MAZ pressure regulator

The performance and reliability of the brake system of the car is the key to its safe operation. Therefore, the spare parts used in the repair and maintenance process must be of high quality. When operating MAZ trucks, it is recommended to install only original spare parts purchased from reliable suppliers.

Any MAZ vehicle initially has several brake systems: working, parking, spare, auxiliary. In addition, the brakes installed on the semi-trailer can be activated additionally.

Before buying a new truck in Khabarovsk or the Khabarovsk Territory, consult with the managers of the Transservice company who will help you choose a model of equipment according to your preferences and tasks!

Among the elements that directly affect the operation of the brake system is the pressure regulator, which maintains the optimum pressure in the pneumatic system of the car. At MAZ, the regulator also performs the function of a dehumidifier, removing moisture from the air injected into the system by the compressor. There may be several versions of the unit, for example, with heat output. Among other options, the presence or absence of an adsorber, the supply voltage of electric heating, etc.

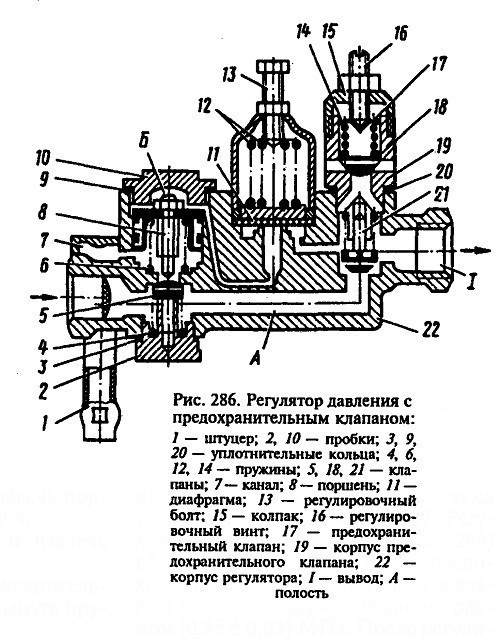

The use of regulators with an adsorber is necessary for vehicles in which the brake system operates at a pressure value in the range of 6,5-8 kgf / cm2. During operation, it periodically discharges air into the atmosphere, preventing the occurrence of excess pressure. When the unit is turned on, the pressure in the system is within 0,65 MPa, and when it is turned off, its value drops to 0,8 MPa.

It may interest you: functions and types of MAZ interior heaters

In cases of pressure increase up to 1,0-1,35 MPa, excess air is removed through the safety valve. The principle of operation of such a pressure regulator is extremely simple. Under standard conditions, the compressor draws air into the housing, from where it is directed through a check valve to the air cylinders.

The regulator was originally designed to work in harsh conditions, so it can remain operational at low temperatures down to -45 degrees and at a temperature of 80 degrees. The rated power of the device is 125 watts. Most models operate on 24 V, but there are also versions designed for 12 V. The heater (if any) is connected to the operation at a temperature below +7 degrees and is turned off when the temperature reaches +35 degrees.

Causes of failure of the pressure regulator?

If an element deviates from the optimal mode of operation, it is necessary to check it with subsequent repair or replacement.

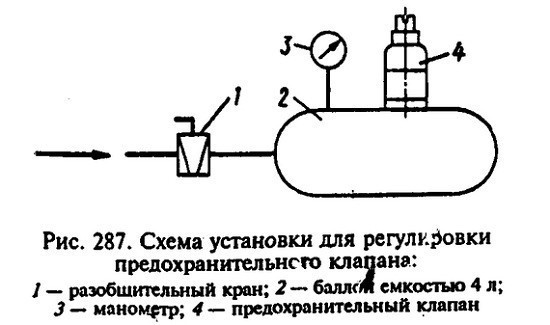

The functioning of the part is associated with the need for periodic adjustments. This is necessary not only to change the regulator or its individual parts, but also for any operations related to the replacement of spare parts for the car's pneumatic system. It is also desirable to conduct inspections on a regular basis to allow early detection of problems.

You can do it like this:

- Give the adjusting bolt to reduce the pressure to a minimum. Some regulators require the use of an adjustment cap over the spring. When the bolt is screwed in, there is a constant increase in pressure due to a decrease in internal volume.

- Increasing pressure to maximum values is achieved by increasing the number of gaskets used. They are located under the valve spring.

When making adjustments, it is necessary to rely on the manufacturer's recommendations, and also constantly monitor the change in pressure indicators on the dashboard of the machine, where there is an appropriate pressure gauge.

It's interesting - a comparison of MAZ and KAMAZ cars

In the process of checking and adjusting, it is also necessary to take into account the intensity of the connection with the operation of the compressor. In most cases, the cessation of their work can be noticed by a characteristic hissing sound.

Despite the fact that very reliable pressure regulators with a long service life are installed on MAZ vehicles, they are not 100% protected from the occurrence of certain failures. Most often they are associated with:

- Clogged air ducts.

- Wear of individual elements.

- Broken springs.

- Worn out filters.

Any of the above malfunctions causes failures that accompany the operation of the regulator with an adsorber. In some cases, significant pressure drops can be observed in the pneumatic system, which are practically impossible to adjust. Over time, this leads to the failure of not only the regulator, but the entire pneumatic system, which is affected by high pressure.

To help the driver: tips for adjusting MAZ valves

If an element deviates from the optimal mode of operation, it is necessary to check it with subsequent repair or replacement.