Chain tensioner VAZ 2107: purpose, types, signs of wear, replacement

Content

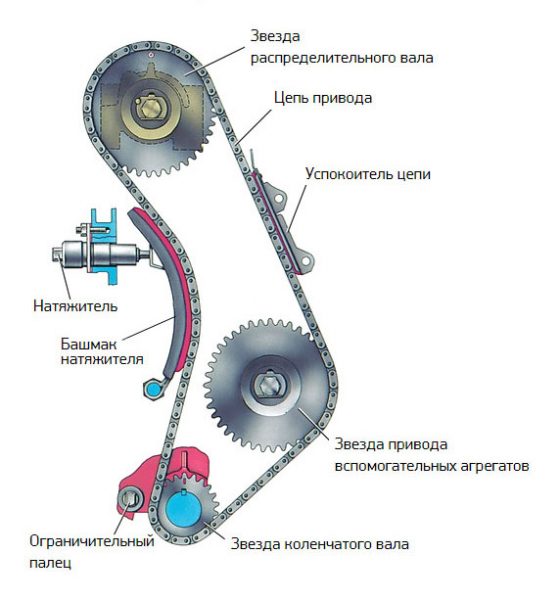

On the VAZ 2107, the timing mechanism is driven by a chain drive, which ensures trouble-free operation of the motor. To ensure that the chain is constantly in tension, a tensioner is used. This mechanism is of several types, each of which has its pros and cons. As the car is used, the part can fail, so you need to know how to properly replace it.

Timing chain tensioner VAZ 2107

The VAZ 2107 car was equipped with motors with a timing belt and chain drive. Although the chain is more reliable than the belt, nevertheless, the device of the drive unit is imperfect and requires periodic tension, for which a special mechanism is used - the tensioner.

Purpose of the device

The chain tensioner in the power unit performs an important function by controlling the chain tension in the timing drive. It follows from this that the coincidence of the valve timing and the stable operation of the motor directly depend on the reliability of this product. When the chain is loosened, the damper breaks. In addition, it can jump over the teeth, causing the valves to hit the pistons, which will lead to engine failure.

Read more about the belt drive device on the VAZ 2107: https://bumper.guru/klassicheskie-modeli-vaz/grm/grm-2107/metki-grm-vaz-2107-inzhektor.html

Types of tensioners

The timing chain tensioner comes in several varieties: automatic, hydraulic and mechanical.

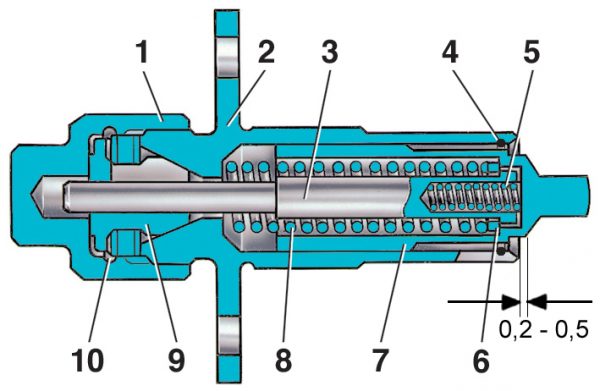

Mechanical

In a mechanical type tensioner, the required amount of tension is provided by a plunger spring. Under its influence, the rod leaves the body and pushes the shoe. The force is transmitted until the chain begins to resist, i.e., it is sufficiently stretched. In this case, sagging is excluded. The tensioner is fixed by tightening the cap nut located outside. When it is necessary to adjust the tension, the plunger retainer nut is unscrewed, as a result of which the spring compresses the stem, eliminating slack in the chain.

Such tensioners are characterized by one significant drawback: the device becomes clogged with small particles, which leads to jamming of the plunger. To eliminate this malfunction, tap on the tensioner during adjustment. However, you should not make special efforts so as not to damage the body of the product.

