Section: Pads, linings, brake shoes - The most common problems with drum systems

Patronage: Fomar. An efficient braking system is a basic piece of equipment for any vehicle and directly affects the safety of the user.

Patronage: Fomar. An efficient braking system is a basic piece of equipment for any vehicle and directly affects the safety of the user.

Department: Pads, linings, brake pads

Department: Pads, linings, brake pads

Patronage: Fomar

Most problems with drum systems are caused by improper preparation for changing the brake pads and improper installation of the pads on the brake pads. To minimize the risk of problems, avoid the following mistakes.

Wrong lining thickness

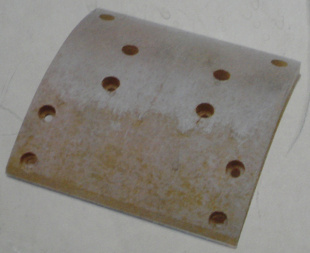

Don't forget to select the appropriate thickness of linings depending on the amount of wear on the drum. The discrepancy between these parameters leads to uneven wear of the linings (photo 1) and a decrease in braking efficiency (not the entire surface of the lining is adjacent to the surface of the drum).

The drum is not properly prepared for the new lining.

Before starting a drum with a new lining, it must be run in. The roller must adjust the radius of the drum to the outer radius of the lining and get a flat and smooth working surface, which is necessary for the correct operation of the friction pair. Incorrect surface preparation can lead to uneven and rapid wear of the linings, and most importantly, to a decrease in braking efficiency.

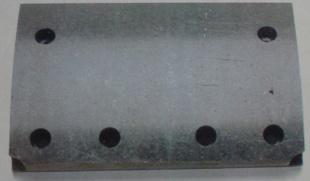

Attention! After rolling, do not forget to wash the drums with a degreaser. This action will remove the graphite layer from the surface, which precipitates during rolling. Failure to remove the resulting layer will lead to glazing of the lining surface (Photo 2) and, as a result, to a decrease in braking efficiency.

Incorrect placement of the jaw pad

The installation of pads on the jaw should be preceded by cleaning the contact surface. Any dirt accelerates the wear of the linings and contributes to a decrease in braking efficiency. In the worst case, contamination between the sponge and the liner can cause the liner to crack.

Another important issue is the choice of the appropriate diameter, length and head shape of the rivets used. Fomar products are supplied complete with a properly selected set of rivets. The choice of riveting devices also plays an important role. Incorrect rivet mandrel diameter can lead to cracking of the rivet flange (photo 3) or insufficient fit of the tongue to the jaw. In both cases, this leads to a loose connection of the lining to the cams and can lead to the breaking of the lining when braking.

Lack of periodic monitoring of the degree of wear of the linings

The use of pads below the wear threshold (photo 4) reduces braking efficiency and damages the drums.

By avoiding the mistakes mentioned above, we will positively influence the service life and efficiency of the entire braking system, thus contributing to the safety of vehicle users.