The device and features of the torsion bar suspension of the car

Content

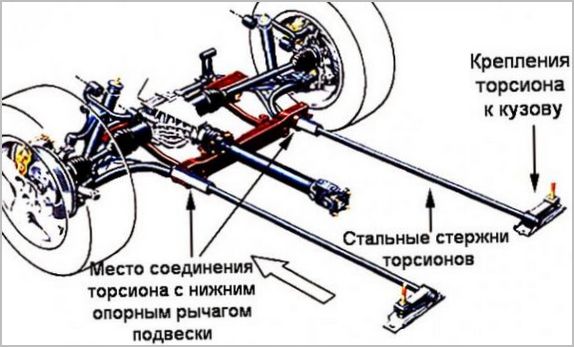

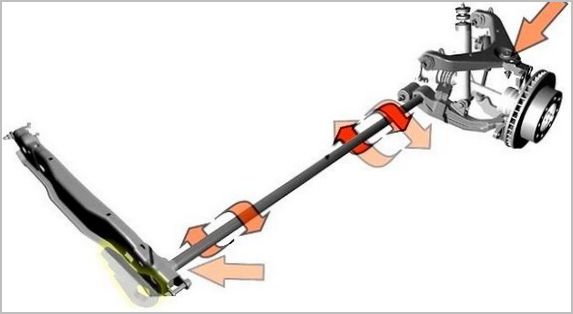

Sometimes, for layout reasons, in automobile suspensions it is undesirable to use known spring elastic elements or coiled coil springs. Another type of such devices are torsion bars. These are spring steel rods or sets of flat sheets working in torsion. One end of the torsion bar is fixed to the frame or body, and the other is clamped to the suspension arm. When the wheel moves, angular twisting of the torsion bar occurs.

Beginning of application on cars and continuation at the present time

There are no fundamental differences in the behavior of correctly calculated torsion or spring suspensions. The topic of torsion bars in relation to ensuring smooth running has been known for a long time, they were widely used in the first half of the last century in army armored vehicles and are still in use. Layout considerations were important there, when a large number of track rollers of tracked vehicles had to be supplied with individual suspensions. There was simply nowhere to place classic springs and springs, and the transverse rods successfully fit in the lower part of the hull of a tank or armored car, without occupying the limited internal space of a combat vehicle. And that means not imposing the burden of additional mass costs on booking the space occupied by the suspension.

Around the same time, the French automakers from the Citroen company used torsion bars on their cars. We also appreciated the positive experience of other companies, suspensions with twisting rods have firmly taken their place in the car chassis. Their use on many models for almost a hundred years indicates the absence of fundamental shortcomings and the presence of advantages.

Torsion assembly design

The suspension was based on a torsion bar - a rod or package made of special steel, round or rectangular, subjected to a very complex heat treatment. This is due to the fact that its dimensions in length are still limited by the parameters of the car, and the twisting of massive metal parts occurs according to complex physical laws. It is enough to imagine how the sections of the rod located inside and outside behave in this case. And under such conditions, the metal must withstand constant alternating loads, not accumulate fatigue, which consists in the appearance of microcracks and irreversible deformations, and maintain the dependence of the elastic forces on the twisting angle stably over many years of operation.

Such properties are provided, including the preliminary capping of the torsion bar. It consists in the fact that the hot rod is preliminarily twisted in the desired direction beyond the yield strength of the material, after which it is cooled. Therefore, the right and left suspension torsion bars with the same dimensions are usually not interchangeable due to the different orientation of the captive angles.

For fixation on the levers and the frame, the torsion bars are equipped with splined or other forms of heads. The thickenings are selected in such a way as not to create weak spots closer to the ends of the rod. When actuated from the side of the wheel, the suspension arm converts the linear movement into a torque on the rod. The torsion bar twists, providing a counter force.

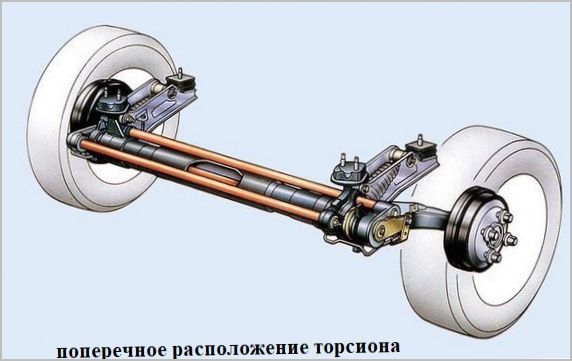

Sometimes the rod is made common for a pair of wheels of the same axle. In this case, it is fixed on the body in its middle part, the suspension becomes even more compact. One of the drawbacks is eliminated when long torsion bars across the entire width of the car are located side by side, and the arms of the levers on the left and right turn out to be of different lengths.

Various designs of torsion bar suspensions

Twisting rods can be used in all known types of suspensions, even telescopic MacPherson struts, which are maximally oriented towards coil springs.

Torsion bars in independent suspensions

Various layout options are possible:

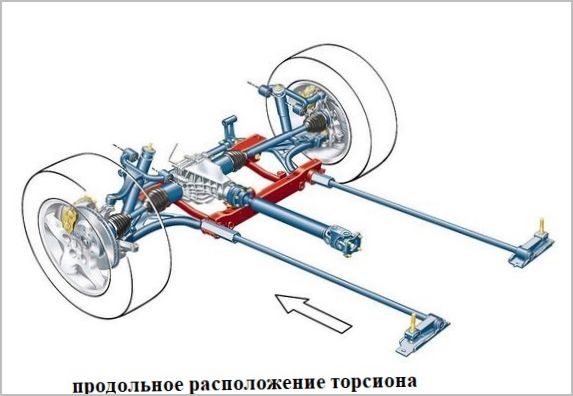

- front or rear suspension on double transverse levers, torsion bars are connected on the axis of rotation of the upper or lower arm, having a longitudinal orientation relative to the vehicle axis;

- rear suspension with longitudinal or oblique arms, a pair of torsion bars is located across the body;

- rear suspension with a twisting semi-independent beam, the torsion bar is located along it, providing the necessary elasticity and reducing the requirements for the material of the beam itself;

- the front suspension with double trailing arms, thanks to the transverse torsion bars, is as compact as possible, convenient for use on microcars;

- torsion bar rear suspension with swinging transverse levers and a longitudinal arrangement of elastic elements.

All types are quite compact, allow simple height adjustment of the body, sometimes even automatic using servo pre-twisting of the rods. Like all other types of mechanical suspensions, the torsion bar is equipped with independent telescopic shock absorbers to dampen vibrations and a guide vane. The rods themselves, unlike, for example, springs, cannot combine functions.

Anti-roll bars also work according to the torsion principle, and there is practically no alternative here.

Advantages and disadvantages

The main advantage is the ease of layout. The elastic rod practically does not take up space under the bottom, unlike a pair of coil springs. At the same time, it provides a similar smooth ride. In operation, it is possible to increase the interference with aging and deformation of parts.

The disadvantage lies in the complex technology for the production of reliable parts, and hence the high price. The torsion bar is about three times more expensive than a good spring for a similar car. And buying a used one is not always justified due to the accumulated metal fatigue.

Despite the compactness of such suspensions, it is not always convenient to place long rods under the bottom of the car. This is easy enough to do in the case of an SUV, but the floor of the car body is located as close to the road as possible, and for the suspension there is only a place in the wheel arches, where coil springs are more appropriate.