Learn how to replace the timing chain: https://bumper.guru/klassicheskie-modeli-vaz/grm/grm-2107/zamena-cepi-grm-vaz-2107-svoimi-rukami.html

Automatic

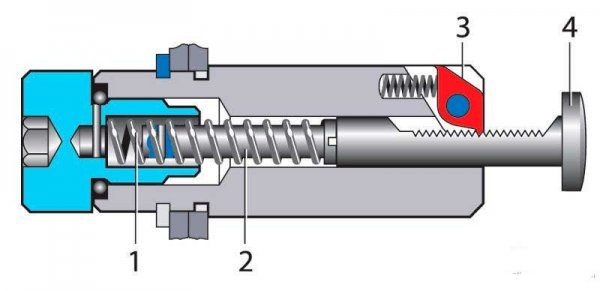

This type of tensioner structurally has a ratchet. The product consists of a body, a spring-loaded pawl and a toothed bar. The teeth are made with a slope in one direction with a step of 1 mm. The working principle of the automatic product is as follows:

- The spring of the device acts on the toothed bar with a certain force, depending on how much the chain sags.

- The force is transmitted to the tensioner shoe by means of the bar.

- Backlash is prevented thanks to the ratchet pawl providing fixation.

- The stopper, falling between the teeth, prevents the bar from moving backwards.

With this principle of operation, there is a constant effect of the spring on the bar responsible for the tension of the chain, and thanks to the ratchet mechanism, the chain drive is constantly in a taut state.

Гидравлический

Today, hydraulic chain tensioners are used as an alternative in timing systems. For the operation of the part, lubrication from the engine under pressure is used. This allows you to maintain the required tension, which does not require manually tensioning the chain mechanism.

In such a mechanism there is a hole for supplying oil. Inside the product there is a transition device with a ball, which is under high pressure and is regulated by a pressure reducing valve. Thanks to the threaded plunger device, the hydraulic tensioner is able to control the condition of the chain even when the engine is turned off.

Tensioner malfunctions

The main problems with the chain tensioner include:

- breakdown of the collet mechanism, as a result of which the rod is not fixed and the chain is not normally tensioned;

- wear of the spring element;

- breakage of the damper spring;

- large wear of the rod near the fastening of the collet clamp;

- damage to the threads on the fastening studs.

In most cases, if there are problems with the tensioner, the part is replaced with a new one.

Removing the tensioner

The need to remove and replace the mechanism arises when it does not cope with its function. An insufficient chain tension is indicated by a characteristic metallic sound coming from the front of the motor or a knock from under the valve cover. It is possible that the tensioner shoe also needs to be replaced. To begin with, consider a simpler repair option, in which shoe replacement is not required.

To work, you will need the following tools:

- open-end wrench for 10 and 13;

- tensioner with gasket.

Dismantling is simple and is carried out as follows:

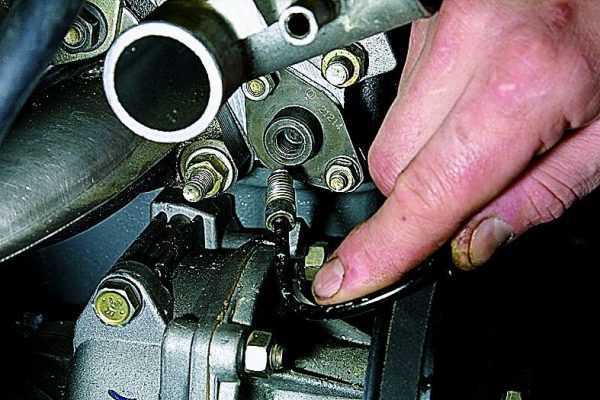

- We unscrew 2 tensioner fastening nuts with a key of 10: the part is located on the right side of the motor near the pump.

To remove the chain tensioner, unscrew 2 nuts by 10

To remove the chain tensioner, unscrew 2 nuts by 10 - We take out the device from the block head. If there is no new gasket, you need to dismantle it carefully so as not to tear it.

After unscrewing the fasteners, remove the tensioner from the head of the block

After unscrewing the fasteners, remove the tensioner from the head of the block

Tensioner problems are usually in the collet. To check, it is enough to unscrew the cap with a key of 13. If it was found that the petals of the mechanism were broken inside the nut, then the nut itself or the entire tensioner could be replaced.

Replacing the shoe

The main reason for changing the shoe is its damage or the impossibility of chain tension. To replace a part you will need:

- Screwdriver Set;

- set of wrenches;

- wrench to rotate the crankshaft or head 36.

Dismantling is carried out as follows:

- Remove the engine crankcase protection.

