Malfunctions and replacement of the hub and axle shaft on the VAZ 2106

For safe operation of the car, its wheels must rotate without any problems. If they appear, then with the control of the vehicle there are nuances that can lead to an accident. Therefore, the condition of the hubs, axle shafts and their bearings must be periodically monitored, and if problems occur, they must be eliminated in a timely manner.

Front hub VAZ 2106

One of the important elements of the chassis of the VAZ 2106 is the hub. Through this part, the wheel can be rotated. To do this, a rim is screwed onto the hub, and the rotation itself is carried out thanks to a pair of wheel bearings. The main functions that are assigned to the hub are:

- connection of the wheel disk with the steering knuckle;

- ensuring a high-quality stop of the car, since a brake disc is fixed on the hub.

To know how hub malfunctions manifest themselves, as well as how to repair, you need to familiarize yourself with the device of this element. Despite the fact that the part is designed to perform complex functions, it is structurally quite simple. The main parts of the hub are the housing and bearings. The body of the part is cast, made of a durable alloy and processed on turning equipment. The hub fails quite rarely. The main malfunction of the product is the development of external bearing races at the installation sites.

Rounded fist

An equally important element of the chassis of the "six" is the steering knuckle. A force is transmitted to it from the steering trapezoid through the lever, as a result of which the wheels of the front axle are rotated. In addition, ball bearings (upper and lower) are attached to the assembly through the corresponding lugs. On the back of the steering knuckle is an axle on which a hub with bearings is put on. The hub element is fixed on the axle with a nut. The left trunnion uses a right-handed nut, the right trunnion uses a left-handed nut.. This was done in order to exclude the tightening of bearings on the move and to avoid their overheating and jamming.

An additional function of the steering knuckle is to limit the rotation of the wheels, while the part rests against the levers with special protrusions.

Malfunctions

The resource of the steering knuckle is practically unlimited, if you do not take into account the quality of roads and the neglect of adjusting wheel bearings. Sometimes the product can go up to 200 thousand km. The part is made of cast iron and is able to withstand heavy loads. However, if it fails, then the owners of the Zhiguli often change it along with the bearings and the hub. It is necessary to pay attention to the steering knuckle if the following symptoms appear:

- the car began to divert to the sides, and the problem is not eliminated by adjusting the alignment;

- it was noticed that the eversion of the wheels became with a smaller angle. The cause may be problems with both the steering knuckle and the ball joint;

- wheel wreck. This happens due to the breakdown of the threaded part of the steering knuckle or the ball joint pin, which happens relatively often on the Zhiguli;

- unregulated backlash. If the wheel bearings were adjusted out of time or incorrectly, then in the places of their installation the axis of the steering knuckle will gradually wear out, which will lead to the appearance of play, which cannot be eliminated by adjustment.

Sometimes it happens that during car repair a small crack is found on the steering knuckle. Some motorists are advised to fix the problem by welding. However, it must be taken into account that safety directly depends on the state of the steering knuckle. Therefore, such elements should not be repaired, but replaced with known-good or new ones.

How to increase wheel alignment

Many owners of the VAZ 2106 and other "classics" are interested in the issue of increasing the eversion of the wheels, since the model in question has a rather large turning radius, which is far from always convenient. Those who are seriously engaged in tuning their car simply install a set of suspension elements (levers, bipod) with changed parameters. However, such sets for an ordinary owner of the VAZ "six" may not be affordable, because for such a pleasure you will have to pay about 6-8 thousand rubles. Therefore, other more affordable options are being considered, and they are. You can increase the eversion of the wheels as follows:

- We install the car on the pit and dismantle the bipod mounted on the inside of the hub.

- Since the bipods have different lengths, we cut the longer part in half, remove the part, and then weld it back.

To make the eversion of the wheels large, it is necessary to shorten the steering arm

To make the eversion of the wheels large, it is necessary to shorten the steering arm - We mount details in place.

When the bipod is shortened, install them on the car

When the bipod is shortened, install them on the car - We cut down the limiters on the lower levers.

Stoppers need to be cut off on lower control arms.

Stoppers need to be cut off on lower control arms.

The described procedure allows you to increase the eversion of the wheels by about a third, when compared with the standard position.

Front wheel bearing

The main purpose of wheel bearings is to ensure uniform rotation of the wheels. Each hub uses two single-row roller bearings.

