We pump the clutch on the VAZ 2106 on our own

Content

If the clutch fails, the car will not even be able to move. This rule is also true for the VAZ 2106. The clutch on this car has never been particularly reliable. And if you remember how complicated the clutch is on the "six", it becomes clear why it is a constant source of headaches for the car owner. Fortunately, most clutch problems are solved by simply bleeding the system. Let's figure out how this is done.

Appointment of the clutch on the VAZ 2106

The main task of the clutch is to connect the engine and transmission, thereby transferring torque from the engine to the driving wheels of the car.

The connection of the motor and transmission occurs when the driver, having started the engine, presses the clutch pedal, then turns on the first speed, and then smoothly releases the pedal. Without these mandatory actions, the car simply will not budge.

How the clutch works

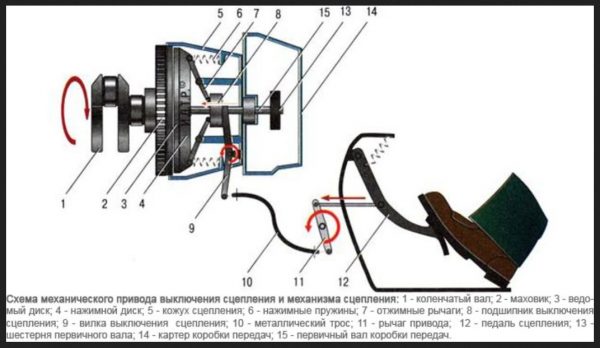

The clutch on the VAZ 2106 is a dry type. The main element of this system is the driven disk, which operates constantly in a closed cycle mode. In the center of the driven disk there is a spring pressure device to which the vibration damping system is attached. All these systems are placed in a non-separable metal case, fixed to the engine flywheel using special long pins.

The torque from the engine to the transmission is transmitted due to the action of the friction force on the driven disk. Before the driver presses the clutch pedal, this disc in the system is tightly clamped between the flywheel and the pressure plate. After gently pressing the pedal, the clutch lever begins to turn under the influence of hydraulic fluid and displaces the clutch fork, which, in turn, begins to put pressure on the release bearing. This bearing moves closer to the flywheel and puts pressure on a series of plates that push the pressure plate back.

As a result of all these operations, the driven disk is released, after which the driver is able to turn on the desired speed and release the clutch pedal. As soon as he does this, the driven disk will again be sandwiched between the flywheel and the pressure plate until the next gear change.

About the clutch master and slave cylinders

To move the levers in the VAZ 2106 clutch system, not cables are used, but hydraulics. This is a feature of all classic VAZ models, from the "penny" to the "seven" inclusive. The hydraulics of the clutch system on the "six" consists of three main elements: the master cylinder, the slave cylinder and hoses. Let's consider each element in more detail.

About the clutch master cylinder

The clutch master cylinder is located directly under the brake fluid reservoir, so it is easy to get to if necessary. It is the master cylinder that creates excess pressure in the entire hydraulic system of the car after the driver depresses the pedal. Due to the increase in pressure, the slave cylinder is turned on, transmitting force directly to the clutch discs.

About the clutch slave cylinder

The slave cylinder is the second most important element of the hydraulic clutch system on the VAZ 2106. As soon as the driver presses the pedal and the master cylinder increases the overall pressure level in the hydraulics, the pressure in the slave cylinder also changes abruptly.

Its piston extends and presses on the clutch fork. After that, the mechanism starts the sequence of processes mentioned above.

Clutch Hoses

The third most important element of the clutch hydraulic drive is high-pressure hoses, without which the operation of the system is simply impossible. On early XNUMXs, these hoses were all metal. On later models, reinforced hoses made of high-strength rubber began to be installed. These hoses had the advantage of being able to withstand high pressures while being flexible, making changing them much easier.

But there was also a serious drawback: despite the high reliability, reinforced hoses still wore out faster than metal ones. Neither reinforced nor metal clutch hoses can be repaired. And in the event of a brake fluid leak, the driver will have to change them.

Common clutch malfunctions VAZ 2106

Since the clutch on the "six" has never been reliable, car owners regularly encounter malfunctions of this system. All these breakdowns are divided into several categories, and the causes of breakdowns are well known. Let's list them.