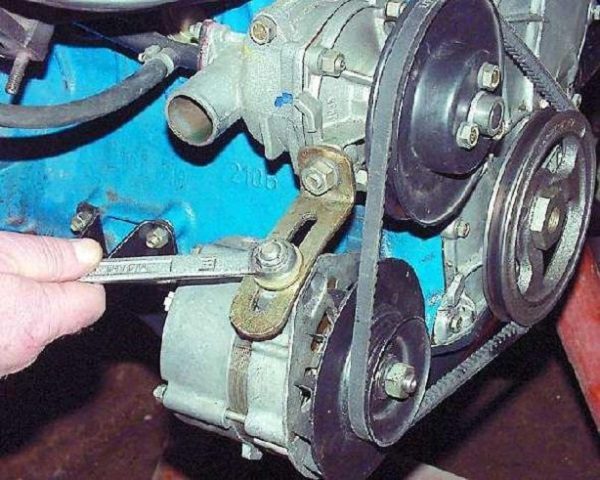

- We loosen the upper bolt of the generator and remove the belt.

To remove the alternator belt, you will need to release the upper mount

To remove the alternator belt, you will need to release the upper mount - We dismantle the casing together with the fan.

To get to the front cover of the engine, it is necessary to dismantle the fan

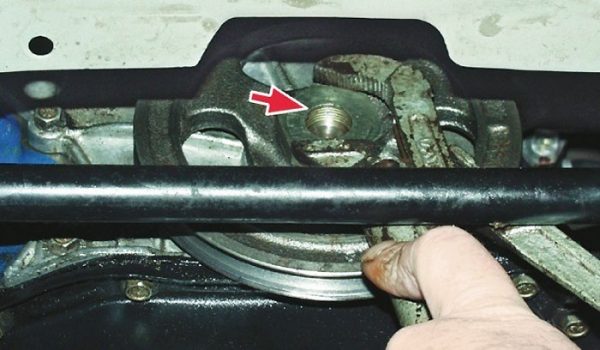

To get to the front cover of the engine, it is necessary to dismantle the fan - We unscrew the nut securing the crankshaft pulley and remove the pulley.

Unscrew the nut securing the crankshaft pulley with a special or adjustable wrench

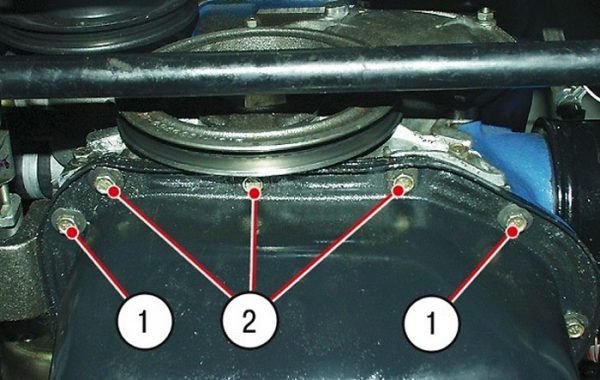

Unscrew the nut securing the crankshaft pulley with a special or adjustable wrench - Weaken and turn out the fastening of the pallet.

We unscrew the fastening of the oil pan in front of the engine

We unscrew the fastening of the oil pan in front of the engine - We unscrew the fasteners of the front cover of the engine.

To dismantle the front cover, unscrew the fasteners

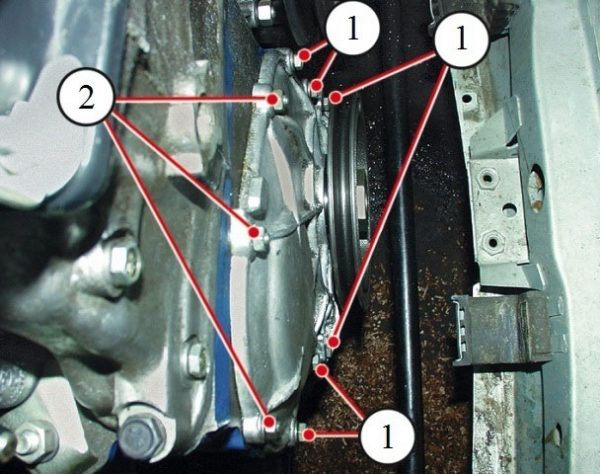

To dismantle the front cover, unscrew the fasteners - We pry off the cover with a screwdriver and remove it together with the gasket.