Table: wheel bearing parameters VAZ 2106

| Hub bearing | Parameters | ||

| inner diameter, mm | outer diameter, mm | width, mm | |

| outer | 19.06 | 45.25 | 15.49 |

| internal | 26 | 57.15 | 17.46 |

Hub bearings run about 40-50 thousand km. During the installation of new parts, they are lubricated for the entire service life.

Malfunctions

A broken wheel bearing can cause an accident. Therefore, their condition must be periodically monitored and extraneous sounds and non-standard behavior of the machine must be responded to in a timely manner. If play is detected, the elements need to be adjusted or replaced. The main symptoms that indicate problems with wheel bearings are:

- Crunch. Due to the destruction of the separator, the rollers inside the device roll unevenly, which leads to the appearance of a metallic crunch. The part is to be replaced.

- Vibration. With a large wear of the bearing, vibrations are transmitted both to the body and to the steering wheel. Due to severe wear, the product may jam.

- Pulling the car to the side. The malfunction is somewhat similar to the incorrect adjustment of the alignment, which is due to the wedging of the bearing.

How to check the bearing

If there is a suspicion that the wheel bearing on one of the sides on your car is faulty, you should perform the following steps to check its performance:

- Raise the front wheel.

- We put an emphasis under the lower lever, for example, a stump, after which we lower the jack.

- We take the wheel with both hands in the upper and lower parts and try to tilt it towards ourselves and away from ourselves. If the part is in good condition, then there should be no knocking and play.

To check the bearing it is necessary to hang out and shake the front wheel

To check the bearing it is necessary to hang out and shake the front wheel - We turn the wheel. A broken bearing will give itself away with a characteristic rattle, hum or other extraneous sounds.

Video: checking the wheel bearing on the "six"

How to adjust

If increased clearances were found in the bearings, they need to be adjusted. From the tools you will need:

- jack;

- chisel;

- torque wrench;

- head 27;

- a hammer.

The sequence of actions for adjustment is as follows:

- Raise the front of the car and remove the wheel.

- Using a hammer and chisel, we knock down the decorative cap from the hub.

We knock down the protective cap with a screwdriver or chisel and remove

We knock down the protective cap with a screwdriver or chisel and remove - We put the wheel in place, fixing it with a couple of bolts.

- We tighten the hub nut with a moment of 2 kgf.m.

We tighten the hub nut with a moment of 2 kgf.m

We tighten the hub nut with a moment of 2 kgf.m - Rotate the wheel left and right several times to self-align the bearings.

- We loosen the hub nut, while shaking the wheel, repeating step 3 of checking the bearings. You need to achieve a barely noticeable backlash.

- We stop the nut with a chisel, jamming the necks into the grooves on the trunnion axis.

To lock the nut, we use a chisel and a hammer, jamming the necks into the slots on the axis

To lock the nut, we use a chisel and a hammer, jamming the necks into the slots on the axis

It is recommended to replace the hub nut with a new one during the bearing adjustment, since the fasteners can fall into the same place and it will be impossible to lock it from turning.

Bearing replacement

During the operation of the bearings, the cage, rollers and the cages themselves wear out, so the part must only be replaced. To do this, you will need the same list of tools as when adjusting the clearance in bearings, plus you also need to prepare:

- key for 12 and 27;

- beard;

- head 17;

- crank;

- flat screwdriver;

- grease Litol-24.

We carry out the work as follows:

- Raise the front of the car and remove the wheel.

- We dismantle the brake pads and caliper. We fix the latter in the wheel niche to prevent tension on the brake hoses.

We remove the brake pads and caliper, hanging it in such a way as to eliminate the tension of the brake pipes

We remove the brake pads and caliper, hanging it in such a way as to eliminate the tension of the brake pipes - We unscrew the hub nut, remove the washer and the inner part of the bearing.

Unscrew the nut, remove the washer and the hub bearing

Unscrew the nut, remove the washer and the hub bearing - We remove the hub and the brake disc from the trunnion axis.

After unscrewing the nut, it remains to remove the hub from the car

After unscrewing the nut, it remains to remove the hub from the car - I open two pins.

The hub is attached to the brake disc with two pins, unscrew them

The hub is attached to the brake disc with two pins, unscrew them - Separate the hub and the brake disc with a spacer ring.

Having unscrewed the mount, we disconnect the hub, brake disc and spacer ring

Having unscrewed the mount, we disconnect the hub, brake disc and spacer ring - We remove the old grease inside the hub with a rag.

