How to Clean a Soldering Iron - Complete Guide

Content

- Signs for cleaning

- What is causing the problem?

- Why do they need maintenance?

- Cleaning methods

- Video

- How to prevent oxidation?

- Tips for keeping your soldering iron tip in good condition

- What happens if you don't service your soldering iron?

- Benefits of proper soldering iron care

- Common problems that occur when the soldering iron is not properly maintained

- Time to change tip

- Conclusion

There is nothing worse than a soldering iron that does not solder.

Today we will discuss how to clean a soldering iron and a few tips for keeping it in good condition.

You'll see three easy ways to clean your soldering iron tip so it looks like you just bought it.

Signs for cleaning

- Does not work properly

When a soldering iron does not work properly, it is often because the tip is not clean. If the tip is dirty, the solder will not stick to it and the connection will be weak.

- Takes a long time to warm up

If you notice that your soldering iron heats up for a long time, then its oxidized part does not allow it to give off heat. In this case, the corroded part acts as an insulator.

It's like trying to get through a pet doorway.

Here you can find out how long the soldering iron heats up.

- Stinks when turned on

When the soldering iron starts to work, it immediately begins to heat the tip. If it then starts to stink, the heat burns the dirty part at the top. This means that oxidation has begun to form at the tip.

What is causing the problem?

There are many reasons to cause oxidation. This condition is caused by the use of low-quality solder wire or contact paste containing various metals that stick to the tip of the soldering iron.

Using a soldering iron at high temperatures will damage the tip.

Also, the soldering iron rusts over time due to the fact that it has not been cleaned for a long time.

Why do they need maintenance?

The main reason soldering irons need maintenance is that they can get dirty. If the iron is not cleaned regularly, dirt and grime will begin to accumulate, which will eventually affect the quality of your solder joints.

Another reason you should service your soldering iron is that it can affect the life of the tool. It can break down if you don't regularly clean and tin the soldering iron. This will shorten the life of the soldering iron and may cause it to break.

Cleaning methods

The combination of sponge and metal wool effectively cleans the tip of the soldering iron. In addition, the use of flux and a rotating tool can help restore the original shiny look.

wet sponge

A wet sponge this is the cheapest and worst way. Before and after working with a soldering iron, you need to walk a couple of times with a damp sponge.

This will remove the coarse layers of dirt, but the oxidation will remain. A damp sponge may help at first, but over time, this is not the best option.

Sponge is a good free option.

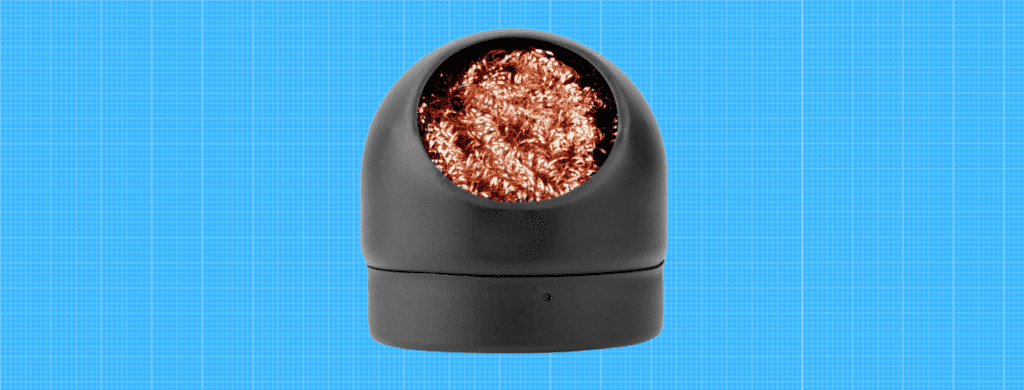

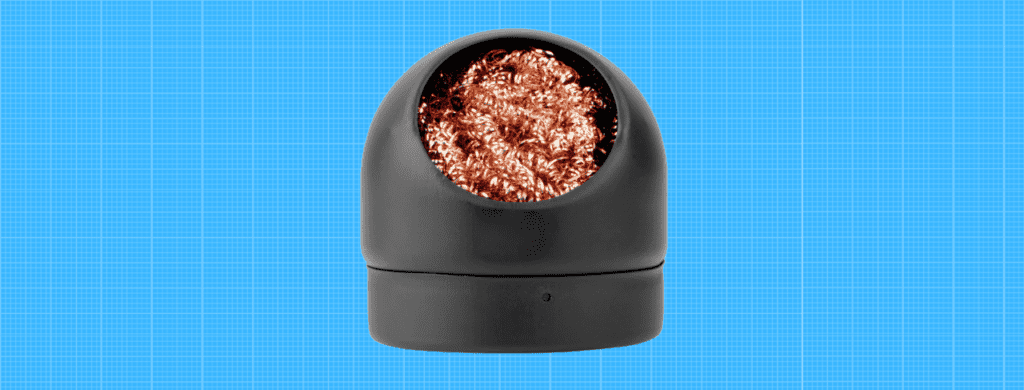

steel wool

steel wool This is a handy tool for cleaning the soldering iron tip. To clean the tip, simply take a piece of steel wool and rub it over the tip until the solder is gone.

Before putting away the soldering iron, be sure to remove any debris that may have remained.

