Purpose, malfunctions and replacement of the front shock absorbers VAZ 2107

Content

In order for the VAZ “seven” to be controlled not only conveniently, but also safely, the state of the suspension has to be monitored periodically. An important element in its design are shock absorbers, the replacement of which can be carried out by each owner of this car.

Front shock absorber VAZ 2107

The suspension design of any car uses shock absorbers that increase the comfort and safety of movement. Since the VAZ 2107 shock absorbers, like other suspension elements, are subjected to constant loads and fail over time, you need to know how malfunctions manifest themselves and be able to replace the part if necessary.

appointment

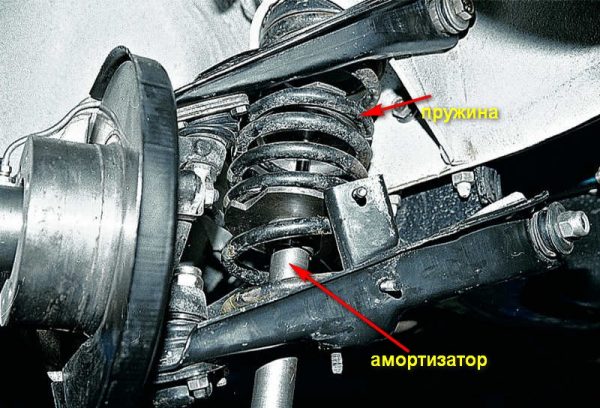

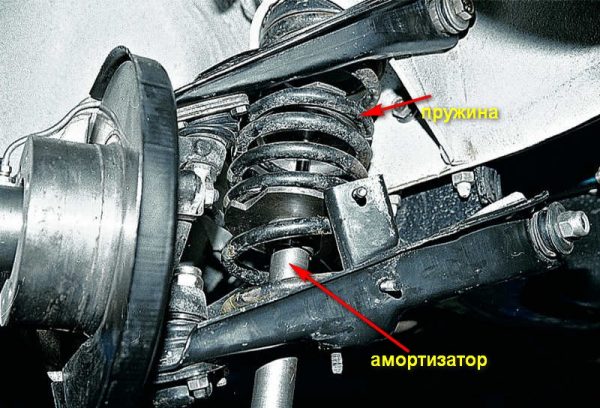

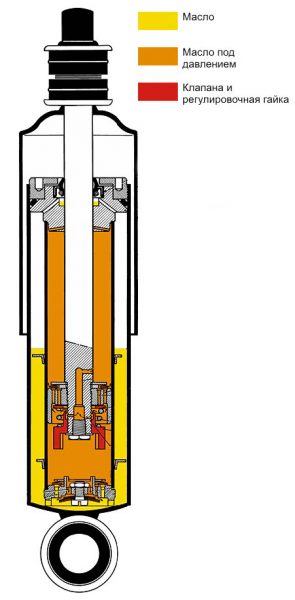

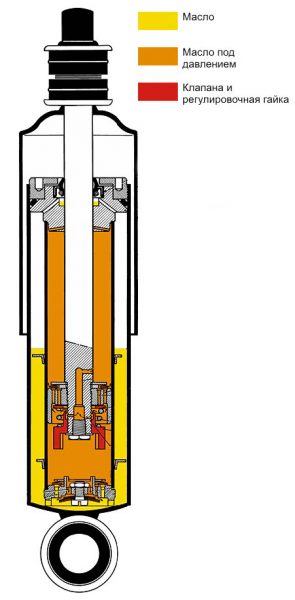

The normal and correct operation of the front suspension of the "seven", and the rear too, is ensured by the main structural elements - a spring and a shock absorber. The spring softens the shocks of the body while the car is moving. When hitting any kind of obstacles (potholes, bumps), the wheel comes off the road, and thanks to the elastic element, it returns to work. During the impact of the wheel on the surface, the body presses down with its entire mass, and the spring should make this contact as soft as possible. The work of the shock absorber is aimed at the fastest possible damping of the vibrations of the elastic element during the buildup of the body. The part is completely sealed and, when fully operational, is capable of absorbing about 80% of impact energy. The shock absorbers of the front suspension of the VAZ 2107 are attached with a lower eyelet through the bracket to the lower suspension arm. The damper rod is fixed through the support cup with a nut.