- To dismantle the outer race of the bearing, we fix the hub in a vice and knock out the ring with a beard.

Bearing cages are knocked out using a drill

Bearing cages are knocked out using a drill - We take out the clip.

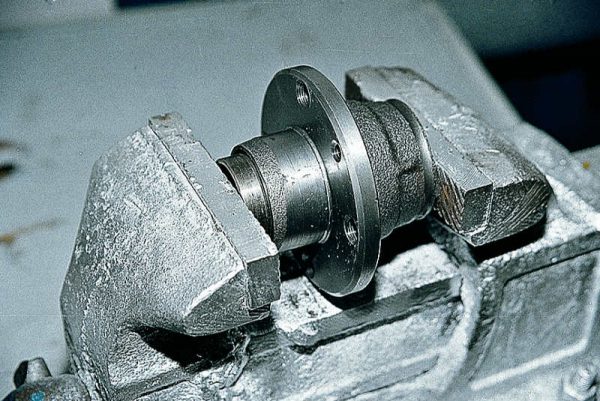

Removing the ring from the hub

Removing the ring from the hub - We pry off the oil seal with a flat screwdriver and remove it from the hub, and then we take out the remote sleeve located under it.

Pry off with a screwdriver and take out the seal

Pry off with a screwdriver and take out the seal - The bearing installed on the inner side of the hub is dismantled in the same way.

- To mount the outer races of new bearings, we use a vise and the same cages from old bearings as a guide.

In a yew we press in the clips of new bearings

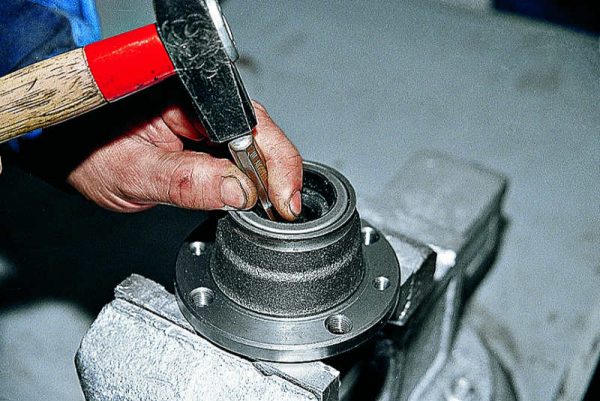

In a yew we press in the clips of new bearings - In the absence of a vice, a metal gasket, such as a chisel or hammer, can be used to press the rings.

Bearing rings can be pressed in with a hammer

Bearing rings can be pressed in with a hammer - We fill the Litol-24 grease with about 40 grams inside the hub and into the inner bearing separator.

We apply grease inside the hub and on the bearing itself

We apply grease inside the hub and on the bearing itself - We mount the inner bearing and spacer into the hub, after which we apply grease to the oil seal and press it in.

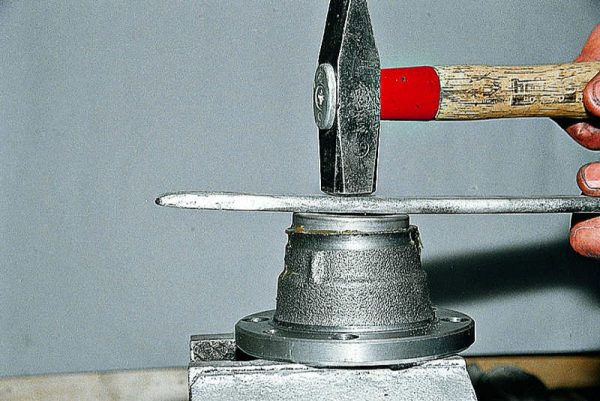

We press the gland with a hammer through a suitable spacer

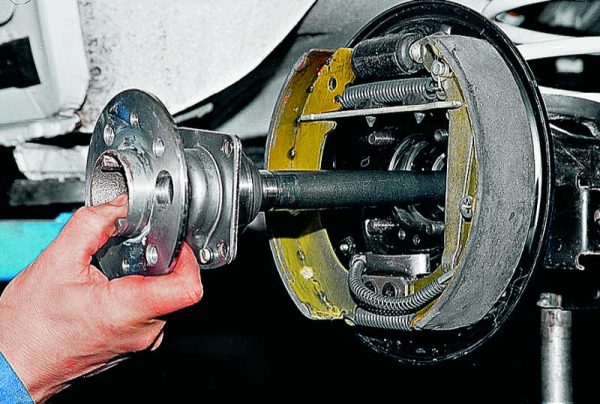

We press the gland with a hammer through a suitable spacer - We install the hub on the pin, avoiding damage to the lip seal.

