Ball joint and signs of its malfunction

Content

How important is the ball joint

The ball joint requires special attention, this is one of the many reasons that once and for all will force a person who believes that he controls everything to observe the speed limit and pay due attention to his car.

The pivot device has been replaced by the main suspension element, which is called the ball joint. When worn to a critical point, some car models have serious problems. How to determine the malfunction of the patella, read on.

The ball joint is the joint that connects the steering wheel hub and suspension arm. Its task is to ensure the possibility of turning the hub with the initial position of the wheel horizontally during vertical movement.

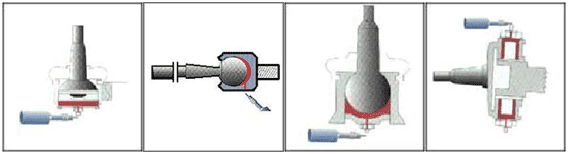

The design of the ball joint is very simple. It is a cone-shaped finger with a mushroom-shaped or spherical tip, which can rotate and simultaneously swing at an angle on the supporting body. The housing is pressed against the lever or screwed. In this case, the ball joint, as a rule, changes along with the suspension arm.

In the newly introduced modern nodes, a non-separable design is mainly used. In it, after installing the finger, the body tends to roll up. Plastic or other inserts are placed between the body and the finger. They function as a plain bearing and provide effortless rotation. For old domestic models of machines, other ball bearings are also supplied, which are called collapsible. The backlash in them is removed by tightening the cover.

Causes of ball joint breakage

During operation, these supports experience significant loads. Depending on where they are installed and the design of the suspension, the mounts support most of the total vehicle weight, and also withstand constant, systematic shocks when driving on rough roads.

The main reason for the malfunction of the ball joint is the wear of the contact surfaces, which leads to an increase in the gap between the body and the pin. As a result, the finger begins not only to twist, but also to hang on the body.

If wear is too severe, loads on the bearing can cause the pin to come out of the housing. As a result of all this, it turns out that the mechanism is not able to hold the steering wheel and the car falls on the asphalt.

The increase in clearance occurs due to the following factors:

- 1. Natural wear combined with obsolete materials: on average, a ball joint can travel between 20 and 000 kilometers. However, if the part is more or less of high quality, problems can begin after about 150 thousand kilometers by car. Wear is influenced by many factors: the quality of the manufactured part, operating conditions, care of the part, the presence of lubrication, the integrity of the anther.

- 2. Increasing dynamic loads while driving: This mainly refers to driving a car at high speed on a rough road. Under such conditions, impacts fall on various suspension elements, including the ball joint. Naturally, this leads to their wear and damage.

- 3. The protective cover or case is broken; as a result, water and all kinds of dirt enter the gap and, over time, increase corrosion and even abrasive wear. If the anther breaks, moisture, sand, dirt, and small debris will definitely get inside while the car is moving. All these elements form an abrasive material that naturally wears out your interior.

- 4 lack of lubrication on the hinge (if necessary, its presence) - the lubricant is removed from the ball joint for natural reasons - drying, evaporation. As mentioned above, if the boot is damaged, the grease can be removed very quickly due to natural causes, which will lead to more wear on the ball joint. Therefore, it is useful to periodically add a lubricating mass to the ball.

Here are some of the main signs of wear:

- When driving on a rough road at low speed, a knock is heard.

- If the effort on the steering wheel is increased, and when turning, a creak is heard from the front of the car.

- Because the front wheels wobble, your car is moving in a straight line unsteadily.

- Tires are worn unevenly.

Symptoms and causes of malfunction

| Symptoms | Description and reasons |

| Knocking steering wheel while driving | Strange sounds will appear at any speed, clearly noticeable when hitting a pothole, pit, etc. This is repeated once. |

| Change in composition | The wheel with a faulty ball joint suffers the most. Tire edge wear may increase. |

| The car rolls down the road | There is play in the ball joint, so the wheel wobbles when driving. |

| Crack during maneuvers | Creaks can come from the steering wheel, rear wheels, you need to listen specifically to the front ones, and when maneuvering. |

| Change braking path | The car will be demolished in the direction where there is a faulty ball joint. |

| Uneven tire wear | When, as a result of damage to the ball joint, the steering wheel is not strictly vertical, but at an angle to the roadway, the tread wears out more along its inner edge (closest to the engine) than along the rest of the wheel surface. |

How to determine the malfunction of the ball

Unfortunately, the condition of the media cannot always be determined using media designed to diagnose outboard drives. You can assess your condition using the usual old methods: by touch and by ear.

