How to check the USR

Content

Checking the system comes down to identifying the performance of the EGR valve, its sensor, as well as other components of the crankcase ventilation system (Exhaust Gas Recirculation). To check, a motorist will need an electronic multimeter capable of operating in ohmmeter and voltmeter mode, a vacuum pump, an ECU error scanner. exactly how to check the egr will depend on the particular element of the system. The simplest test for operability can be the usual visual control of operation when power is applied to it or air is discharged.

What is the EGR system

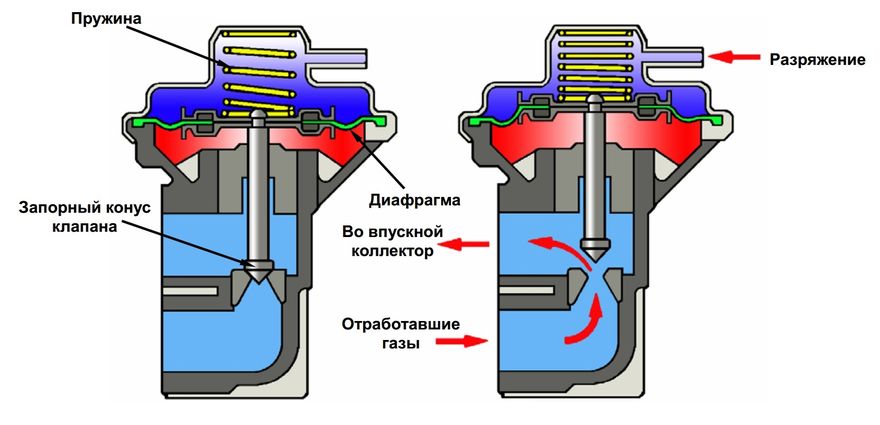

in order to understand the description of the USR health check, it is worth briefly dwelling on what kind of system it is, why it is needed and how it works. So, the task of the EGR system is to reduce the level of formation of nitrogen oxides in the exhaust gases. It is installed on both gasoline and diesel engines, with the exception of those equipped with a turbocharger (although there are exceptions). Limiting the production of nitrogen oxides is achieved due to the fact that part of the exhaust gases is sent back to the internal combustion engine for afterburning. Because of this, the temperature of the combustion chamber decreases, the exhaust becomes less toxic, detonation decreases as a higher ignition timing is used and fuel consumption is reduced.

The first EGR systems were pneumomechanical and complied with EURO2 and EURO3 environmental standards. With the tightening of environmental standards, almost all EGR systems have become electronic. One of the basic components of the system is the USR valve, which also includes a sensor that controls the position of the specified valve. The electronic control unit controls the operation of the pneumatic valve using the control electro-pneumatic valve. so, checking the USR comes down to finding out the operability of the USR valve, its sensor, as well as the control system (ECU).

Signs of breakage

There are a number of external signs indicating that there is a problem with the system, namely the EGR sensor. However, the signs below may indicate other breakdowns in the internal combustion engine, so additional diagnostics are needed both for the system as a whole and for the valve in particular. In the general case, the symptoms of a non-working EGR valve will be the following signs:

- Reducing the power of the internal combustion engine and the loss of the dynamic characteristics of the car. That is, the car "does not pull" when driving uphill and in a loaded state, and also accelerates poorly from a standstill.

- Unstable operation of the internal combustion engine, "floating" speed, especially at idle. If the motor is running at low speeds, it may suddenly stop.

- ICE stalls shortly after starting. Occurs when the valve is stuck open and the exhaust gases go to the intake in full.

- Increased fuel consumption. This is caused by a decrease in the vacuum in the intake manifold, and as a result, the re-enrichment of the air-fuel mixture.

- Error generation. Often, the “check engine” warning light is activated on the dashboard, and after performing diagnostics with scanning devices, you can find errors related to the operation of the USR system, for example, error p0404, p0401, p1406 and others.

If at least one of the listed signs appears, it is worth immediately diagnosing using an error scanner, it will make sure that the problem is in the USR valve. For example, Scan Tool Pro Black Edition makes it possible to read errors, view the performance of various sensors in real time and even adjust some parameters.

