The device of steering rods and trapezoids of the car

Content

The levers and rods located after the bipod of the worm steering mechanism and the rack and pinion output connectors form the steering drive system of the steered wheels. If all the mechanics above it are only responsible for creating the necessary force, its direction and magnitude of movement, then the steering rods and auxiliary levers form the geometry of each steered wheel following its own trajectory. The task is not easy, if we remember that the wheels move along their own arcs of circles, which differ in radii by the size of the car track. Accordingly, the turning angles must be different, otherwise the rubber will begin to slip, wear out, and the car as a whole will not adequately respond to control.

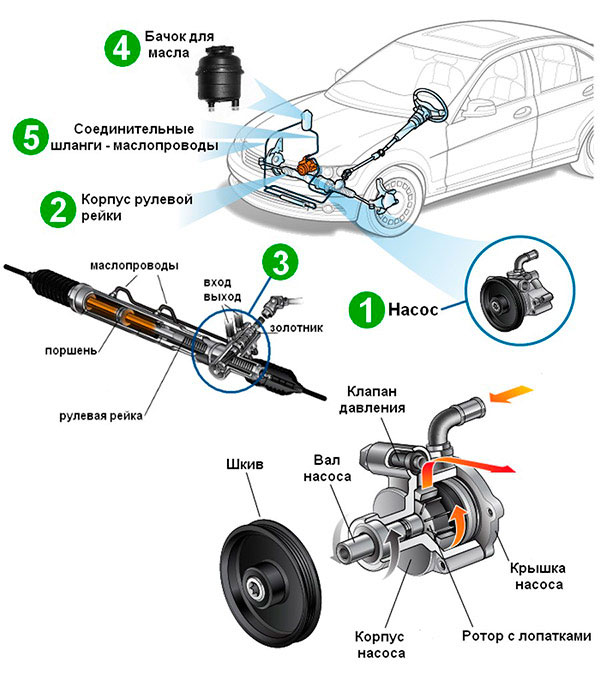

What are power steering systems?

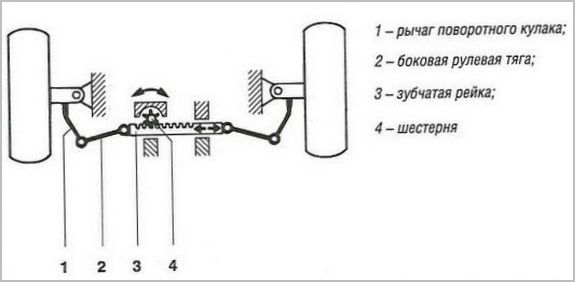

The rack and pinion and worm gears have a different design of drive rods. In the second case, it is customary to call it a trapezoid, and for the simplest "whiskers" emerging from the rail, a short name has not been invented.

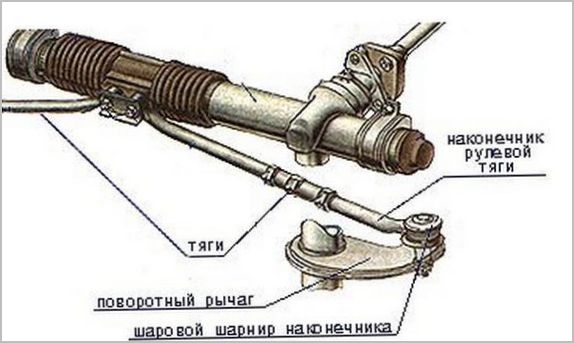

Rack and pinion tie rods

The simplicity of the rail was also manifested in the design of the traction system. Except for the swing arms, which are more related to the suspension, the whole set consists of four elements - two rods with ball joints and two steering tips, also of a ball design, but differently spatially oriented. For individual details, the nomenclature is wider:

- steering rods, most often the same on the left and right, are supplied with spherical tips;

- from external influences, the hinges of the rods are protected by corrugated anthers, at a price sometimes comparable to rods;

- between the rod and the tip there is a toe-adjustment clutch with lock nuts;

- the steering tip is usually non-separable, the right one is a mirror image of the left one, it includes a body, a pin with a sphere, an insert, a spring and a rubber boot.

