Reverse hammer: design, types, how to choose and use correctly

Content

Knowing what a reverse hammer looks like, you need to understand that it comes in different types. All tools have almost the same effect, with minor differences. Each of the hammers is used in certain cases to eliminate one or another type of damage.

Those who are engaged in body repair need to know what a reverse hammer is. This tool helps remove many types of dents and comes in several varieties.

The device and the principle of operation

The reverse hammer consists of a metal pin, a fastening device with a moving weight and a handle. The tool allows you to eliminate dents and other defects in body metal. To work, it must be attached to a damaged surface. This is done with a vacuum or glue, and some types of hammers have to be welded on. The use of any type of reverse hammer can effectively eliminate many iron defects. They must work carefully. Careless actions will not remove the damage, but worsen the condition of the metal.

The principle of operation of the reverse hammer is as follows:

- The tool fixed to the surface to be treated is held by the weight and the handle.

- Sharply bring the weight to the handle. In this case, you can feel the impact. But it is not done along the body, but in the opposite direction from it. By attaching the pin to the metal, the latter is stretched to the desired values.

Reverse hammer application

The tool is periodically moved along the dent so that it stretches evenly.

Types of hammers

Knowing what a reverse hammer looks like, you need to understand that it comes in different types. All tools have almost the same effect, with minor differences. Each of the hammers is used in certain cases to eliminate one or another type of damage. Some of the tools can be used for paintless removal of defects. But sometimes the reverse hammer has such a principle of operation that after it an update of the body coating will be required. This is especially true for straightening tools, which are attached to the iron by welding.

Vacuum Reverse Hammer

A vacuum hammer is called a reverse hammer, which is attached to the metal with a suction cup. A compressor is used to create a vacuum. For damage of different sizes and shapes, different types of suction cups are used.

Vacuum Reverse Hammer

Such a reverse hammer has a working principle that allows you to remove dents without damaging the varnish and paint. Therefore, they must be used with an intact paintwork.

Reverse hammer on a glued suction cup

The principle of operation of a reverse hammer on a glued suction cup is as follows:

- Fix the suction cup made of rubber with glue to the surface on which there are defects.

- Once the glue dries, attach the threaded pin to the suction cup.

- Pull out the dent in the usual way for this tool.

- Remove pin.

- Remove the suction cups, slightly heating the adhesive base with a hair dryer.

- Remove adhesive residue with solvent.

Reverse hammer with suction cups

Such a reverse hammer is used to remove defects without painting body parts. It is applied with a special adhesive and solvent that does not damage the paintwork of the machine.

Sometimes polishing may be required if there are scratches on the paint and varnish. And you can use such a tool only in warm weather or in a heated room. In the cold, glue is ineffective.

Reverse hammer with welding fixation

The reverse hammer, which has the name "with welding fixation", is used in the preparation of metal for painting. When attaching the tool to the surface, it will not be possible to avoid damaging the paint layer. To use it, you will need to first remove the primer and paint from the repaired surface. Before work, a nut is welded to the metal. Then you need to screw the hammer pin to it. They pull out the dent. At the end of the work, the nut is cut off, and the surface is primed and painted.

Reverse hammer with welding fixation

Knowing what a reverse hammer is that requires welding, many craftsmen now use it as a last resort. It is difficult to work with this tool, and its efficiency is not always high. Therefore, it is used only for complex injuries. But before, when there were no other types of tools for removing dents, you had to use only them.

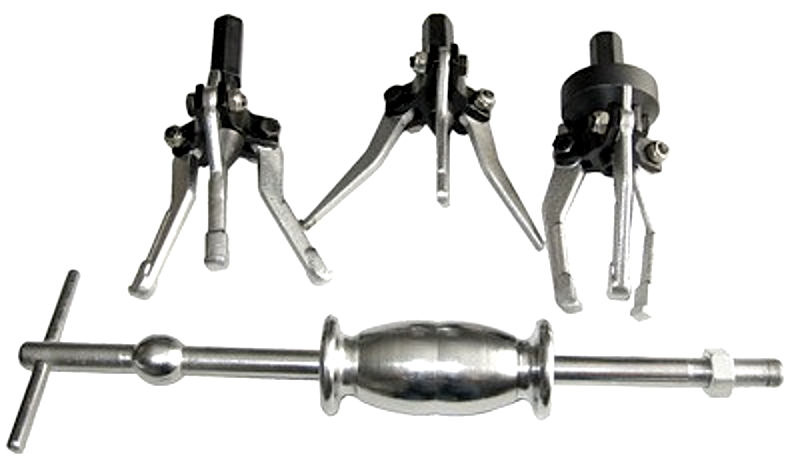

mechanical hammer

There is also a mechanical reverse hammer, which looks like a regular one. It is attached to the surface with hooks or clips. Its use on the car body is limited. The tool can be used where there is a place for fastening. Sometimes for this you have to cut a hole, which will then be welded. But this method is used very rarely.

Mechanical reverse hammer

Sometimes such a hammer is used to remove CV joints or bearings. It allows you to quickly remove the part with limited access to it and not damage it. The tool can be used for other repair work.

Advantages and disadvantages

Understanding what a reverse hammer is and how it works, it is important to know its strengths and weaknesses. It has many advantages:

- paintless dent removal

- work in inaccessible places;

- efficiency;

- cheapness;

- suitable for self-repair in the garage.

But such a technique and tools also have disadvantages. The main one is the inability to work without experience. In the absence of skills, there is a risk of damaging the surface more, and not correcting the defect. With such a tool, far from all the shortcomings of body iron can be eliminated. It is usually ineffective for severe damage.

How to choose

People who are constantly engaged in car body repair need to have all types of reverse hammers. You need to buy nozzles and suction cups of different sizes. This will allow you to eliminate dents of any kind and origin on body parts both by a paintless method and for subsequent coating.

Drivers who do such work occasionally can get by with hammers with vacuum or adhesive suction cups. A compressor is required to remove damage with a vacuum tool. And to manipulate the glue, you will need a solvent and a fastening agent. Such chemistry must be bought regularly and monitor the expiration date. It is desirable to have suction cups of different sizes. A tool with welding fixation is needed for those who are going to eliminate significant iron defects. To work with it, the skills of a painter may be required, since this method requires painting the element.

Working with reverse hammers is recommended in the garage. The technique requires experience. You should study on unnecessary metal objects.