The clutch is not completely disengaged

Drivers simply refer to partial disengagement of the clutch as "clutch leads." Here's why it happens:

- the gaps in the clutch drive have increased greatly due to wear. If during inspection it turns out that the parts in the drive are not too worn out, then the gaps can be adjusted using special bolts;

- driven disk is bent. If the end runout of the driven disc exceeds one millimeter, then the driver has two options: either try to straighten the driven disc with locksmith tools, or replace it with a new one;

- cracked friction linings. Friction linings are attached to the surface of the driven disk. Over time, they may crack. In addition, their surface initially may not be too smooth. All this leads to the fact that the clutch cannot be switched off in a timely manner. The solution is obvious: either a set of linings or the entire driven disk should be changed;

One of the friction linings was completely worn out and broke away from the disc

One of the friction linings was completely worn out and broke away from the disc - rivets on friction linings broke. Even if the friction linings are even, the fastening rivets may wear out over time. As a result, the lining begins to dangle, which creates problems when disengaging the clutch. The lining itself wears out a lot. So even if we are talking about one broken lining, the driver will have to change the set of linings completely. And after that, he should definitely check the end runout of the driven disk so that the problem does not arise again;

When the pads are worn, it is easier to install a new disc than to replace them.

When the pads are worn, it is easier to install a new disc than to replace them. - the hub of the driven disk periodically jams. As a result, the hub cannot leave the spline on the input shaft in a timely manner, and the driver cannot engage the desired gear in a timely manner. Solution: carefully inspect the input shaft splines for dirt, rust and mechanical wear. If dirt and rust are found, the slots must be thoroughly cleaned with fine sandpaper, and then LSC 15 should be applied to them, which will prevent further corrosion. If the splines are completely worn out, there is only one option: replacing the input shaft;

When the input shaft is worn, it is simply replaced with a new one.

When the input shaft is worn, it is simply replaced with a new one. - broken plates on the thrust flange of the casing. These plates are not replaceable. If they break, you will have to completely change the clutch cover, which comes complete with thrust plates;

- air got into the hydraulics. This is one of the most common reasons why the clutch begins to “lead”. The solution is obvious: the hydraulics will have to be pumped;

- the pressure plate is skewed. This happens very rarely, but nevertheless it is impossible not to mention this breakdown. If it turns out that the pressure plate is skewed, you will have to buy a new clutch cover with the disc. It is not possible to eliminate such a breakdown on our own;

- loosened rivets on the pressure spring. These rivets are the weakest point in the VAZ 2106 clutch system, and the driver should constantly monitor their condition. If the pressure spring began to dangle noticeably, there is only one solution: buying and installing a new clutch cover with a new release spring in the kit.

Spring rivets were always made of copper and were not very durable.

Spring rivets were always made of copper and were not very durable.

Brake fluid leaks

Since the clutch on the "six" is equipped with a hydraulic drive, this entire system is activated using conventional brake fluid. This feature of the "six" clutch leads to several serious problems. Here they are:

- brake fluid leaking through a damaged hose. Typically, fluid begins to flow out through loose pipe connections. In this case, it is enough to simply tighten the desired nut or clamp, and the problem will go away. But it also happens differently: a hydraulic hose can break both due to external mechanical stress and due to cracking due to old age. In this case, the damaged hose will have to be replaced (and since clutch hoses are only sold in sets, it is worth changing other old hoses on the car, even if they are not damaged);

Fluid can escape unnoticed through these small cracks.

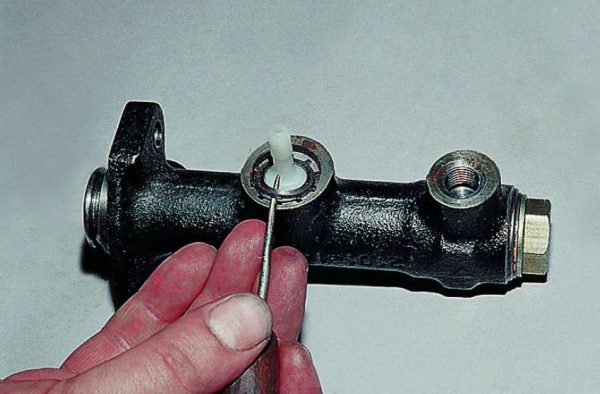

Fluid can escape unnoticed through these small cracks. - fluid leaking through the master cylinder. The clutch master cylinder has sealing rings, which eventually become unusable and lose their tightness. As a result, the brake fluid gradually leaves the system, and its level in the reservoir is constantly decreasing. Solution: change the sealing rings on the cylinder (or change the cylinder completely), and then bleed the hydraulic system;

Repair kit for sealing rings for the master cylinder "six"

Repair kit for sealing rings for the master cylinder "six" - blockage of the hole in the cap of the brake fluid reservoir. If the hole is clogged with something, then when the brake fluid level drops, a discharged space appears in the reservoir. Then a vacuum also occurs in the master cylinder, as a result of which external air is sucked in through the seals, even if they were previously sealed. After discharge, the tightness of the gaskets disappears completely, and the liquid quickly leaves the tank. Solution: clean the brake reservoir cap, replace the damaged gaskets in the cylinder and add brake fluid to the reservoir.