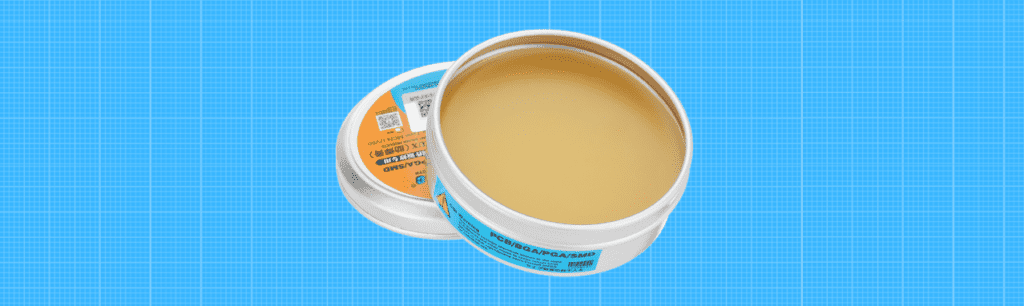

Flow

Take flow or contact paste and dip a hot soldering iron in them. This will remove both dirt and some of the oxidized part. This method is taught in school.

This is good, but again not enough to remove the corroded part.

Because there are minor metals in the flux and contact paste that will stick to your soldering iron again. When the soldering iron cools down, the oxidized part will reappear after a while.

Always use high quality tip flux.

rotary tool

Definitely the best way to recover a doppelgänger is when you just bought a soldering iron. Is to use rotating cleaning tool.

Here is the secret. We will first remove the layer of dirt and oxidation with some of these extensions.

Before cleaning and polishing, the soldering iron must be cool and dry in order to successfully remove all contaminants and oxidize parts.

First, carefully go over each part of the soldering iron tip. Usually you need a minute or two to remove the details. Do not press, but lightly press on the top next to the top.

Now that you've removed the dirt and oxidized metal stuck to your soldering iron, use one of these polishing tips. This will return the soldering iron to its original appearance. Expand each part in detail. You won't need more than a minute of work.

The Rotary tool is inexpensive and it does such a good job. My honest recommendation: even if you are a beginner or advanced, grab this tool because it will make your job easier when it comes time to service your soldering iron.

Video

In this video, we will show you how to clean the countertop and return it to its former shiny appearance.

How to prevent oxidation?

Tinning your advice

tinning The tip of a soldering iron means covering it with a thin layer of solder. This will help the solder flow more efficiently and also protect the tip from oxidation. To tin a soldering iron tip, simply apply a small amount of solder to the tip and wipe it with a clean cloth.

The solder will help keep the tip clean and will also make it easier to apply the solder to the joint. Be sure to tin the soldering iron tip before each use.

When you're done using the soldering iron, be sure to tin the tip again.

Storing tips canned will double tip life.

Tips for keeping your soldering iron tip in good condition

- Regular cleaning

Regular cleaning is the main way to save your soldering iron. After working with the soldering iron, take a few minutes to clean it.

- Storage Tips

Keeping in a dry place is a must. The tip of the soldering iron is metal, like any other. That is why it must be in a dry place so that it does not rust.

If the soldering iron is in a basement or damp room, place it in a box to prevent direct contact with humid air. Covering with a cloth may also help.

- Quality solder

A quality coil and flux will slow down the corrosion of your soldering iron. A cheap coil is made of poor quality material that clings to the soldering iron rather than the part.

- Optimal temperature

The optimum temperature for a soldering iron is around 600-650°F (316-343°C). Suppose the temperature of the soldering iron is too low. In this case, the solder will not flow properly and the connection will be weak. If the temperature is too high, the solder may melt prematurely or damage the components being joined.

Maintaining the optimum temperature will help prolong the life of your soldering tip.

What happens if you don't service your soldering iron?

If you don't maintain your soldering iron, it may eventually stop working. The main problems you will face are corrosion, rust and the accumulation of dirt and soot.

Benefits of proper soldering iron care

Proper care of your soldering iron has several benefits. These include:

- Extended soldering iron life

- Better soldering

- Less chance of damage to the soldering iron or soldered components

Common problems that occur when the soldering iron is not properly maintained

If you don't maintain your soldering iron, there are a few common problems that can occur. These include:

- Soldering iron does not heat up well

- Solder will not flow correctly

- The solder joint will be weak and can break easily.

- The soldering iron may start to rust or rust

- Dirt and dirt can accumulate on the tip of the soldering iron and other parts of the tool. This will make proper soldering difficult and may damage the soldering iron.

Time to change tip

Soldering iron tips corrode quickly and cannot last forever. Regular cleaning can extend the shelf life. But when you notice that small holes start to form at the top, it's time to replace.

Small holes are formed after corrosion. They are like a metal disease. They destroy the metal at the micro level and thus create irregularly shaped holes. After a couple of months, if you clean the soldering iron, the sting begins to corrode and makes holes in itself.

Then it's too late to start cleaning, but you can try. Damage over time will result in less and less heat transfer, and the soldering iron will become unusable.

That's why it's good to have spare tips for your soldering tool. It is important to know that not every soldering iron has additional tips. Usually cheaper soldering irons don't have spare tips.

Temperature controlled soldering irons showed better wear resistance than soldering irons without temperature control.

Conclusion

Today, all tips are made of metal. Metal is a material that is subject to rapid rusting. That is why it needs to be maintained frequently.

Don't let your soldering iron get dirty after work. If possible, get spare tips so you don't end up in a situation where you need a soldering iron that won't fit.

And don't forget to tin the tip when you're done.