How to check and repair the rear axle VAZ 2101 with your own hands

Content

- Bridge VAZ 2101

- Rear axle device

- Malfunctions of the rear axle VAZ 2101 and their symptoms

- How to check the rear axle

- Repair of the rear axle VAZ 2101

- Rear axle oil

Absolutely all representatives of the domestic "classics" have rear-wheel drive. Whoever says anything, but it has a number of advantages regarding handling, acceleration and even safety. However, these advantages will be useful to the driver only when the rear axle is fully operational, because even the smallest breakdown of one of its many parts can cause a malfunction of the entire mechanism.

Bridge VAZ 2101

The rear axle is one of the main elements of the VAZ 2101 transmission. It is designed to transmit torque from the cardan shaft to the axle shafts of the machine, as well as to evenly distribute the load on the wheels while driving.

Technical specifications

The drive axles of VAZ vehicles of the 2101-2107 series are unified. Their design and characteristics are completely identical, with the exception of the gear ratio. In the "penny" it is 4,3. VAZ models with a station wagon body (2102, 2104) were equipped with gearboxes with a gear ratio of 4,44.

Table: main characteristics of the rear axle VAZ 2101

| Name | Index |

| Factory catalog number | 21010 – 240101001 Feet |

| Length, mm | 1400 |

| Case diameter, mm | 220 |

| Stocking diameter, mm | 100 |

| Weight without wheels and oil, kg | 52 |

| Transfer type | Hypoid |

| Gear ratio value | 4,3 |

| Required amount of lubricant in the crankcase, cm3 | 1,3 – 1,5 Feet |

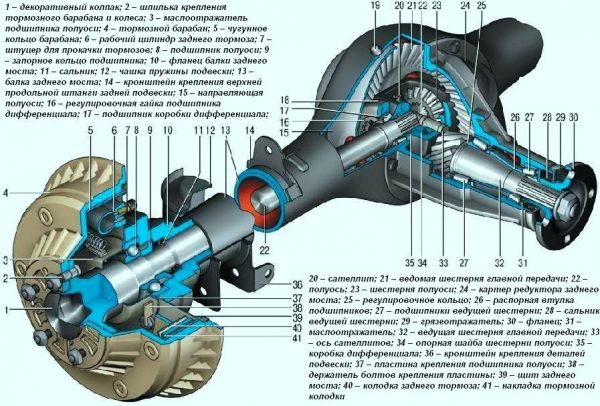

Rear axle device

The design of the rear axle VAZ 2101 consists of two main elements: a beam and a gearbox. These two nodes are combined into one mechanism, but at the same time they perform different functions.

What is a beam

The beam is a structure of two stockings (casings) rigidly connected by welding. Flanges are welded into the ends of each of them, designed to accommodate semi-axial seals and bearings. The ends of the flanges have four holes for installing brake shields, oil deflectors and plates pressing the bearings.

The middle part of the rear beam has an extension in which the gearbox is located. In front of this extension there is an opening closed by a crankcase.

Half-shafts

The axle shafts of the machine are installed in stockings. At the inner ends of each of them there are splines, with the help of which they are connected to the side gears of the gearbox. Their uniform rotation is ensured by ball bearings. The outer ends are equipped with flanges for attaching brake drums and rear wheels.

Reducer

The design of the gearbox consists of the main gear and the differential. The role of the device is to evenly distribute and redirect the force from the driveshaft to the axle shafts.

main gear

The main gear mechanism includes two conical gears: driving and driven. They are equipped with helical teeth that ensure their connection at a right angle. Such a connection is called hypoid. This design of the final drive can significantly improve the process of grinding and running in of gears. In addition, maximum noiselessness is achieved during operation of the gearbox.

The gears of the main gear VAZ 2101 have a certain number of teeth. The leading one has 10 of them, and the driven one has 43. The ratio of the number of their teeth determines the gear ratio of the gearbox (43:10 \u4,3d XNUMX).

The driving and driven gears are selected in pairs on special machines in the factory. For this reason, they are also on sale in pairs. In the case of repair of the gearbox, the replacement of gears is allowed only as a set.