Method number 1 When performing a hearing test, you need to shake the car and listen to what exactly is knocking in it.

Method No. 2 To avoid errors as a result of diagnostics, with the brake pedal depressed to the end (to eliminate bearing play), the wheel must be shaken by hand. To do this, you need to take it at the highest and lowest points. If play is still felt, be aware that there is a gap in the mount and it needs to be replaced. But to determine the amount of wear, it would be best to use the most accurate fixtures and fittings, for example, a mount or a jack.

In the classic model of a VAZ car, there is a special control hole located in the design of the lower ball joint. For diagnosis, use a feeler gauge or depth gauge to measure the distance between the end of the ball stud and the outer surface of the housing through this inspection hole under load. For VAZ cars, the figure will be no more than 11,8 millimeters (for original mounts).

In the upper grid, the game can be measured with a specialized device with an indicator. The gap should not exceed 0,8 mm.

In the event that you do not have specialized tools, fixtures and an elevator at hand, you can put your palm on the body of the patella to touch the body and finger at the same time. Ask a partner to move the wheel. If there is a backlash, then, as a rule, it is felt.

Ball joint repair

There are several ways to repair. Often the patella is replaced with a new one. Replacing the bracket along with the lever for most foreign cars is very expensive, since the price of one lever is not a small amount, but there are also cars that have complex multi-link suspensions (up to 5 on one side). The cost of the work done will also be quite high for the lower lever and double for the upper one. Therefore, the services of restorers who repair even those supports that change as an assembly with a lever are in great demand.

Restoring is much cheaper than buying a new part. This is especially noticeable for the mounts that come complete with levers. Various technologies can be used to restore them.

- The easiest way is to convert it into a collapsible design, change the plastic inserts and polish the finger.

- Somewhat laborious technology: the body is filled with liquid polymer under pressure. Also, this polymer hardens in voids. The fasteners pressed into the arms are first removed and then replaced with non-original fasteners.

There are times when it simply rests on the lever, i.e. you don’t need to press it, if you decide to leave the ball joint like this, then it will hit the lever and its resource will be reduced many times, this can be solved by welding, i.e. it hooks onto the lever pointwise for 6-8 welding points.

Remember that such savings may cause problems in the future, in order to avoid this, it is recommended to still use new nodes.

the sound of the rails the swaying of the wagon the sound is audible for the timely elimination of the period of operation the sound phenomena for the visual diagnosis of crack protection

What is the resource of the ball joint

The service life depends mainly on various factors, it can range from 15 to 120 thousand kilometers.

Dramatically reduces the "life" of even a small crack in the anther. This can cause water, dirt and sand to enter the joint. In order to avoid damage, it is necessary to monitor the condition of the protective rubber boot. It is best to do this on a flyover.

To make it last longer, you need to drive more carefully on broken roads, as well as replace damaged anthers in a timely manner.

Is it possible to drive with a broken ball

It all depends on the degree of wear and damage to the specified node. If a knock in the movable ball joint has just appeared and the car is not yet “driving” along the road, it is not beating in corners, that is, there are only early signs, then you can still move around in that car.

However, make sure that the driving speed is not high, and also try to avoid potholes and bumps. And of course, you still need to think about the upcoming repairs. After all, the sooner this is done, the better, firstly, it will cost less, and secondly, the car can be operated safely!

If the breakdown of the ball joint has already reached such an extent that the car “rides” along the road and the knock of the movable ball joint is clearly audible, then it is better to refuse to operate such a car until the repair is completed. In extreme cases, you can drive it to a car service or garage at low speed and following the rules of safe driving, where it should be replaced.