The liquid is added to the tank up to the upper edge of the horizontal metal strip

The liquid is added to the tank up to the upper edge of the horizontal metal strip

Clutch "slips"

“Slippage” of the clutch is another failure option in which this system does not work completely. Here's why it's happening:

- friction linings burned to the driven disk. Most often this happens through the fault of the driver, who never got rid of the bad habit of holding the clutch pedal depressed for a long time. It is not advisable to change burnt linings. It's best to just buy a new clutch cover with new pads and install it in place of the old one;

- the expansion hole in the master cylinder is clogged. This phenomenon also leads to intense “slipping” of the clutch when changing gears. Solution: remove the cylinder and carefully clean the expansion hole, and then wash the cylinder in kerosene;

- friction linings on the driven disk are oily. Solution: all oily surfaces are carefully wiped with a sponge dipped in white spirit, and then wiped with a dry sponge. Usually this is enough to eliminate the "slipping" of the clutch.

The arrows show the contaminated areas on the driven disk

The arrows show the contaminated areas on the driven disk

Noise when releasing the clutch pedal

A malfunction that is characteristic, perhaps, only for the clutch of "sixes": when the pedal is released, the driver hears a characteristic hum, which over time can develop into a loud rattle. Here are the reasons for this phenomenon:

- The clutch bearing is completely worn out. Any part eventually becomes unusable, and the bearings in the "six" clutch are no exception. Most often they break after the lubricant leaves them. The fact is that the side seals of these bearings have never been particularly tight. And as soon as all the grease is squeezed out of the bearing, its destruction becomes only a matter of time. There is only one solution: replacing the bearing with a new one, since it is impossible to repair this critical part in a garage;

When this bearing wears out, it makes a lot of noise.

When this bearing wears out, it makes a lot of noise. - failure of the bearing on the input shaft of the gearbox. The reason is the same: grease was squeezed out of the bearing and it broke, after which the driver began to hear a characteristic crack when the clutch was released. To eliminate the cod, the primary bearing will have to be replaced.

Noise when pressing the clutch pedal

In some situations, the driver may hear a characteristic low hum when pressing the clutch pedal. As soon as the driver releases the pedal, the noise disappears. This happens for this reason:

- damper springs on the driven disk have lost their former elasticity. As a result, the vibration of the driven disk cannot be extinguished in a timely manner, which leads to the appearance of a characteristic hum, from which the entire interior of the car shudders. Another option is also possible: one or more damper springs simply break. If this is what happened, the hum is accompanied by a very loud rattle. There is only one solution: a complete replacement of the clutch cover along with damper springs;

Damper springs are responsible for damping vibrations of the driven disk of the "six"

Damper springs are responsible for damping vibrations of the driven disk of the "six" - the return spring on the clutch fork has fallen off. Also, this spring can stretch or break. In all cases, the driver will hear a rattle immediately after pressing the clutch pedal. Solution: Replace the return spring on the fork with a new one (these springs are sold separately).

Springs for clutch forks "six" are sold separately

Springs for clutch forks "six" are sold separately

Clutch pedal fails

Sometimes the driver of the "six" is faced with a situation where the clutch pedal, after being pressed, does not return to its original position on its own. There are several reasons for this failure:

- the clutch pedal cable broke at the tip. It will have to be replaced, and it is not so easy to do this in a garage: on the “six” this cable is located in a very inaccessible place. Therefore, it is best for a novice driver to seek help from a qualified auto mechanic;

The clutch pedal cable cannot be replaced without the help of an auto mechanic.

The clutch pedal cable cannot be replaced without the help of an auto mechanic. - The clutch pedal return spring has failed. A second option is also possible: the return spring has broken (although this happens extremely rarely). The solution is obvious: the return spring will have to be replaced;

The clutch pedal of the "six" practically lies on the floor of the cabin

The clutch pedal of the "six" practically lies on the floor of the cabin - air got into the hydraulics. This can also cause the clutch pedal to fall to the floor. But the pedal will not fail all the time, but after several clicks. If such a picture is observed, then the clutch system should be bled as soon as possible, having previously eliminated the places of air leakage.

Video: why the clutch pedal falls

About brake fluid for VAZ 2106

As mentioned above, the "six" clutch is actuated by a hydraulic actuator running on conventional brake fluid. This fluid is poured into the brake reservoir, installed in the engine compartment, to the right of the engine. The operating instructions for the "six" indicate the exact volume of brake fluid in the system: 0.55 liters. But experienced owners of "sixes" recommend filling in a little more - 0.6 liters, as they remember that sooner or later the clutch will have to be pumped, and a small leak of fluid is inevitable.