Differential

The center differential is necessary to ensure the rotation of the wheels of the machine with different speeds depending on the load on them. The rear wheels of a car, while turning or overcoming obstacles in the form of pits, potholes, ledges, pass an unequal distance. And if they were rigidly connected to the gearbox, this would lead to constant slippage, causing rapid tire wear, additional stress on transmission parts, and loss of contact with the road surface. These problems are solved with the help of a differential. It makes the wheels independent of each other, thereby allowing the car to freely enter a turn or overcome various obstacles.

The differential consists of two side gears, two satellite gears, shims and a cast iron box that acts as a housing. The half shafts enter with their splines into the side gears. The latter rest on the inner surfaces of the box with the help of shims having a certain thickness. Between themselves, they do not contact directly, but through satellites that do not have a rigid fixation inside the box. During the movement of the car, they move freely around their axis, but are limited by the surface of the driven gear, which prevents the axis of the satellites from moving out of their seats.

The differential housing with the mechanism is installed inside the gearbox on roller bearings pressed onto the housing journals.

Malfunctions of the rear axle VAZ 2101 and their symptoms

The complexity of the design of the rear axle does not affect either its performance or service life. If all the details are matched exactly, the unit systematically undergoes appropriate maintenance, and the car has not been involved in traffic accidents, it may not declare itself at all. But the opposite also happens. If you do not pay due attention to the bridge and ignore the possible signs of its malfunction, problems will definitely appear.

Signs of failure of the rear axle "penny"

The most likely symptoms that a vehicle's axle is bad are:

- oil leakage from the gearbox or axle shafts;

- lack of transmission of torque from the "cardan" to the wheels;

- increased noise level in the rear lower part of the car;

- perceptible vibration in motion;

- uncharacteristic noise (hum, crackling) during the acceleration of the car, as well as during engine braking;

- knocking, crackling from the side of the bridge when entering a turn;

- crunch at the beginning of the movement.

Damage to the rear axle VAZ 2101

Consider the listed signs in the context of possible malfunctions.

Oil leak

Let's start with the simplest - grease leaks. This is probably the most common problem that owners of "penny" face. A timely detected leak does not pose any threat to the assembly, however, if the oil level reaches a critical minimum, rapid wear of the final drive gears, axle shafts and stellites is inevitable.

Grease from the rear axle of the “penny” can leak from under:

- breather, which serves as a kind of pressure valve;

- oil fill plugs;

- drain plug;

- shank oil seal;

- reducer flange gaskets;

- half shaft seals.

Lack of transmission of torque from the propeller shaft to the wheels

Unfortunately, such a malfunction is also not uncommon. Most often, it occurs due to the poor quality of parts or their factory defects. The breakdown is characterized by the lack of reaction of one or both rear wheels with a normally twisting “cardan”. If you have to face such a situation, you can safely prepare to replace the axle shaft. Most likely, she simply burst.

Increased noise level in the area of the bridge

Strong noise from the bridge while driving can indicate malfunctions such as:

- loosening of the fastening of the rims to the axle shafts;

- wear of splines of semiaxes;

- failure of semi-axial bearings.

Vibration

Vibration in the rear of the vehicle during its movement can be caused by deformation of the shaft of one or both axle shafts. Similar symptoms also occur due to beam deformation.

Noise when accelerating or braking

A hum or crackle that occurs when the machine accelerates, as well as during engine braking, is usually a sign of:

- insufficient amount of lubricant in the gearbox;

- wear of the bearings of the mechanism or their incorrect tightening;

- failure of semi-axial bearings;

- development or incorrect adjustment of the distance between the gears of the final drive.

Knock or crackle when turning

Extraneous sounds in the region of the rear axle during cornering may occur due to:

- the occurrence of chips and scuffs on the surface of the axis of the satellites;

- wear or damage to the satellites;

- increasing the distance between the gears due to their wear.

Crunch at the beginning of the movement

Crunching when starting the car may indicate:

- wear of the landing nests of the axis of the satellites;

- shank backlash;

- change in the gap in the connection of the drive gear and flange.