- We apply grease and mount the inner part of the outer bearing, put the washer in place and tighten the hub nut.

- We adjust the clearance in the bearings and put a protective cap, stuffing it with grease.

Video: wheel bearing replacement

Watch this video on YouTube

Which to choose

Owners of the classic "Zhiguli" sooner or later, but have to deal with the replacement of hub bearings and the issue of choosing a manufacturer. Today there are many companies that produce products of this type. But it is better to give preference to such brands:

- SKF;

- SNR;

- SUBJECT;

- NTN;

- Learning;

- WHEN;

- NSK

The products of these manufacturers are characterized by high quality and meet the most stringent requirements.

If we consider domestic manufacturers of bearings, then those also exist. For AvtoVAZ, bearings are supplied by:

- CJSC LADA Image is a supplier of original Lada wheel bearings in the secondary market;

- SPZ (Saratov Bearing Plant);

- Volzhsky standard (Volzhsky plant);

- VBF (Vologda Bearing Plant);

- SPZ-9 (Samara plant).

Caliper

Considering the chassis of the VAZ "six", the brake caliper cannot be left without attention. This assembly is mounted on the steering knuckle, holds the brake pads and working brake cylinders through the appropriate holes, slots and grooves. There is a special hole in the caliper for the brake disc. Structurally, the product is made in the form of a monolithic steel part. When the piston of the working brake cylinder acts on the brake pad, the force is transferred to the brake disc, which leads to slowing down and stopping the car. In case of deformation of the caliper, which is possible with a strong impact, the brake pads wear unevenly, which significantly reduces their service life.

The caliper can receive damage of the following nature:

- the appearance of cracks. Since the part is constantly exposed to loads, cracks appear on it over time due to metal fatigue. This indicates the need to replace the caliper, since it is unsuitable for restoration;

- the formation of oxides on moving elements. The working cylinders gradually become covered with dirt and an oxide film, and the pistons begin to wedge over time, which reduces the braking efficiency. In this case, repair or replacement of the cylinders is required.

Semi-axle of the rear wheel VAZ 2106

On the VAZ 2106, the rear wheels are fastened by means of axle shafts. The part is fixed on the stocking of the rear axle and is its integral part, since it is the axle shaft that transmits rotation from the gearbox to the rear wheels.

The axle shaft is a reliable part that practically does not fail. The main element that sometimes needs to be replaced is the bearing.

With its help, uniform rotation of the considered node during movement is ensured. Bearing failures are similar to hub elements. When a part fails, the problem is solved by replacement.

Bearing replacement

To remove the axle shaft and replace the ball bearing, you need to prepare a certain set of tools:

- crank;

- head 17;

- a hammer;

- flat screwdriver;

- chisel;

- Bulgarian;

- new half shaft bearing with retaining ring;

- blowtorch or gas burner.

Removing the axle shaft

Dismantling is carried out in the following order:

- We raise the rear of the car from the desired side and remove the wheel, as well as the brake drum.

- To prevent leakage of grease from the rear axle beam, raise the edge of the stocking with a jack.

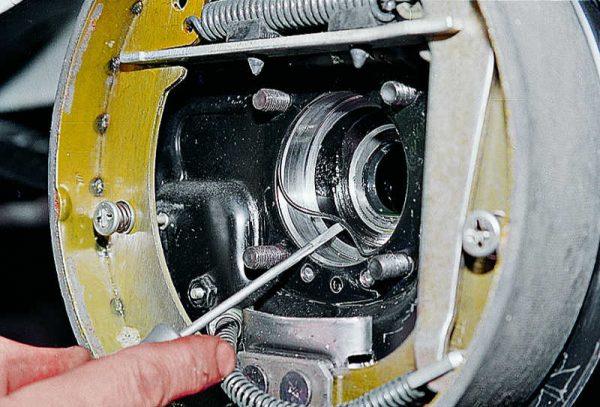

- With a 17-head collar, unscrew the axle shaft mount.

To remove the axle shaft, it is necessary to unscrew 4 nuts with a head of 17

To remove the axle shaft, it is necessary to unscrew 4 nuts with a head of 17 - We remove the engraving washers.

