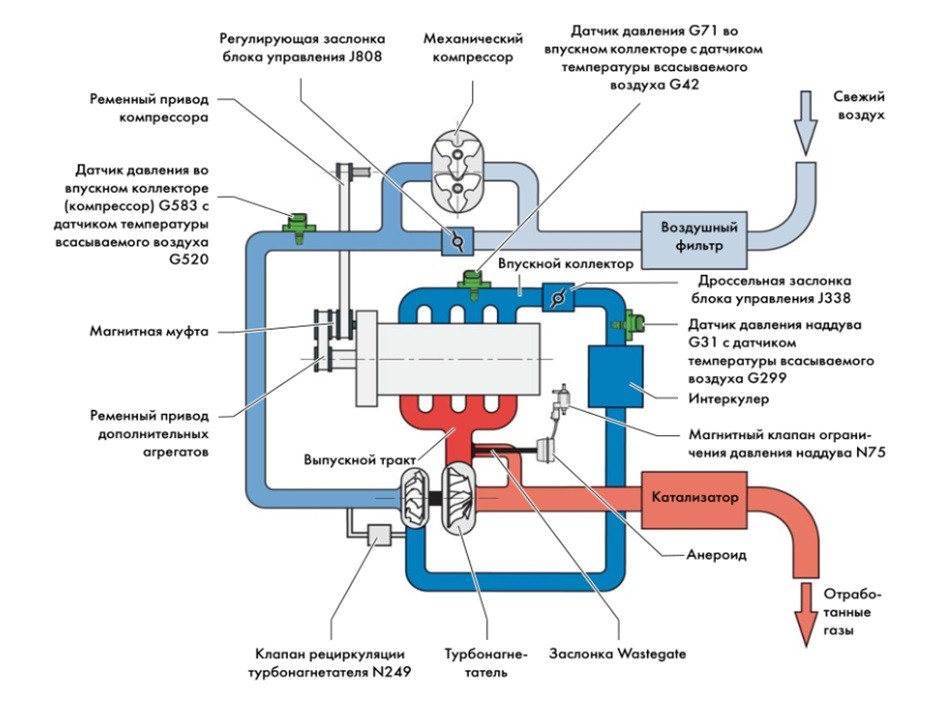

Supercharging feature. Up to 2400 rpm it is carried out by an Eaton TVS mechanical compressor, then the KKK K03 turbine takes over. If more torque is required, the compressor is automatically activated again.

Such a tandem completely eliminates the effect of turbo-lag and provides good traction on the bottoms.

Combined lubrication system. Oil VAG Special G 5W-40 (approvals and specifications: VW 502 00 / 505 00). System capacity 3,6 liters.

The manufacturer has repeatedly improved the internal combustion engine, but the desired result for the Russian market has not been achieved.

Technical specifications

| Manufacturer | Mlada Boleslav Plant (Czech Republic) |

| Release year | 2007 |

| Volume, cm³ | 1390 |

| Power, hp from | 150 |

| Power index, l. s/1 liter volume | 108 |

| Torque, Nm | 240 |

| Compression ratio | 10 |

| Cylinder block | cast iron |

| Number of cylinders | 4 |

| Cylinder head | aluminum |

| Fuel injection order | 1-3-4-2 |

| Cylinder diameter, mm | 76.5 |

| The piston stroke, mm | 75.6 |

| Timing drive | chain |

| Number of valves per cylinder | 4 (DOHC) |

| Turbocharging | KKK K03 turbine and Eaton TVS compressor |

| Hydraulic compensators | Yes |

| Camshaft adjuster | yes (inlet) |

| Lubrication system capacity, l | 3.6 |

| Applied oil | VAG Special G 5W-40 |

| Oil consumption (calculated), l / 1000 km | up to 0,5* |

| Fuel system | injector, direct injection |

| Fuel | gasoline AI-98** |

| Environmental standards | Euro 4 |

| Resource, outside. km | 240 |

| Weight, kg | ≈126 |

| Location | transverse |

| Tuning (potential), l. With | up to 230*** |

* on a serviceable engine, no more than 0,1 l, ** AI-95 can be used, *** up to 200 l. with no loss of resource

Reliability, weaknesses, maintainability

Reliability

The Volkswagen BWK engine, according to the manufacturer's intention, should become the most technologically advanced in its class. Unfortunately, in reality he showed the most capricious.