How to check the rear axle

Naturally, noises such as hum, vibration, crackling or knocking can also occur due to other malfunctions. For example, the same propeller shaft, if an outboard bearing breaks or a crosspiece fails, can make a crunch and vibrate. Breakage of the elastic coupling "cardan" is also accompanied by similar symptoms. Rear racks or other suspension elements can knock. In any case, before starting the repair of the bridge, it is important to make sure that it is he who is faulty.

The rear axle is checked as follows:

- We leave on a flat section of the road without holes and ledges.

- We accelerate the car to 20 km / h.

- We listen and note the accompanying noises.

- We gradually increase the speed of the car to 90 km / h and remember at what speed this or that uncharacteristic sound occurs.

- Without turning off the gear, we release the accelerator pedal, extinguishing the speed with the engine. We continue to monitor the change in the nature of the noise.

- Again we accelerate to 90-100 km / h, turn off the gear and ignition, allowing the car to coast. If the extraneous noise has not disappeared, the rear axle gearbox is in order. Without load, it cannot make noise (except for bearings). If the sound disappears, the gearbox is probably defective.

- We check the tightness of the wheel bolts by tightening them with a wheelbrace.

- We install the car on a horizontally flat surface. We hang out its rear wheels with a jack, so that we can rotate them freely.

- We alternately rotate the wheels of the car left and right, and also push back and forth in order to determine the backlash. The wheel should spin freely without binding. If, with the bolts securely tightened, the wheel plays or brakes, most likely the axle shaft bearing is worn.

- With the gear engaged, we rotate each of the wheels around its axis. We look at the behavior of the cardan shaft. It also needs to spin. If it does not rotate, most likely the axle shaft is broken.

Video: extraneous noises in the stern of the car

Repair of the rear axle VAZ 2101

The process of repairing the rear axle is a rather time-consuming task, requiring certain skills and special equipment. If you do not have enough experience and the necessary tools, it is better to contact a car service.

Replacement of axle shafts, their bearings and seals

To replace a deformed or broken axle shaft, its bearing, oil seal, it will be necessary to dismantle the wheel and partially disassemble the beam. Here we will need:

- car jack;

- wrench for wheel bolts;

- stand for car body;

- wrenches on "8" ("12") and on "17";

- flat screwdriver;

- round nose pliers or pliers;

- a hammer;

- large chisel;

- "Bulgarian" with the ability to connect to the mains;

- gasoline blowtorch or gas burner;

- vice;

- grease.

In addition, the spare parts themselves, which are planned to be replaced, will be required, namely the axle shaft, bearing, locking ring, oil seal. The table below shows the catalog numbers and specifications of the required parts.

Table: characteristics of the replaceable axle shaft elements

| Name | Index | ||

| rear axle shaft | |||

| Parts Catalog Number | 2103 – 2403069 Feet | ||

| Rear axle shaft bearing | |||

| Catalog number | 2101 – 2403080 Feet | ||

| Marking | 306 | ||

| View | Ball | ||

| Row | Single row | ||

| Diameter, mm | 72/30 | ||

| Height, mm | 19 | ||

| Maximum load capacity, N | 28100 | ||

| Mass, g | 350 | ||

| Locking ring | |||

| Parts Catalog Number | 2101 – 2403084 Feet | ||

| Rear axle oil seal | |||

| Catalog number | 2101 – 2401034 Feet | ||

| Frame material | rubber rubber | ||

| GOST | 8752 – 79 Feet | ||

| Diameter, mm | 45/30 | ||

| Height, mm | 8 | ||

Work order:

- We place the car on a horizontally flat surface, fix the front wheels.

- Using a wheel wrench, unscrew the wheel bolts.

- Raise the rear of the car body on the desired side with a jack. We fix the body with a safety stand.

- Completely unscrew the bolts, remove the wheel.

- We unscrew the drum guides with the key to "8" or to "12". We remove the drum.

The drum studs are unscrewed with a key to "18" or to "12"

The drum studs are unscrewed with a key to "18" or to "12" - Using the key on “17”, we unscrew the four nuts that fix the axle shaft.

The shaft is attached with four bolts.

The shaft is attached with four bolts. - Carefully remove spring washers.