Unscrew the fasteners, remove the engraving washers

Unscrew the fasteners, remove the engraving washers - We mount the impact puller on the axle shaft flange and knock the axle shaft out of the stocking. For these purposes, you can use improvised means, for example, a wooden block and a hammer.

With the help of an impact puller, we knock out the axle shaft from the stocking of the rear axle

With the help of an impact puller, we knock out the axle shaft from the stocking of the rear axle - We dismantle the axle shaft together with the mounting plate, bearing and bushing.

The axle shaft is dismantled together with the bearing, mounting plate and bushing

The axle shaft is dismantled together with the bearing, mounting plate and bushing - Take out the seal.

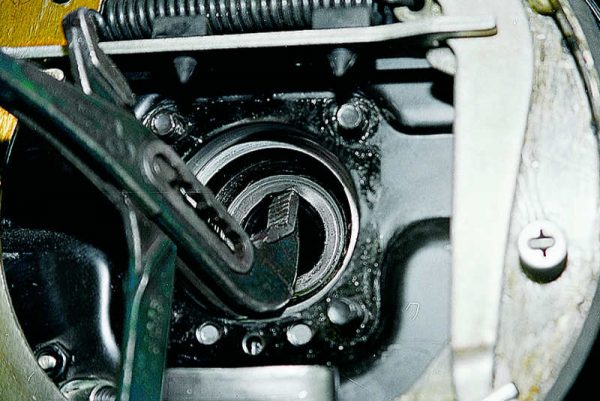

Screwdriver pry and remove the seal

Screwdriver pry and remove the seal - With the help of pliers, we take out the gland.

Using pliers, remove the axle shaft seal from the stocking

Using pliers, remove the axle shaft seal from the stocking

The brake pads do not interfere with the removal of the axle shaft, so they do not need to be touched.

Dismantling the bearing

The bearing removal process consists of the following steps:

- We fix the half shaft in a vice.

- We cut the ring with a grinder.

We cut the sleeve with a grinder

We cut the sleeve with a grinder - We split the ring with a hammer and a chisel, striking at the notch.

We break the sleeve with a hammer and chisel

We break the sleeve with a hammer and chisel - We knock the bearing off the axle shaft. If this fails, then with the help of a grinder we cut and split the outer clip, and then we dismantle the inner one.

We knock the bearing off the axle shaft, pointing a wooden block at it and striking with a hammer

We knock the bearing off the axle shaft, pointing a wooden block at it and striking with a hammer - We examine the condition of the semi-axis. If defects are found (deformation, signs of wear at the installation site of the bearing or splines), the axle shaft must be replaced.

After removing the bearing, it is imperative to check the axle shaft for damage and deformation.

After removing the bearing, it is imperative to check the axle shaft for damage and deformation.

Bearing installation

Install the new part as follows:

- We take out the boot from the new bearing.

Pry off with a screwdriver and remove the bearing boot

Pry off with a screwdriver and remove the bearing boot - We fill the bearing with Litol-24 grease or the like.

We fill the bearing with grease Litol-24 or similar

We fill the bearing with grease Litol-24 or similar - We put the duster in place.

- Apply grease to the bearing seat.

We also lubricate the bearing seat

We also lubricate the bearing seat - We mount the bearing with the boot outward, i.e., to the axle shaft flange, pushing it on with a suitable piece of pipe.

- We heat the sleeve with a blowtorch until a white coating appears on the part.

To make it easier to fit the ring on the axle shaft, it is heated with a gas burner or blowtorch

To make it easier to fit the ring on the axle shaft, it is heated with a gas burner or blowtorch - We take the ring with pliers or pliers and put it on the axle shaft.

- We install the sleeve close to the bearing, hammering it with a hammer.

- We are waiting for the ring to cool down.

When the sleeve is put on, let it cool down.

When the sleeve is put on, let it cool down. - We put a new oil seal and mount the axle shaft in its place. We assemble in the reverse order.

A new cuff is installed using a suitable adapter.

A new cuff is installed using a suitable adapter.

Video: replacing a semi-axial bearing on a "classic"

Watch this video on YouTube

Hubs with bearings and axle shafts of the VAZ 2106, although they are reliable elements, can still fail due to the constant exposure to high loads. The problem is mainly related to the wear of the bearings, which the owner of the Zhiguli can replace on his own. To work, you will need a little experience in car repair and a minimum set of tools, and in order to do everything right and avoid mistakes, you should first read the step-by-step instructions.