Table: parameters of standard front shock absorbers VAZ 2107

| SKU | Rod diameter, mm | Case diameter, mm | Body height (excluding stem), mm | Rod stroke, mm |

| 21012905004, 21012905402 | 12 | 41 | 215 | 112 |

Устройство

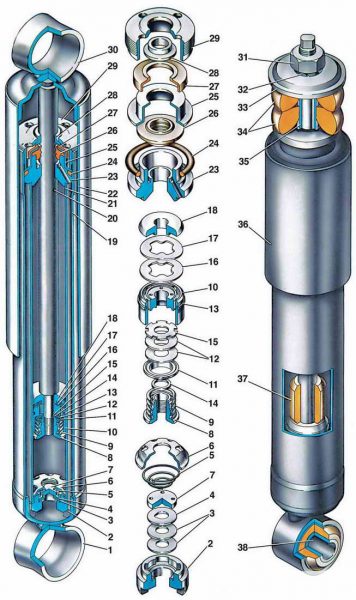

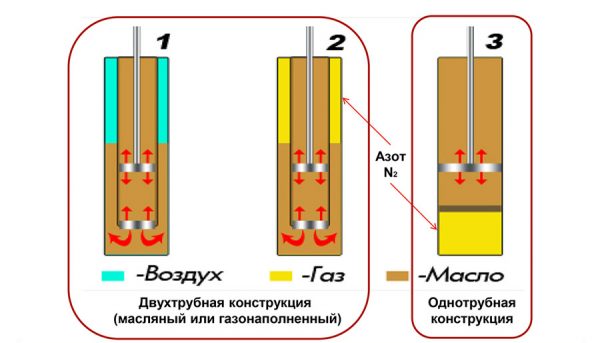

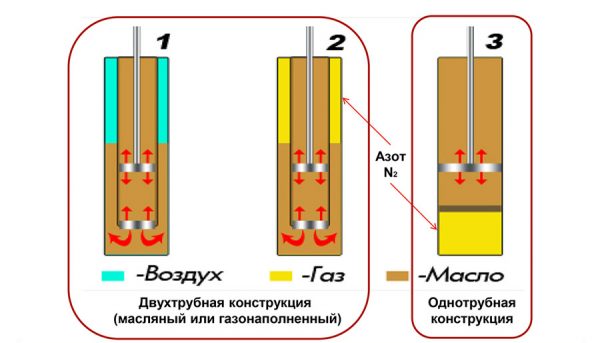

On the front end of the VAZ 2107 from the factory there are oil two-pipe shock absorbers. Structurally, in addition to the flask, piston and rod, they have another cylinder with a flask containing liquid and a piston element. During operation, the liquid is compressed by the piston, which causes it to flow through the valve into the outer cylinder. As a result, the air is further compressed. During rebound, due to the opening of the valves on the piston, the liquid flows again into the inner cylinder. This design of shock absorbers, although simple, has certain disadvantages. Since the liquid from one flask to another passes through the valves under high air pressure, aeration occurs, in which the liquid mixes with air, causing its properties to deteriorate. In addition, due to the two flasks, the damper cools worse, which reduces its effectiveness.

Shock absorber malfunctions

Any malfunction of the car always manifests itself in the form of extraneous noise, non-standard behavior of the vehicle or other signs. Shock absorber failures also have certain symptoms, upon detection of which it is not worth delaying the replacement of dampers.

Oil leaks

The most common sign that a shock absorber has failed is fluid leakage. Leaks on the body indicate a loss of tightness of the oil reservoir. As a result, not only leaks occur, but also air leakage. In this case, the damper rod has free play, i.e., it moves without any effort, and the part loses its performance. If signs of smudges have just appeared on the shock absorber, it will serve a little more, but you should not leave it unattended and it is better to replace it in the near future.

body swing

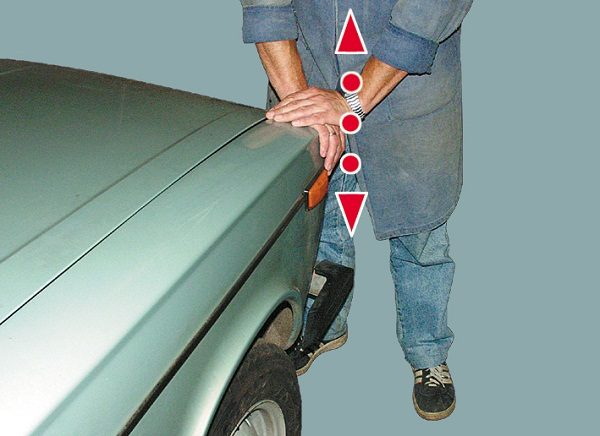

Since the springs and dampers work together to dampen vibrations that occur when driving over bumps, contact with the road can be lost if the damper fails. In this case, shaking increases, the body sways, and the comfort level decreases. The car becomes rolled, and when it hits obstacles, it sways for a while. The easiest way to check the shock absorbers of your "seven" is to press on the wing, trying to shake the body, and then release it. If the car continues to rock on the springs for some time, then this is a clear sign of a damper malfunction.

body roll

One symptom that indicates problems with suspension dampers is body roll when cornering. This behavior of the car negatively affects safety, as the quality of braking suffers, as well as vehicle control. If liquid has leaked out of the damper, it will be quite difficult to keep the car on the turn, which is especially dangerous in winter. With a run of the products in question of more than 60 thousand km, which also depends on the quality of the parts themselves and the operating conditions of the machine, the handling may noticeably deteriorate. But since the process does not occur at one moment, but gradually, the driver practically does not notice this and rolls can be perceived as a normal phenomenon.