Prying off the cover with a screwdriver, carefully remove it together with the gasket

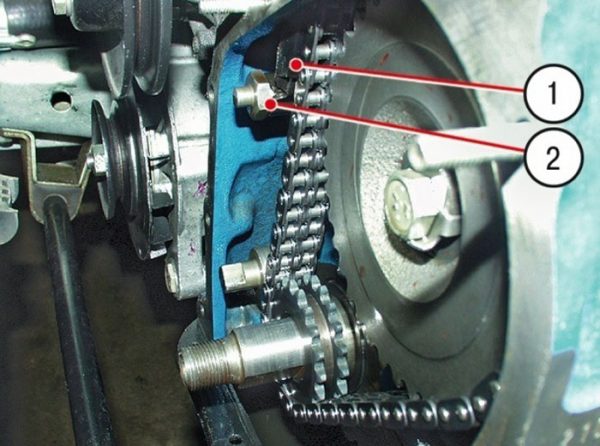

Prying off the cover with a screwdriver, carefully remove it together with the gasket - We unscrew the tensioner mounting bolt (2) and remove the shoe (1) from the engine.

We unscrew the mount and remove the tensioner shoe

We unscrew the mount and remove the tensioner shoe

The new part is mounted in reverse order.

Read how to unscrew a bolt with worn edges: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/kak-otkrutit-bolt-s-sorvannymi-granyami.html

Video: replacing the chain tensioner shoe using the VAZ 2101 as an example

Tensioner installation

To install a new tensioner, it is necessary to put the part on the end and press the stem into the body. In this position, tighten the cap nut, after which you can put the mechanism on the machine, not forgetting the gasket. Upon completion of the procedure, the tensioner nut is released and the chain drive is tensioned, followed by tightening the nut.

Modification of the mechanical tensioner

Despite the variety of tensioners, each of them has its drawbacks: hydraulic tensioners require the installation of an oil supply tube, wedged and are expensive, auto-tensioners are characterized by low reliability and are also expensive. The problem of mechanical products comes down to the fact that the oil that gets on the rod and collet does not allow the cracker to hold the rod in the desired position, as a result of which the adjustment is lost and the chain is weakened. Plus, the plunger itself can wedge. As you know, the simpler the design, the more reliable. Therefore, there is a way to modify the mechanical type tensioner.

The essence of the changes is to replace the collet with a thrust bolt, which is fixed in a cap nut. To do this, you must perform the following steps:

- We unscrew the cap nut and take out the cracker, which is fixed with a special stopper.

We unscrew the cap nut and take out the cracker, which is fixed with a stopper

We unscrew the cap nut and take out the cracker, which is fixed with a stopper - We drill a hole with a diameter of 6,5 mm in the nut from the inside.

A hole with a diameter of 6,5 mm must be drilled in the cap nut

A hole with a diameter of 6,5 mm must be drilled in the cap nut - In the resulting hole, we cut the thread M8x1.25.

- We wrap the M8x40 wing bolt with the M8 nut screwed onto it into the cap nut.

We wrap the wing bolt into the cap nut with threaded threads

We wrap the wing bolt into the cap nut with threaded threads - We assemble the tensioner.

After the steps taken, the tensioner is assembled

After the steps taken, the tensioner is assembled - We start the engine and, by the sound of the chain drive, set the tension, and then tighten the nut.

If the chain rattles during adjustment, the lamb needs to be twisted. If you add gas and a hum is heard - the chain is too tight, which means that the bolt should be loosened slightly.

How to tension the chain

Before proceeding with adjusting the chain tension on the VAZ 2107, it is worth noting that the timing mechanisms on injection and carburetor engines are exactly the same. Chain tensioning consists of the following steps:

- On a car with the engine turned off, open the hood and loosen the tensioner nut with a 13 wrench.

- Turn the crankshaft with a wrench 2 turns.

- Tighten the tensioner.

- They start the engine and listen to its work.

- If there is no characteristic metallic sound, then the procedure was successful. Otherwise, all actions are repeated.

Since the chain is subjected to heavy loads during operation, its adjustment should be carried out every 15 thousand km.

Video: how to pull the chain on the VAZ 2101-2107

Watch this video on YouTube

Timely detection of tensioner problems and replacement of the mechanism will avoid serious engine damage. After reviewing the sequence of actions, each car owner will be able to carry out repair work, which will require a minimum set of tools.