Washers are easier to remove with round nose pliers

Washers are easier to remove with round nose pliers - Pulling the half shaft towards you, we remove it from the casing. If the part does not lend itself, we fasten the previously removed wheel to it with the reverse side. By striking the wheel with a hammer through some kind of spacer, we knock out the axle shaft of their stocking.

If the axle shaft does not come out of the stocking, attach the wheel to it with the back side and carefully knock it out

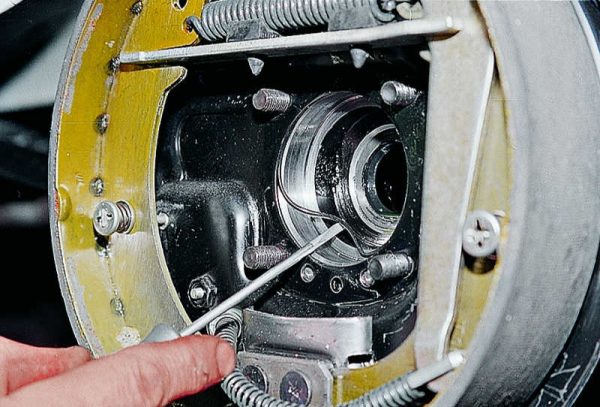

If the axle shaft does not come out of the stocking, attach the wheel to it with the back side and carefully knock it out - Remove the thin sealing ring with a screwdriver.

To remove the ring, pry it with a thin screwdriver

To remove the ring, pry it with a thin screwdriver - We take out the seal. If the axle shaft is broken or deformed, discard the axle shaft along with the oil seal and bearing. If the part is in working condition, we continue to work.

The old seal can be easily removed with pliers

The old seal can be easily removed with pliers - We fix the axle shaft in a vice and saw the fixing ring with a grinder.

To remove the ring, you need to cut it

To remove the ring, you need to cut it - Using a chisel and a hammer, split the ring. We knock him off the shaft.

- We knock down and remove the old bearing.

When the snap ring is removed, the bearing can be knocked down with a hammer.

When the snap ring is removed, the bearing can be knocked down with a hammer. - Remove the boot from the new bearing. We put grease under it, install the anther in place.

- We put the bearing on the shaft so that its anther is directed towards the oil deflector.

- We select a piece of pipe for shrinkage of the bearing. Its diameter should be approximately equal to the diameter of the inner ring, i.e. 30 mm. We rest the pipe in the ring and seat the bearing, striking with a hammer on its other end.

The bearing is installed by stuffing on the axle shaft

The bearing is installed by stuffing on the axle shaft - We heat the fixing ring with a burner.

Before installing a new ring, it must be heated

Before installing a new ring, it must be heated - We put the ring on the axle shaft and seat it hot in place with a hammer.

Locking ring is seated close to the bearing

Locking ring is seated close to the bearing - We wipe the seal seat. Lubricate the seal with grease and install it in the socket. We press in the oil seal using a spacer of a suitable diameter and a hammer.

The gland is pressed in with a spacer and a hammer

The gland is pressed in with a spacer and a hammer - We assemble in the reverse order.

Video: how to replace the half shaft bearing yourself

Watch this video on YouTube

Gearbox replacement

It is worth changing the gearbox only when you are completely sure that the problem lies in the wear of its gears. It is unlikely that it will be possible to select and install the final drive gears and satellites so that the gearbox works like new in a garage. This requires very precise adjustment, which not every specialist can perform. But you can replace the gearbox assembly yourself. It is not so expensive - about 5000 rubles.

Required tools and tools:

- hex key on "12";

- open-end wrenches for "13", "17", "19";

- mounting spatula or large screwdriver;

- clean container for draining grease.

Procedure:

- We hang out the rear part of the car body and perform the work provided for in paragraphs 1–8 of the previous instructions for both wheels. The axle shafts do not need to be fully extended. It is enough to pull them a little towards you so that the splines of their shafts disengage from the gears of the gearbox.

- Using a hexagon on “12”, we unscrew the drain plug in the crankcase, after substituting a container under it.

To unscrew the cork, you need a hex key on "12"

To unscrew the cork, you need a hex key on "12" - To make the oil glass faster, use the key to “17” to unscrew the filler plug.