With this scanner, you can see how the solenoid valve of the vacuum regulator works (details at the end of the article). Having such a device, you can quickly find out the cause and begin to eliminate it. Checking the valve in a garage is quite simple.

Causes of malfunctions of the EGR system

There are only two basic causes of malfunctions of the USR valve and the system as a whole - too little exhaust gases pass through the system and too much exhaust gases pass through the system. In turn, the reasons for this may be the following phenomena:

- On the EGR valve stem carbon deposits form. This happens for natural reasons. As mentioned above, exhaust gases pass through it, and soot settles on the valve walls, including the stem. This phenomenon is especially aggravated in conditions when the machine operates in aggressive conditions. namely, with the wear of the internal combustion engine, an increase in the amount of crankcase gases, the use of low-quality fuel. After diagnosing a valve, it is always recommended to clean the stem with a carb cleaner or similar degreasing cleaner. Often, some solvents (for example, white spirit) or pure pure acetone are used for this. you can also use gasoline or diesel fuel.

- Diaphragm leakage EGR valve. This breakdown leads to the fact that the said valve does not fully open and does not close, that is, exhaust gases leak through it, which leads to the consequences described above.

- Channels of the EGR system are coked. This also results in exhaust gases and air not being blown through them normally. Coking occurs due to the appearance of soot on the walls of the valve and / or channels through which the exhaust gases pass.

- The EGR system was incorrectly muffled. Some car owners who regularly encounter the fact that due to the use of the designated ICE system loses power, they simply turn off the EGR valve. However, if such a decision has been made, then this must be done correctly, otherwise the air mass meter will receive information that a very large air flow is occurring. This is especially true when buying a used car, when the new owner does not know that the EGR valve is plugged on the car. If the car is equipped with such a system, then it is advisable to ask the former car owner about its condition, and also ask if the USR system was completely muffled.

- EGR valve jamming during its closing and/or opening. There are two options here. The first is the sensor itself is faulty, which cannot transmit correct data to the electronic control unit. The second is problems with the valve itself. It either doesn't open completely or doesn't close completely. This is usually due to a large amount of soot on it, formed as a result of the combustion of fuel.

- EGR valve jerky. A working solenoid should provide a smooth reversal of the stem, and accordingly, the sensor should capture smoothly changing data on the position of the damper. If the transition occurs abruptly, then the corresponding information is transmitted to the computer, and the system itself does not work correctly with the consequences described above for the internal combustion engine.

- On those vehicles where valve movement is provided stepper electric drive, the possible reasons lie precisely in it. namely, the electric motor may fail (for example, short-circuit the winding, fail the bearing), or the drive gear may fail (one or more teeth on it break or completely wear out).

USR system check

Naturally, on different makes and models of cars, the location of the EGR sensor will be different, however, be that as it may, this assembly will be in close proximity to the intake manifold. Less commonly, it is located in the suction tract or on the throttle block.

In garage conditions, the check should begin with a visual inspection. By and large, there are two methods for diagnosing the EGR valve - with and without its dismantling. However, it is still better to perform a more detailed check with the dismantling of the assembly, since after the check, if the valve is clogged with deposits of burnt fuel, it can be cleaned before being reinstalled. To begin with, we will consider methods for checking without dismantling individual parts.

How to check the operation of the EGR

Before doing a full check, you need to make sure that the valve works at all. Such a check is done elementarily.

When it is necessary to check the serviceability of the pneumatic valve, it is enough to observe the stroke of the stem during gas passes (one person revs, the second looks). Or by pressing the membrane - the speed should sag. in order to check the EGR solenoid valve, you need to apply power directly from the battery to the plus and minus of the connector, while listening for any clicks. Having done these steps, you can proceed to a more detailed check of the EGR.

Pressing the valve

With the internal combustion engine running at idle, you need to slightly press on the membrane. Depending on the specific structure of the valve, it can be located in various places. For example, in the popular car Daewoo Lanos, you need to press under the plate, under it there are cutouts in the body, through which you can press on the membrane. That is, pressing occurs not on the membrane itself, since it is protected by the body, but on that part of the body that is located just above it.

