SHRUS-4 grease for axle shafts

Content

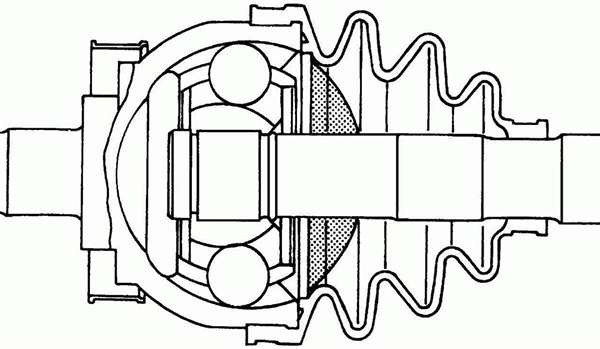

What is a constant velocity joint (CV joint)? From a mechanical point of view, this is a bearing with a reduced number of balls. As a rule, there are three on small cars and six on large transmissions.

The fundamental difference from a conventional ball bearing lies in the operating conditions. Open body, free movement of clips relative to each other, different ratio of balls and clips diameters.

Therefore, the maintenance of these units is different from the maintenance of classic bearings. Traditionally, SHRUS 4 grease or similar compounds are used.

This consumable was developed specifically for the automotive industry, the article corresponds to TU 38 201312-81. This type of grease is placed on the conveyor shaft and is offered for sale free of charge for routine maintenance.

Characteristics and application of SHRUS lubricant on the example of different mechanisms

Why is ordinary liquid oil not suitable for CV joints, for example, in gearboxes or transfer cases? The design of the hinge does not allow filling this assembly with grease even halfway.

There is no crankcase, the outer shell is a rubber or composite case. Clamps provide tightness, and the oil will simply flow out under the action of centrifugal force.

Although there is liquid oil in the gearbox (or rear axle gearbox), its crankcase and the CV joint cavity do not communicate with each other. Therefore, mixing lubricants is excluded.

Loop types:

- ball - the most common and versatile design;

- The tripoid CV joint is used on domestic (and some foreign) cars from the inside, where the breakage of the hinge is minimal;

- biscuits are used in trucks - they are characterized by high torque and low angular speed;

- cam joints "digest" a monstrous torque and operate at low speeds;

- CV joint replacement - double cardan shaft (lubrication only inside the cross members).

During operation, the angles of crossing the shafts can reach 70°. Lubrication specifications must be sufficient to ensure proper operation of the joint.

- reduction of the coefficient of friction on the contact surfaces;

- increased wear resistance of the hinge;

- due to anti-friction additives, mechanical losses inside the assembly are minimized;

- non-stick properties (perhaps the most important characteristic) - a wear indicator of at least 550 N;

- protection of steel parts of the CV joint from internal corrosion;

- zero hygroscopicity - with a temperature difference, condensate may form, which does not dissolve in the lubricant;

- water-repellent properties (from the penetration of moisture through damaged anthers);

- chemical neutrality with respect to rubber and plastic parts;

- durability of use (lubrication change is associated with a large amount of work);

- neutralization of the abrasive properties of dust and sand entering the hinge (for obvious reasons, an oil filter cannot be used);

- wide temperature range: from -40°С (ambient air temperature) to +150°С (normal CV joint heating temperature);

- high dropping point;

- strong adhesion, allowing the lubricant to be retained on the surface under the action of centrifugal spraying;

- preservation of inherent characteristics during short-term overheating and return of viscosity indicators after cooling to operating temperature (welding load of at least 4900N and critical load of at least 1090N);

For an internal CV joint, the characteristics may be less demanding, but in general, the same composition is laid in both "grenades". It's just that the outer CV joint requires more frequent oil changes.

Varieties of greases for hinges

SHRUS 4 grease has long become a household name, although the composition of different manufacturers is different.

SHRUS 4M

The most popular CV joint lubricant with molybdenum disulfide (actually GOST or TU CV joint 4M). This additive provides excellent anti-corrosion properties due to the presence of acid-neutralizing metal salts.

This property is especially useful when the anther seal is lost. It is easy to notice a clear break, but the loosening of the clamp is practically not diagnosed. However, the lubricant itself begins to lose its properties when moisture enters.

Molybdenum disulfide does not corrode rubber or plastics and does not react with non-ferrous metals.

Important: Information that molybdenum restores a worn layer of metal or “heals” traces of shells and balls is nothing more than an advertising fraud. Worn and damaged hinge parts are only repaired mechanically or replaced with new ones.

The notorious Suprotec CV joint grease simply restores a smooth surface, no new metal builds up. Grease with molybdenum additives tolerates low temperatures well. Even at -50°C, the hinge turns reliably and does not stick due to thickened oil.

barium additives

The most durable and technologically advanced. There are many imported (expensive) options, but for budget drivers there is a domestic option: SHRUS grease for a SHRB-4 tripod

This advanced composition, in principle, is not afraid of moisture. Even if liquid enters through a damaged bushing, the properties of the lubricant will not deteriorate and the metal of the hinge will not corrode. Chemical neutrality is also at a high level: the anthers do not tan and do not swell.

The only problem with barium additives is the quality degradation at low temperatures. Therefore, in the conditions of the Far North, the application is limited. For the central rail during short-term frosts, it is recommended to warm up the loop at low speeds. For example, maneuvering in a parking lot.

Lithium greases

The oldest version that came with SHRUS. Lithium soap is used to thicken the base oil. Works well at medium and high temperatures, has strong adhesion.

Quickly restores performance after a short overheat. However, at negative temperatures, the viscosity increases sharply, up to the paraffin state. Consequently, the working layer is torn, and the hinge begins to wear out.

Is it possible to lubricate the CV joint with lithol?

Trying to understand which lubricant is best for CV joints in the central rail, drivers pay attention to Litol-24. Despite the addition of lithium, this composition is not suitable for CV joints.

The only way out (given accessibility) is to “stuff” the assembly after replacing the broken anther and continue the repair on site. Then flush the gasket and fill it with the appropriate lubricant.

To determine which lubricant is better to use for CV joints, I recommend watching this video

The principle “you can’t spoil porridge with oil” does not work in this case. There is no information on how much lubricant is needed in the CV joint in the technical documentation of the car. The principle is as follows:

- the hinge cavity is completely filled with grease, without the formation of air bubbles;

- then the part of the assembly, which is closed with anther, is closed;

- anther is put on and slightly twisted by hand: excess fat is squeezed out along the axis of the rod;

- after removing them, you can crimp the clamps.

“Excess” fat when the hinge is heated can crack the anther.