Suspension noise

Extraneous sounds in the suspension, uncharacteristic of its operation, indicate the need to check and maintain this mechanism. When the dampers and their bushings are worn, the ability to effectively support the weight of the machine is lost. In addition, so-called breakdowns of shock absorbers often occur.

Suspension breakdowns are metal elements touching each other, which leads to a knock.

Uneven or increased tire wear

If it has been noticed that the tire tread has uneven wear or wears out too quickly, then this is a clear sign of suspension problems. With faulty shock absorbers, the wheel moves vertically with a much greater amplitude, which leads to uneven tire wear. While driving on such wheels, extraneous noise appears.

Pecks when braking

Among car owners there is such a thing as "the car bites." With failed dampers, during braking, the front of the car pecks, and when accelerating, the rear sags. This is explained by the fact that the parts that have become unusable do not cope with their function, that is, they do not hold the weight of the machine.

Fastening break

One of the infrequent breakdowns of the front shock absorbers is the breakage of the lower lug. The reasons for this phenomenon may be different:

- installation of a low-quality part;

- changes to the standard suspension design.

Sometimes it happens that the stem mount breaks along with the glass. This phenomenon is accompanied by a knock during movement. Identifying a breakdown is quite simple by opening the hood and looking at the place where the upper part of the shock absorber is attached.

The problem is eliminated by welding. Some Zhiguli owners reinforce this part of the body with additional metal elements.

Checking shock absorbers on the stand

The most accurate method for diagnosing shock absorbers is to test the vehicle's suspension on a vibration stand. On such equipment, the properties of each damper are checked separately. Upon completion of the diagnostics, the device will display a diagram based on the results of measurements of axial vibrations. By comparing the diagram with the allowable vibration of a healthy damper, it will be possible to understand the state of the parts.

Video: diagnostics of car dampers at the stand

Replacing the front shock absorber on the "seven"

Front suspension dampers in the event of a breakdown are usually replaced with new ones. Sometimes owners try to repair them on their own, which requires some experience, the purchase of a repair kit and special oil, but only collapsible shock absorbers are suitable for this procedure. Before proceeding with the replacement, you need to decide which elements to install on your car.

Choice of shock absorbers

The question of choosing dampers for the "seven" is quite difficult for many, due to the wide variety of such products. On the "classic" you can put the following types of shock absorbers:

- oil;

- gas-oil with constant hardness;

- gas-oil with variable hardness.

Each type is characterized by its pros and cons, produced by different manufacturers. It is necessary to choose a product based on the operating conditions of the vehicle and the driving style of the owner.

Oil

Although the “seven” is basically equipped with oil shock absorbers filled with hydraulic fluid, many do not like their work. The main disadvantage of such dampers is the slow response. If the machine is moving at high speed, the shock absorber does not have time to return to working condition, which leads to wiggle on the springs. Therefore, they are recommended to be installed by those owners who do not operate cars at a speed of more than 90 km / h.

Gas-oil

Gas-oil shock absorbers use oil and gas, which increases the efficiency of the product, improves the development of irregularities. The main working medium is oil, while the gas stabilizes the operation, removing excess foam and increasing the efficiency of response to changes in road conditions. Equipping the Zhiguli with such dampers has a positive effect on driving performance. The buildup at relatively low speeds is practically absent. Of the minuses, it is worth highlighting the gaps during sharp blows.

Gas-oil with variable hardness

On the "seven", as well as on the other "classics", such elements are practically not installed, due to the high price. Products of this type are equipped with a special valve with an electromagnet. Through the valve, it adjusts to the mode of operation of the car and adjusts the amount of gas in the main cylinder of the damper with a change in the rigidity of the device.

Video: types of shock absorbers and their difference

Watch this video on YouTube

Manufacturers

During repairs, many owners install standard elements. Those who want to improve the performance of the suspension, purchase gas-oil components. However, one has to choose from foreign manufacturers, since domestic manufacturers do not produce such products. The most popular brands include:

- Kayaba;

Kayaba shock absorbers are one of the most common when installed on classic Zhiguli

Kayaba shock absorbers are one of the most common when installed on classic Zhiguli - Sachs;

- Fenox;

- SS20.

Table: analogues of front dampers for the VAZ "classic"

| Manufacturer | SKU | price, rub. |

| KYB | 443122 (oil) | 700 |

| KYB | 343097 (gas) | 1300 |

| Fenox | A11001C3 | 700 |

| SS20 | SS20177 | 1500 |

| Sachs | 170577 (oil) | 1500 |

How to remove

To dismantle a faulty shock absorber, we need:

- keys for 6, 13, 17;

- jack.