If, in the process of pressing the specified node, the engine speed dipped and it began to “choke” (the speed began to fall), this means that the valve seat is in good condition, and by and large, nothing needs to be repaired, except for preventive purposes ( to do this, it will be necessary to dismantle the EGR valve and in parallel to carry out additional complex diagnostics of the unit). However, if nothing happens after the specified pressing, and the internal combustion engine does not lose speed, then this means that the membrane is no longer tight, that is, the EGR system practically does not work. Accordingly, it is necessary to dismantle the USR valve and carry out additional diagnostics of the state of both the valve itself and other elements of the system.

Valve check

As mentioned above, the location of the valve may vary in different cars, however, often it is installed in the intake manifold area. For example, on a Ford Escape 3.0 V6 car, it is installed on a metal pipe coming from the intake manifold. The valve opens due to the vacuum that comes from the solenoid. An example of further verification will be given precisely on the internal combustion engine of the specified vehicle.

In order to check the efficiency of the EGR valve, it is enough to disconnect the hose from the valve at idle speed of the internal combustion engine, through which vacuum (vacuum) is supplied. If there is a vacuum pump in the nominal accessibility, then you can connect it to the valve hole and create a vacuum. If the valve is working, the internal combustion engine will begin to "choke" and twitch, that is, its speed will begin to fall. Instead of a vacuum pump, you can simply connect another hose and create a vacuum simply by sucking in air with your mouth. The consequences should be the same. If the internal combustion engine continues to operate normally, then the valve is most likely faulty. It is advisable to dismantle it to perform a detailed diagnosis. Be that as it may, its further repair will need to be carried out not at its seat, but in the conditions of a car repair shop (garage).

Check the solenoid

A solenoid is an electrical resistance that allows current to flow through it. The solenoid changes the voltage passing through it using pulse-width modulation (PWM). The voltage changes during operation, and this is a signal to apply vacuum to the EGR valve. The first thing to do when checking the solenoid is to make sure that the vacuum has a good enough vacuum. We give an example of verification for the same Ford Escape 3.0 V6 car.

The first thing to do is to disconnect the small tubes at the bottom of the solenoid, after which you need to start the internal combustion engine. Please note that the tubes must be removed carefully so as not to break the fittings to which they fit! If the vacuum on one of the tubes is in order, then it will be audible, in extreme cases, you can put your finger on the tube. If there is no vacuum, additional diagnostics are necessary. To do this, it will also be necessary to further dismantle the USR valve from its seat for further comprehensive diagnostics.

After that, it is necessary to check the electrical part, namely, it is necessary to check the power supply of the solenoid. To do this, you need to detach the chip from the specified element. There are three wires - signal, power and ground. Using a multimeter switched to DC voltage measurement mode, you need to check the power. Here one probe of the multimeter is placed on the supply contact, the second - on the ground. If there is power, the multimeter will show the value of the supply voltage of about 12 volts. At the same time, it is worth checking the integrity of the impulse wire. This can also be done using a multimeter, but switched to the "dialing" mode. On the specified Ford Escape 3.0 V6 it has purple insulation, and at the ECU input it has the number 47 and also purple insulation. Ideally, all wires should be intact and with intact insulation. If the wires are broken, then they must be replaced with new ones. If the insulation is damaged, then you can try to insulate it with electrical tape or heat shrink tape. However, this option is only suitable if the damage is minor.

After that, you need to check the integrity of the wiring of the solenoid itself. To do this, you can switch the multimeter to the continuity mode or measure electrical resistance. then, with two probes, respectively, connect to the two outputs of the solenoid wiring. The resistance value for different devices may be different, but Be that as it may, it must be different from zero and from infinity. Otherwise, there is a short circuit or a winding break, respectively.

Checking the EGR sensor

The function of the sensor is to record the pressure difference in one and the other part of the valve, respectively, it simply transmits information to the computer about the position of the valve - is it open or closed. First of all, you need to check the presence of power on it.