The geometry allows the wheels to turn at different angles, as described above.

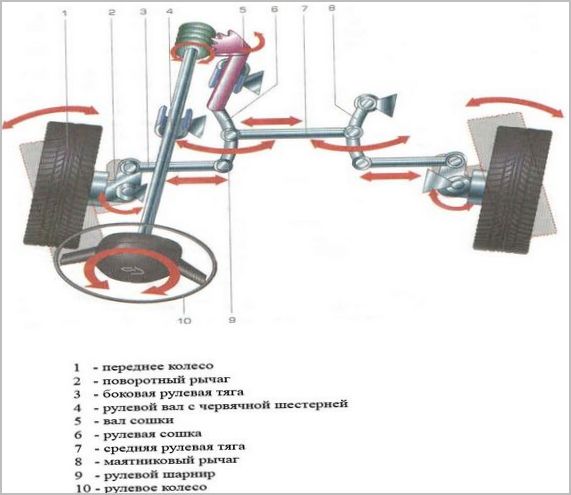

Steering trapezoid worm or screw gearboxes

This is where things get more complicated:

- steering rods are usually three, left, right and central, there are also more complex designs;

- each rod begins and ends with steering ball tips, and the extreme ones are made collapsible due to the presence of the same toe adjustment couplings in the section, so we can talk not about two extreme rods, but about four steering tips, sometimes they are supplied in this form, subdivided into internal, external, left and right;

- one more element was introduced into the design, making the trapezoid symmetrical, from the side opposite to the longitudinal axis of the body from the bipod of the main gearbox, a pendulum lever with the same bipod is installed, the central and extreme thrusts are attached to it.

The trapezoid is similarly connected to the swing arms, rigidly mounted on the fists of the hub nodes. The rotation of the fists is carried out in two ball bearings of the suspension.

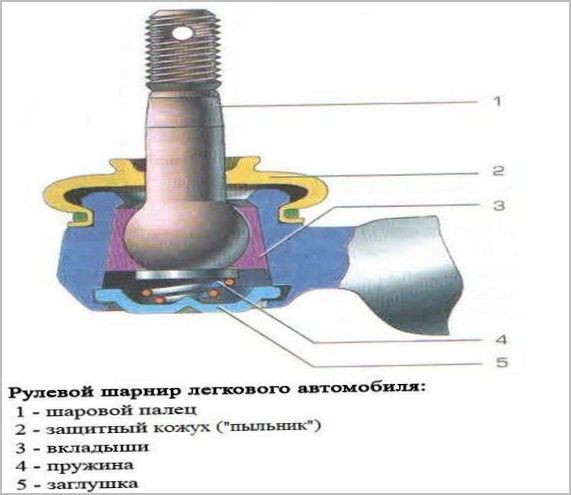

Steering ball joints

The basis of all joints of the drive are ball joints (SHS), which can rotate relative to the axis of the finger and swing in all planes, rigidly transferring force only in the right direction.

In obsolete designs, loops were made collapsible, which meant their repair with the replacement of nylon liners. Then this idea was abandoned, as well as the presence of grease fittings on the loop to replenish the lubricant. The tip is considered a consumable, relatively easy to replace and inexpensive, so repair is considered inappropriate. At the same time, the operation for regular injection of hinges was eliminated from the TO list. So it is more reliable and safer, driving with a repaired hinge is fraught with a disconnection of traction at speed with disastrous consequences.

A typical case of repair is to overhaul the drive with the replacement of all loops, after which the system is completely updated and safety is guaranteed. It is only necessary to pay attention to the safety of rubber covers when inspecting the chassis during routine maintenance. Depressurization of ball tips immediately leads to their failure, since there is a lubricant inside that quickly attracts abrasive dust and water. Backlash appears in the tips, the chassis begins to knock, it becomes dangerous to drive further.