- When the oil drains, remove the container to the side, screw the plugs back.

- Using a mounting spatula or a large screwdriver, fix the cardan shaft. At the same time, using the key on “19”, we unscrew in turn the four nuts securing the shaft to the shank flange.

Cardan is held by four nuts

Cardan is held by four nuts - Using a screwdriver, disconnect the flanges of the nodes. We take the "cardan" to the side and hang it in the lower part of the body.

When the nuts are unscrewed, the shaft must be shifted to the side

When the nuts are unscrewed, the shaft must be shifted to the side - We unscrew the eight bolts securing the gearbox to the crankcase of the beam with the key to "13".

The gearbox is held on by eight bolts.

The gearbox is held on by eight bolts. - Carefully remove the gearbox and sealing gasket. The gasket during the subsequent installation of the assembly will need to be replaced, especially if oil leaks were observed at the junction of the nodes before the repair.

When installing a new assembly, replace the sealing gasket

When installing a new assembly, replace the sealing gasket - We put a new one in place of the faulty node, after which we assemble it according to the reverse algorithm.

Video: gearbox replacement

Watch this video on YouTube

Gearbox disassembly, shank bearing replacement

The shank bearing must be replaced if there is even minimal axial play in the pinion shaft. You can check its presence by staggering the gear shaft. If there is play, then the bearing is defective.

The oil seal is changed when an oil leak is detected in the area of the shank flange. You can replace it without resorting to dismantling the gearbox. It is enough to disconnect the cardan shaft.

Table: technical characteristics of the bearing and oil seal of the VAZ 2101 gearbox shank

| Name | Index |

| Shank bearing | |

| Catalogue number | 2101 – 2402041 Feet |

| Marking | 7807 |

| View | Roller |

| Row | Single row |

| Diameter (outer/inner), mm | 73,03/34,938 |

| Weight, g | 540 |

| Shank oil seal | |

| Catalogue number | 2101 – 2402052 Feet |

| Frame material | Acrylate rubber |

| Diameter (outer/inner), mm | 68/35,8 |

Tools:

- small mount;

- keys for "10", "14", "27";

- torque wrench;

- round nose pliers or pliers;

- drift;

- a hammer;

- piece of steel pipe.

Replacement process:

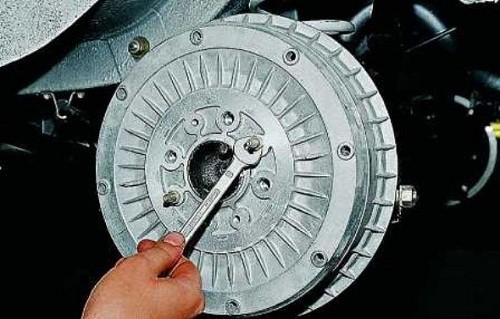

- We insert two previously unscrewed bolts into the holes of the gearbox flange.

- We thread the mount between the bolts and fix the flange from turning. At the same time, using the “27” wrench, unscrew the flange fixing nut.

To unscrew the flange fastening nut, it must be fixed with a mount

To unscrew the flange fastening nut, it must be fixed with a mount - Remove the flange.

When the nut is unscrewed, the flange will easily come off the shaft.

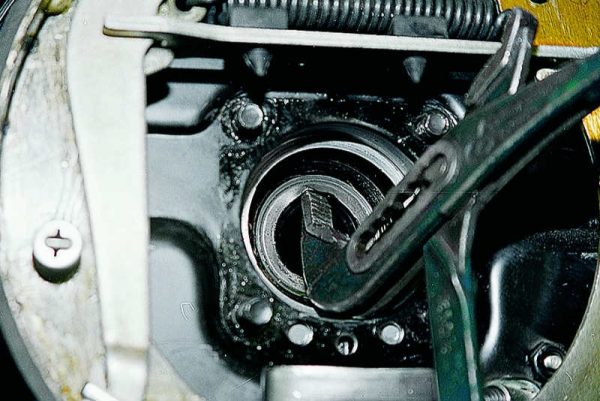

When the nut is unscrewed, the flange will easily come off the shaft. - With the help of pliers, we remove the gland from the socket.