Switch the multimeter to DC voltage measurement mode. Connect one of the probes to wire No. 3 on the sensor, and the second probe to ground. next you need to start the engine. If everything is normal, then the voltage between the two indicated probes should be equal to 5 volts.

next you need to check the voltage on the impulse wire No. 1. In a state when the internal combustion engine is not warmed up (the EGR system is not working), the voltage on it should be about 0,9 Volts. You can measure it in the same way as the power wire. If a vacuum pump is available, then a vacuum can be applied to the valve. If the sensor is working, and it will fix this fact, then the output voltage on the impulse wire will gradually increase. At a voltage of approximately 10 volts, the valve should open. If during the test the voltage does not change or changes non-linearly, then, most likely, the sensor is out of order and it is necessary to carry out its additional diagnostics.

If the car stalls after a short engine operation, then you can unscrew the USR valve and leaning it and removing it again to look at the reaction of the internal combustion engine - if you remove the valve from the crankcase, a lot of smoke comes out and the internal combustion engine starts to work more evenly, the ventilation system or the valve itself is faulty. Additional checks are needed here.

Disassembly check

It is best to check the EGR valve when it is removed. This will make it possible to visually and with the help of instruments assess its condition. The first thing to do is to check if it works. In fact, the valve is a solenoid (coil), which must be supplied with 12 volts of direct current, as in the electrical circuit of a car.

Please note that the design of the valves may differ, and accordingly, the numbers of contacts that need to be energized will also be different, respectively, there is no universal solution here. For example, for a Volkswagen Golf 4 APE 1,4 car, there are three pins on the valve with numbers 2; four; 4. Voltage must be applied to terminals numbered 6 and 2.

It is advisable to have an AC voltage source on hand, since in practice (in a car) the control voltage varies. So, in the normal state, the valve begins to open at 10 volts. If you remove 12 volts, then it will automatically close (the stem will go inside). Along with this, it is worth checking the electrical resistance of the sensor (potentiometer). With a working sensor on the open valve, the resistance between pins 2 and 6 should be about 4 kOhm, and between 4 and 6 - 1,7 kOhm. In the closed position of the valve, the corresponding resistance between pins 2 and 6 will be 1,4 kOhm, and between 4 and 6 - 3,2 kOhm. For other cars, of course, the values will be different, but the logic will remain the same.

Along with checking the performance of the solenoid, it is worth checking the technical condition of the valve. As mentioned above, soot (products of combustion of fuel) accumulates on its surface over time, settling on its walls and on the rod. Because of this, the smooth movement of the valve and stem may be impaired. Even if there is not a lot of soot there, it is still recommended for preventive purposes to clean it inside and out with a cleaner.

Software verification

One of the most complete and convenient methods for diagnosing the EGR system is to use software installed on a laptop (tablet or other gadget). So, for cars manufactured by the VAG concern, one of the most popular diagnostic programs is VCDS or in Russian - “Vasya Diagnostic”. Let's take a quick look at the EGR testing algorithm with this software.

EGR check in the Vasya Diagnost program

The first step is to connect the laptop to the ICE electronic control unit and run the appropriate program. then you need to enter a group called "ICE Electronics" and the menu "Custom Groups". Among others, at the very bottom of the channel list, there are two channels numbered 343 and 344. The first one is called “EGR Vacuum Regulator Solenoid Valve; actuation" and the second is "EGR Solenoid Valve; actual value".

In practice, this means that according to channel 343, one can judge at what relative value the ECU decides to open or close the EGR valve in theory. And channel 344 shows at what actual values the valve operates. Ideally, the difference between these indicators in dynamics should be minimal. Accordingly, if there is a significant discrepancy between the values in the two indicated channels, then the valve is partially out of order. And the greater the difference in the corresponding readings, the more damaged the valve. The reasons for this are the same - a dirty valve, the membrane does not hold, and so on. Accordingly, using software tools, it is possible to assess the condition of the EGR valve without dismantling it from its seat on the internal combustion engine.

Hack and predictor Aviator

Checking the EGR system is not particularly difficult, and even a novice motorist can do it. If the valve fails for some reason, the first thing to do is to scan the ECU memory for errors. it is also advisable to dismantle and clean it. If the sensor is out of order, it is not repaired, but replaced with a new one.