Types of slipway for body repair

Content

Car body repairs often require expensive materials. But the deformation of the parts does not mean that they need to be replaced. You can restore the geometry of the body by contacting the workshop. But the services of the workers will have to be paid. Or you can create a slipway and repair the machine yourself. Homemade butts for body repair have a huge number of advantages.

What is the purpose of the principle of operation

A harrow is a piece of equipment needed to fix a bent car body. But, depending on the type of device, large machines are also repaired. Its purpose is smoothing and correction.

The principle of operation is to apply force to a securely fixed machine. For this, chains or other devices are used to restore the necessary body geometry.

Types of stocks and their main differences

In total there are 4 types of construction:

- Floor. Standard design on rails.

- Lamination small in size Similar designs are stored in a garage or workshop.

- Framework. Structures on chains are designed for complete repair and lifting of the machine in height.

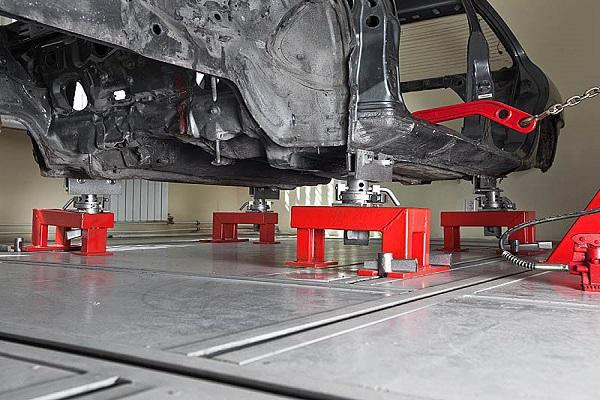

- Platform. Designed for professional repair. Suitable for large vehicles.

Floor structures

The floor harrow is also called stationary. Their difference is in the presence of rails on the floor, which allow you to move the mechanisms. It makes it easy to do body work.

The stationary harrow is convenient thanks to retractable mechanisms.

Floor structures have 3 advantages:

- They take up little space.

- They are cheaper than other actions.

- Fast transport installation.

The disadvantage is the complexity of the installation of the structure.

Rolling

An extension harrow is a harrow used for light repair work, if a full harrow is not available or its use is impossible for some reason. The difference is that the stands are small in size; you don't have to drive the car to it. You can bring a rolling harrow to the car.

This design has the following advantages:

- It is customizable for different types of vehicles.

- Possibility of equipping the device with hydraulics.

- The design of fastening with a clamp has no analogues.

- It can be used with most types of machines.

- Compact size.

The disadvantage is the inability to perform complex work associated with large distortions.

frame

A distinctive feature of frame structures is the use of a frame as a basis. The car is secured with chains. Most often, such a design is used for minor repairs. But at the same time, the structure of frame stocks is more complicated than others. Clamps are attached to them, which allow you to fix the car body in the required position or even raise it to a certain height.

Platform models

The platform model is very similar to the overpass model. It allows you to pull the car body in any direction. A lot of different equipment can be installed on the slipway platform. Pulling out the platform is very convenient, and the functionality is enough for professional repairs right in the garage.

Tools and materials for creating a structure

We will need the following materials and tools:

- metal profiles.

- Extended profiles (required for racks).

- metal corners

- Welding machine.

- Screws and nuts.

- Clamping mechanisms.

- Paint and primer.

- Chains and hooks.

- Hydraulic equipment.

- Airbrush.

- Power support.

Step by step instructions for building

The construction of any home-made structure begins with the design stage. You need to make a harrow that will be convenient to use. It is important that it does not take up too much space, blocking free movement.

The second point is always the creation of a framework structure. The last point is the installation of fasteners and clamping devices with your own hands.

Drawings and dimensions

First you need to make suitable drawings. Ready-made options can be found below. Marking is carried out according to the dimensions of the car. Then the stage of preparation and selection of tools and materials begins. We will also need to make a sufficiently large mounting system suitable for our transport. It will be nice to cook it with the ability to change the height.

- Once all the drawings are ready and the materials are selected, you can get to work. First you need to remove moisture from the materials and cover them with a primer. You can color them right away or leave this step for last.

- Now weld the metal corners to the main profile.

- Weld the profile (this will be the support). It is fixed with screws.

- Chains, hooks and drawers are now welded.

Frame manufacturing

The frame is responsible for fixing the car. Therefore, when creating it, you need to be careful.

- Before creating a frame, you must create an outer frame. It is to him that the frame will be attached.

- A metal profile is suitable as a material. A rack and clamps are attached to it (they are needed to fix the threshold of the car).

- Thresholds are being made now. They are made from metal corners.

- Thresholds are installed on beams, fixed with bolts.

- After installation, you will need to repair all elements by welding.

Fastening the body to the slipway

Clamps are required for fixing. If you can't buy them, make your own. You will need rail platforms (which rails are attached to the sleepers). Each of the platforms is cut in half, and the metal is welded from the inside. On a grinding machine cut into diamonds.

You don't have to do anything with the outside. A plate, 4 mm thick, is also welded inside. It is important that the clamping device fixes the window sill and does not bend during use.

Installing the rack and pulling devices

Factory hydraulic fittings are suitable for racks and mounts. If they cannot be purchased, a homemade mechanism will do. The power of the device should be from 1 to 2 tons. The overlap is necessary to connect the traction devices. It is made of a channel and mounted on a stand frame. To place the tensioner and chains anywhere, it is necessary to drill the frame along the riser.

If the rack is made independently, it is recommended to use a tower device. It's hard, but the recovery of the car will be smooth.

Making a stand is not that difficult. If you have basic knowledge in construction, you can easily do everything yourself. The main thing is to choose the right material and make the right drawings.