Brake fluid is divided into several classes. In our country, DOT4 class liquid is the most popular among drivers of "sixes". The basis of the liquid is ethylene glycol, which includes a set of additives that significantly increase the boiling point of the liquid and lower its viscosity.

Video: adding brake fluid to the "classic"

Watch this video on YouTube

The sequence of bleeding the clutch on the VAZ 2106

If air has entered the clutch hydraulic drive system, then there is only one way to remove it - to bleed the clutch. But you need to decide on the tools and consumables necessary for this procedure. Here they are:

- spanner key for 8;

- plastic bottle for draining old brake fluid;

- a bottle with a new DOT4 class brake fluid;

- a piece of transparent silicone tube 30 cm long and 5 mm in diameter;

- rags.

Sequence of pumping

First of all, it should be noted that the main condition for successful clutch bleeding is placing the machine in an inspection pit. Alternatively, you can drive the "six" to the overpass. In addition, you will need the help of a partner to do this job. It is extremely difficult to bleed the clutch without a pit and a partner, and only an experienced car owner can cope with this task.

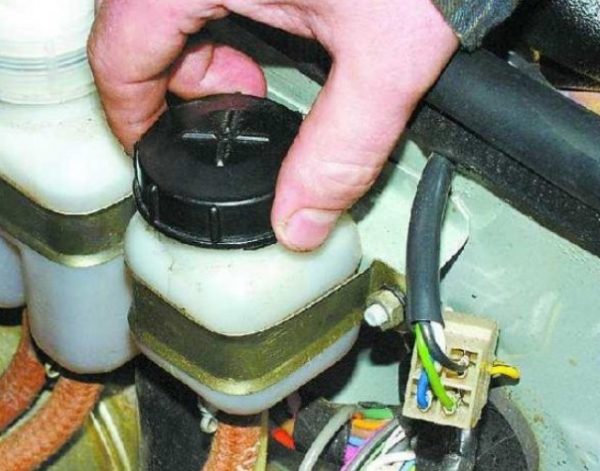

- The hood of the car in the pit opens. The brake reservoir is cleaned of dirt. Then the liquid level is checked in it. If necessary, the liquid is topped up (up to the upper border of the horizontal metal strip).

Before starting bleeding, it is better to open the brake reservoir cap

Before starting bleeding, it is better to open the brake reservoir cap - Now you should go down to the observation hole. The clutch slave cylinder has a small nipple covered with a cap. The cap is removed, the fitting is unscrewed a couple of turns using an 8 key. A silicone tube is inserted into the opened hole, the other end of which is lowered into a plastic bottle.

The other end of the silicone tube is dipped into the bottle

The other end of the silicone tube is dipped into the bottle - The partner sitting in the cab presses the clutch pedal 5 times. After the fifth press, he keeps the pedal depressed to the floor.

- The union is unscrewed by another 2-3 turns. After that, the brake fluid will begin to flow out of the tube directly into the bottle. Air bubbles will be clearly visible in the escaping liquid. When the brake fluid stops bubbling, the tube is removed and the fitting is screwed into place.

The liquid coming out of the bottle will definitely bubble

The liquid coming out of the bottle will definitely bubble - After that, a small portion of fluid is again added to the brake reservoir and all of the above steps are repeated.

- The bleeding procedure must be repeated until a clean, bubble-free brake fluid comes out of the fitting. If the car owner managed to achieve this, then the pumping can be considered complete.

Video: pumping the clutch without an assistant

Watch this video on YouTube

Why the clutch is not pumping

There are situations when it is not possible to bleed the clutch. This can happen for the following reasons:

- clogged hole in the brake reservoir. This has already been discussed above. However, the lack of air access to the reservoir can lead not only to problems with the master cylinder, but also to the inability to properly bleed the clutch. The brake fluid leaving the bottle will always bubble as air will constantly enter the system through the leaky seals. Therefore, it is best to slightly unscrew the brake reservoir cap before bleeding the clutch;

- the union on the slave cylinder is not completely unscrewed. These fittings on "sixes" over time strongly oxidize and rust. It often takes a lot of effort to unscrew them. If the car owner did not make a couple of extra revolutions, the oxidized fitting may simply not let the brake fluid into the bottle, canceling out all attempts at pumping. So if the partner presses the pedal, and the liquid does not go into the bottle, it makes sense to unscrew the fitting a few more turns.

So, bleeding the clutch is a task that is quite within the power of even a novice car enthusiast. It does not require any special skills or a lot of experience. All you need to do is follow the above recommendations exactly.