It is convenient to extract the shank gland with pliers with elongated “lips”

It is convenient to extract the shank gland with pliers with elongated “lips” - If only replacement of the gland is required, lubricate the socket with grease, put a new part in place of the faulty part and press it in with a hammer and a piece of pipe.

To install the gland, use a piece of pipe of the desired diameter

To install the gland, use a piece of pipe of the desired diameter - We twist the flange nut and tighten it, adhering to the moment of 12–25 kgf.m.

The nut is tightened with a torque wrench with a torque of 12–25 kgf.m

The nut is tightened with a torque wrench with a torque of 12–25 kgf.m - If it is necessary to replace the bearing, we perform further disassembly of the gearbox.

- We fix the gearbox in a vice.

- Using the key to "10" unscrew the bolts fixing the locking plates on both sides.

To remove the plate, you need to unscrew the bolt with a key to "10"

To remove the plate, you need to unscrew the bolt with a key to "10" - We make marks on the cover and on the bed of the bearing. This is necessary in order not to make a mistake with their location during the subsequent assembly.

Marks can be applied with a punch or screwdriver

Marks can be applied with a punch or screwdriver - We turn out the bolts of the covers with the key to "14".

The bolts are unscrewed with a key to "14"

The bolts are unscrewed with a key to "14" - We take out the rings and adjustment nuts.

The outer ring of the bearing is located under the adjusting nut.

The outer ring of the bearing is located under the adjusting nut. - We take out the "insides" of the gearbox.

To remove the drive gear, you need to remove the driven

To remove the drive gear, you need to remove the driven - We remove the gear from the gearbox along with the spacer sleeve.

gear is removed with bearing and bushing

gear is removed with bearing and bushing - Using a drift, we knock the bearing off the “tail” of the gear. Under it is an adjusting washer, which ensures the correct position of the gears. We don't shoot it.

The bearing must be knocked off the shaft with a soft metal drift.

The bearing must be knocked off the shaft with a soft metal drift. - Installing a new bearing.

- We fill it with a hammer and a piece of pipe.

- We install the gear in the gearbox, we assemble it.

- We install a new seal. We press it in, and tighten the flange fixing nut, as indicated earlier.

Rear axle oil

According to the recommendations of the auto manufacturer, the VAZ 2101 drive axle gearbox should be filled with oil that meets the GL-5 class according to the API system and the viscosity class 85W-90 according to the SAE specification. Such requirements are met by a domestically produced lubricant of the TAD-17 type. This is a special gear lubricant for use in gearboxes and hypoid gears. It is recommended to change it every 50000 km.

How to change the oil

Approximately 2101–1,3 liters of lubricant is placed in the VAZ 1,5 rear axle gearbox. To change the oil, the car will need to be installed on a viewing hole.

The order of work is as follows:

- Using the key on "17", unscrew the filler plug.

The cork is unscrewed with a key to "17"

The cork is unscrewed with a key to "17" - Install a container under the drain hole to collect the old grease.

- Unscrew the drain plug with a hex wrench on "12".

Before unscrewing the plug, you need to substitute a container under it to collect the old grease.

Before unscrewing the plug, you need to substitute a container under it to collect the old grease. - While the oil drains into the bowl, wipe the drain plug with a clean rag. A magnet is installed inside it, and it attracts the smallest metal particles formed due to wear of the gearbox parts. Our task is to get rid of this shavings.

- When the oil drains, tighten the drain plug.

Remove metal particles and dirt from the cork before screwing

Remove metal particles and dirt from the cork before screwing - With the power of a special syringe or other device, pour lubricant into the upper hole. You need to pour oil until the moment when it starts to pour out. This will be the correct level.

Oil is poured using a special syringe

Oil is poured using a special syringe - At the end of the work, we twist the filler hole with a stopper.

Video: oil change in the rear axle gearbox VAZ 2101

Watch this video on YouTube

As you can see, everything is not so difficult. Change the lubricant in a timely manner, pay attention to minor malfunctions, eliminate them as far as possible, and the bridge of your “penny” will serve you for more than one year.