The event consists of the following:

- We hang out the front of the car with a jack.

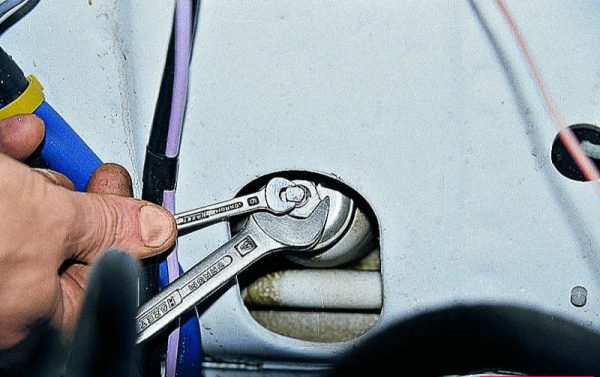

- We open the hood, in the hole of the mudguard we unscrew the upper shock absorber mount with a key of 17, holding the rod with a key of 6.

To unscrew the upper fastener, hold the stem from turning and unscrew the nut with a 17 wrench

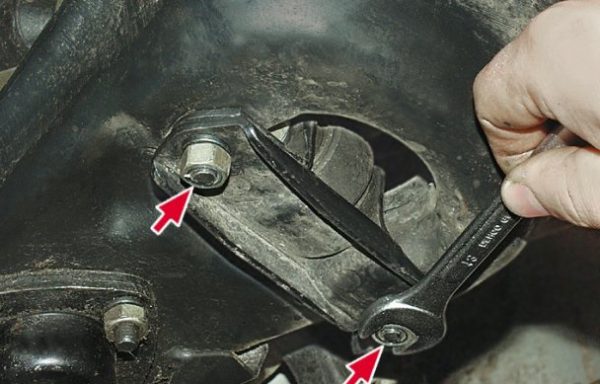

To unscrew the upper fastener, hold the stem from turning and unscrew the nut with a 17 wrench - We move under the car and turn off the bracket mount.

From below, the shock absorber is attached to the lower arm through the bracket

From below, the shock absorber is attached to the lower arm through the bracket - We remove the damper through the hole in the lower arm.

Having unscrewed the mount, we take out the shock absorber through the hole of the lower arm

Having unscrewed the mount, we take out the shock absorber through the hole of the lower arm - With two keys for 17, we unscrew the bracket mount and dismantle it.

We unscrew the fastening of the bracket with the help of two keys for 17

We unscrew the fastening of the bracket with the help of two keys for 17

Video: replacing front dampers on classic Zhiguli

Watch this video on YouTube

How to prepare for installation

The process of installing shock absorbers on the VAZ 2107 does not cause any difficulties. However, for proper and long-term work, they need to be prepared - pumped. Since the procedure differs depending on the type of device, we will dwell on the preparation of each of them in more detail.

Bleeding oil shock absorbers

We pump oil-type dampers according to the following algorithm:

- We install the product with the rod down and gradually compress.

- We wait a few seconds, holding the part with our hands in the same position.

Turning the shock absorber over, gently press the rod and hold it in this position for a few seconds

Turning the shock absorber over, gently press the rod and hold it in this position for a few seconds - We turn the device over, holding the rod, leave the shock absorber in this position for a few more seconds.

- Fully extend the stem.

We turn the shock absorber into working position and raise the rod

We turn the shock absorber into working position and raise the rod - Turn the damper over again and wait about 3 seconds.

- We repeat the whole procedure several times (3–6).

- After pumping, we check the shock absorber, for which we make sharp movements with the rod. With such actions, there should be no failures: the part should work smoothly.

Bleeding gas shock absorbers

The procedure for gas dampers is as follows:

- Flip the piece upside down.

- Gently push down the stem and fix it for a few seconds.

- Turn the product over again and hold for no more than 6 seconds.

- Fully extend the stem.

- We turn the part over, pause for a couple of seconds and repeat steps 1–4 several times.

- We finish pumping at step 4.

- To check the performance of the part, we perform step 7 for pumping the oil shock absorber.

Video: preparation for operation of gas-oil shock absorbers

Watch this video on YouTube

How to put

Before mounting the shock absorber, it is recommended that the rod be fully extended. If the damper was removed due to wear of the rubber pads or silent block, we change them to new ones. Installation is carried out in the reverse order of removal.

If the front shock absorber of your "seven" is out of order, it is not necessary to contact the service for help - repairs can be done on your own without special tools and extensive experience in carrying out procedures of this kind. To replace the damper, it is enough to familiarize yourself with the algorithm of actions and follow them during work.