Particularly pronounced were vibrations, stretching of the timing chain, a problematic piston group, progressive oil and coolant smudges, and a number of others. On specialized forums, you can read a lot of negative statements from car owners about this motor. For example, SeRuS from Moscow directly writes: “… CAVA replaced the mega problematic BWK».

At the same time, for many, the considered ICE causes positive emotions. Feedback from wowo4ka (Lipetsk): “... I work at a company where the life of two such cars flowed before my eyes (we are talking about Tiguan). On one, during the sale, there was a mileage of 212 thousand, on the second 165 thousand km. On both machines, the engines were still alive. And this is without intervention in the motor. So, this motor is not so bad !!!».

Or the statement of TS136 (Voronezh): “... I don’t understand at all what problems there can be with the repeatedly recognized best engine in Europe !!! Tiguan 2008, BWK, ran 150000 km on it - nothing broke at all. Everything works fine, I do not add oil at all».

The resource and margin of safety are the main components of the reliability of the internal combustion engine. There are no questions in this regard. The manufacturer claims a repair-free run of 240 thousand km. The possibility of forcing the engine is also impressive. A simple flashing of the ECU (Stage 1) increases the power to 200 hp. With. Deeper tuning will allow you to shoot 230 hp. With.

Despite this, the engine cannot be called reliable due to its "painful" reaction to low-quality gasoline and deviations from the manufacturer's requirements in terms of maintenance.

Weak spots

There are a lot of weak points in the engine under consideration. Of these, the most problematic is the timing drive.

Operating experience has shown that the chain brings the most trouble. The real resource before its replacement is 80 thousand km. At the same time, the crankshaft sprocket and the valve timing regulator must be changed. Moreover, this is in addition to the repair kit for the chain itself (tensioner parts, sprockets, etc.).

The unsuccessful design of the hydraulic tensioner (there is no blocking of the counter-movement of its plunger) has led to the fact that in the absence of pressure in the motor lubrication system, the chain tension is weakened. This leads to a jump and ends with the impact of the valves on the pistons.

The result is always deplorable - the failure of the parts of the CPG and the valve mechanism. To avoid breakdowns, it is recommended not to start the car from a tow and not leave it in gear for long periods of parking (especially on a slope).

High demands on fuel quality. Eases in this matter lead to detonation, burnout and destruction of the pistons.

Poor-quality oil leads to the formation of coke deposits on the valves and the exhaust tract, oil receiver. This is most apparent with an aggressive driving style.

With long service life, an engine oil burn is observed. Decoking the oil scraper rings and replacing the valve stem seals temporarily eliminate this problem.

Coolant loss is often observed. It is not always possible to detect a malfunction in time. The fact is that there are no obvious leaks of liquid, and small portions from seepage have time to evaporate. And only later, in the wake of the scale formed, it is possible to determine the exact location of the leak. Usually the problem should be looked for in the intercooler.

Often the engine troit during a cold start, the sound is similar to the operation of a diesel engine. Unpleasant, but not dangerous. This is the normal mode of operation of the unit. After warming up everything goes back to normal.

The turbine drive is not reliable. Thorough cleaning eliminates the problem.

There are other malfunctions on the engine, but they are not of a massive nature.

Maintainability

Given the high manufacturability of the motor, it is easy to conclude that it is maintainable. Repairable, but in a car service. Additionally, you need to be prepared for the high cost of restoration.

The cast-iron block of cylinders allows complete overhaul. Finding parts is no problem.

Those who carried out the restoration of the internal combustion engine are advised to purchase a contract engine. In terms of costs, this option will be cheaper. The cost of a contract engine lies in the range of 80-120 thousand rubles.

You can see the repair process by watching the video:

The Volkswagen BWK engine, for all its advantages, is not popular among Russian car owners, it is considered capricious and not reliable.